Aluminium alloy chromium-phosphorus-free nanoscale chemical conversion liquid for ships and method for preparing conversion film

A chemical conversion coating and chemical conversion technology, applied in the field of marine aluminum alloy decoration and protective coating, can solve problems such as environmental pollution, and achieve the effect of good corrosion resistance and good organic coating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below through the drawings and examples, but not limited.

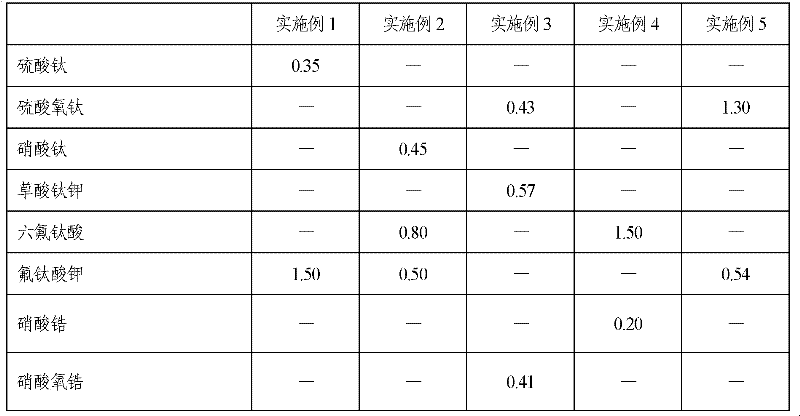

[0028] The marine aluminum alloy chromium-free and phosphorus-free nanoscale chemical conversion liquid of the present invention contains titanium salt, zirconium salt, silicon compound, accelerator, pH regulator, surfactant, etc., and the conversion liquid is titanium salt, zirconium salt, silicon compound, Accelerator, pH adjuster, and surfactant are evenly mixed. The marine aluminum alloy chromium-free and phosphorus-free nano-scale chemical conversion liquid of the present invention is used to form a chromium-free and phosphorus-free chemical conversion film. The film-forming process steps of the chromium-free and phosphorus-free nano-scale chemical conversion film are: degreasing→water washing→acid etching→water washing→ Chemical transformation→washing→drying.

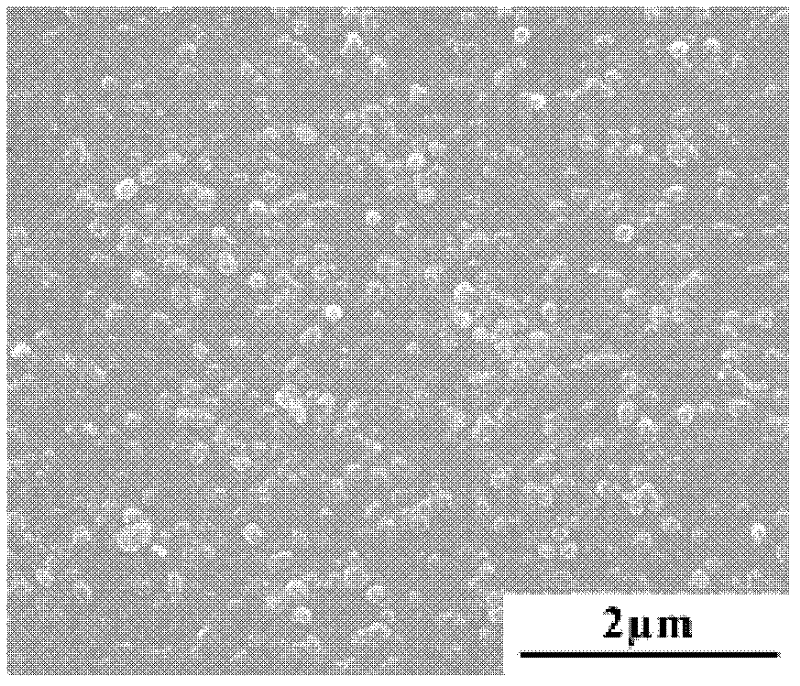

[0029] After the aluminum alloy is degreased, washed with water, acid-etched, and washed with w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com