Self-levelling underlayment material

A cement and leveling technology, applied in the field of new chemical materials for roads and bridges, can solve problems such as floor cracks and affecting the service life of cement self-leveling floors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the cement self-leveling floor of the present invention is a method well known to those skilled in the art, and specifically can be prepared as follows:

[0044] 40-100 parts by weight of sand, 40-100 parts by weight of cement, 2-30 parts by weight of gypsum, 2-30 parts by weight of inorganic fluoride, 0.1-15 parts by weight of water reducing agent, 4-15 parts by weight of The expansion agent, 0.1-10 parts by weight of viscosifying water-retaining agent and 0.1-15 parts by weight of fiber are placed in a mixer and mixed at room temperature for 5-60 minutes to obtain dry powder of cement self-leveling floor material;

[0045] Add a certain amount of water to the dry powder of cement self-leveling floor materials, and the weight ratio of dry powder to water is preferably 100: (25-45);

[0046] The cement self-leveling floor material slurry obtained above is evenly spread on the construction ground, and maintained for 3 to 28 days to obtain an env...

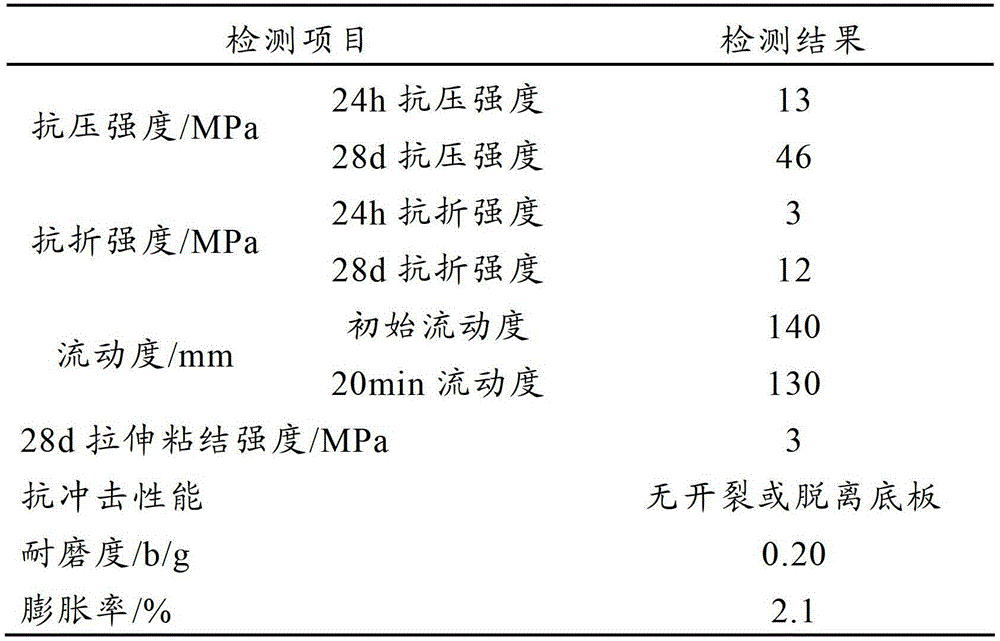

Embodiment 1

[0051] Accurately weigh 4.5kg river sand and 4.5kg quartz sand, 5kg P.O42.5 Portland cement, 5kg Shuangkuai-150 sulfoaluminate cement, 0.2kg hemihydrate gypsum, 0.8kg mixture of fluorogypsum, 0.3kg dry powder type polycarboxylate superplasticizer, 0.1kg redispersible latex powder HW5115, 0.2kg hydroxypropyl methylcellulose, 0.2kg polyvinyl alcohol 1788, 0.5kg sodium fluoride , 0.5kg of calcium oxide expansion agent and 0.5kg of glass fiber are placed in a high-speed mixer and mixed for 20 minutes before being discharged. The material test performance is shown in Table 1.

[0052] According to the test method of JC / T-985 cement-based self-leveling mortar for ground, the results are shown in Table 1:

[0053] The performance data table of the cement self-leveling floor material prepared by the embodiment 1 of table 1

[0054]

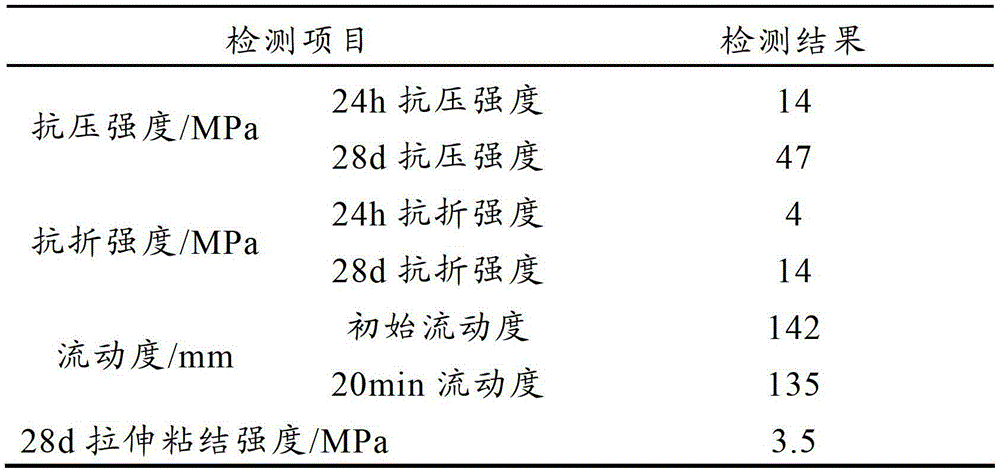

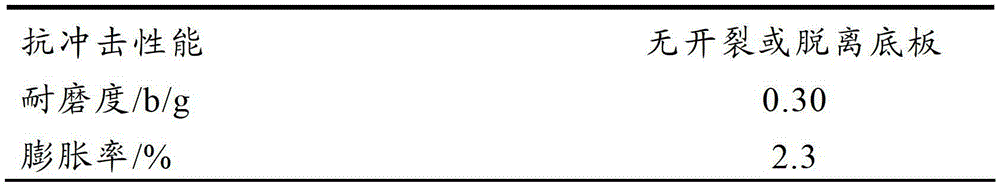

Embodiment 2

[0056] Accurately weigh 3kg of river sand and 1kg of quartz sand, 2kg of aluminate cement and 2kg of iron-aluminate cement, 3kg of fluorogypsum, 2kg of magnesium fluoride, 1kg of calcium fluoride, and 1.0kg of amino acid with a particle size of 0.10mm to 0.50mm. Water reducer, 0.5kg polycarboxylate water reducer, 1.2kg calcium sulfoaluminate expansion agent, 0.3kg magnesium oxide expansion agent, 0.5kg polyvinyl alcohol 1788, 0.5kg lignin, 1.0kg asbestos fiber and 0.5kg seawater The foam stone fiber is discharged after being placed in a high-speed mixer and mixed for 20 minutes.

[0057] According to the test method of JC / T-985 cement-based self-leveling mortar for ground, the results are shown in Table 2:

[0058] The performance data sheet of the cement self-leveling floor material prepared by the embodiment 2 of table 2

[0059]

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com