Method for preparing aluminium borate whisker preform

A technology for aluminum borate whiskers and preforms, which is applied in the field of preparation of aluminum borate whiskers preforms, can solve the problems of long time consumption, high energy consumption, increased production costs and the like, and achieves the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: the preparation volume is Aluminum borate whisker cylindrical preform with volume fraction of aluminum borate whisker 30%.

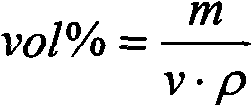

[0017] (1) According to the volume fraction formula: vol % = m v · ρ Calculate the mass m of the aluminum borate whiskers required, where vol% is the whisker volume fraction, v is the whisker volume, and ρ is the whisker density. Weigh 44.7g of aluminum borate whiskers and 2.3g of aluminum phosphate as a binder, put them into a stirrer respectively, add 448ml of water and 90ml of sodium polyacrylate with a mass concentration of 3‰ into the stirrer as a dispersant.

[0018] (2) Adjust the rotational speed of the agitator to 180 rpm and stir for 30 seconds, pause for 60 seconds, stir again for 30 seconds, pause for 60 seconds, stir again for 30 seconds to obtain a mixed slurry.

[0019] (3) Filter and remove 80% o...

Embodiment 2

[0023] Embodiment 2: the preparation volume is Aluminum borate whisker cylindrical preform with volume fraction of aluminum borate whisker 25%.

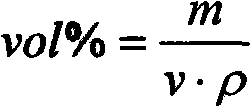

[0024] (1) According to the volume fraction formula: vol % = m v · ρ Calculate the mass m of the aluminum borate whiskers required, where vol% is the whisker volume fraction, v is the whisker volume, and ρ is the whisker density. Weigh 37.3g of aluminum borate whiskers and 1.9g of aluminum phosphate as a binder, put them into a stirrer respectively, add 373ml of water and 75ml of sodium polyacrylate with a mass concentration of 4‰ into the stirrer as a dispersant.

[0025] (2) Adjust the rotational speed of the agitator to 200 rpm and stir for 30 seconds, pause for 90 seconds, stir again for 30 seconds, pause for 90 seconds, stir again for 30 seconds to obtain a mixed slurry.

[0026] (3) Filter and remove 80% o...

Embodiment 3

[0030] Embodiment 3: the preparation volume is The aluminum borate whisker cylinder prefabricated body whose volume fraction of aluminum borate whiskers is 20%.

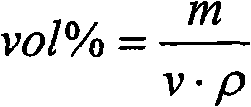

[0031] (1) According to the volume fraction formula: vol % = m v · ρ Calculate the mass m of the aluminum borate whiskers required, where vol% is the whisker volume fraction, v is the whisker volume, and ρ is the whisker density. Weigh 29.8g of aluminum borate whiskers and 1.5g of aluminum phosphate as an adhesive, put them into a stirrer respectively, add 298ml of water and 60ml of sodium polyacrylate with a mass concentration of 5‰ into the stirrer as a dispersant.

[0032] (2) Adjust the rotation speed of the stirrer to 210 rpm and stir for 30 seconds, pause for 120 seconds, stir again for 30 seconds, pause for another 120 seconds, stir again for 30 seconds to obtain a mixed slurry.

[0033] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com