Preparation method for high-dispersibility high-viscosity magnesium aluminum silicate inorganic gel

A technology of magnesium aluminum silicate and inorganic gel, applied in the direction of aluminum silicate, silicate, etc., can solve the impact of production efficiency and production cost of application manufacturers, restrict the application of magnesium aluminum silicate inorganic gel, and the dispersion time of water system Change the length and other issues to achieve the effect of wide applicability, easy implementation and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

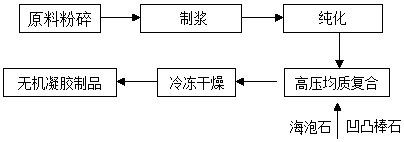

Method used

Image

Examples

Embodiment 1

[0030] S1, crushing the natural calcium-based bentonite to a particle size of 2mm;

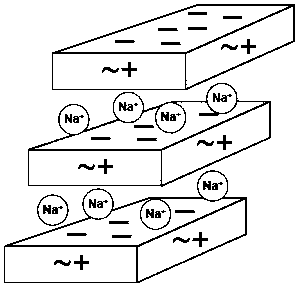

[0031] S2, take 50g of raw materials and add 2% sodium carbonate according to the mass percentage, add water to configure 10% ore slurry, stir and disperse for 45min;

[0032] S3, set the dynamic gravity centrifuge, the separation factor is 2047, and centrifuge the pulp for 6 minutes;

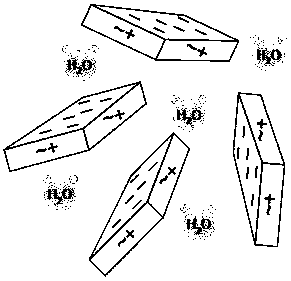

[0033] S4, add 5% attapulgite to the suspension obtained by separation, set the pressure of the high-pressure homogenizer to 180MPa, and perform homogenization and compounding;

[0034] S5. Freeze-dry at -40°C to a solid content of 97% to obtain a finished product.

Embodiment 2

[0036] S1, crushing the natural calcium-based bentonite to a particle size of 2 mm;

[0037] S2. Take 50g of raw materials and add 3% sodium carbonate according to the mass percentage, add water to form a 12% slurry, stir and disperse for 45min;

[0038] S3. Add water to adjust the concentration of the pulp to 8%, set the separation factor to 1590, and centrifuge the pulp for 4 minutes;

[0039] S4, adding 2% sepiolite and 3% attapulgite to the suspension obtained by separation, and setting the pressure at 150MPa for homogenization and compounding;

[0040] S5. Freeze-dry the pulp at -40°C to a solid content of 98% to obtain a finished product.

[0041] Tests show that the magnesium aluminum silicate inorganic gel treated by the present invention has a 1% water dispersion time≦5min, and a 5% water dispersion viscosity≧1500mpa.s after standing still for 24 hours.

[0042] Data comparison:

[0043]

[0044] The comparison gel (magnesium aluminum silicate inorganic gel) in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com