Fat-soluble nutrient microcapsules and preparation method thereof

A technology of fat-soluble nutrients and microcapsules, which is applied in the field of food and feed additives, can solve the problems of loss of nutrients, etc., and achieve the effect of reducing deterioration, high retention rate and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The above preparation method can be carried out under the protection of nitrogen. The use of nitrogen protection can eliminate the influence of oxygen in the environment on nutrients and ensure the stability of fat-soluble nutrients during the preparation of microcapsules.

[0025] The water used in the above water phase can be deoxidized in advance to further eliminate the influence of oxygen in the environment and improve the stability of fat-soluble nutrients in the microcapsule preparation process. In the water phase, the mass ratio of the hydrophilic wall material to water is 0.5-1:1.

[0026] The above-mentioned drying process may be spray drying, spray granulation-fluidized drying and the like.

Embodiment 1

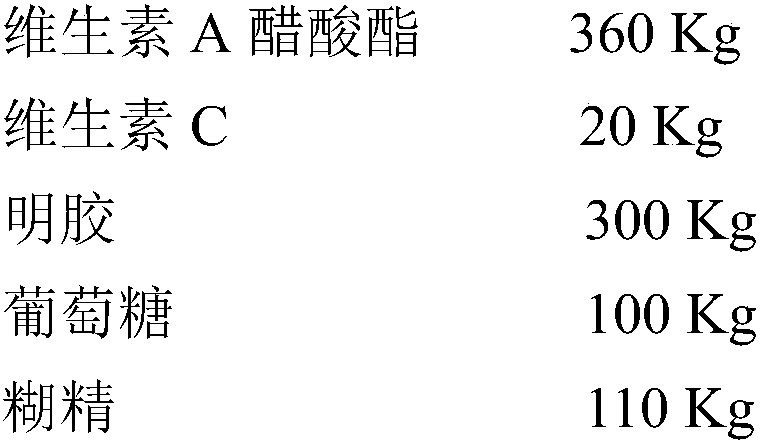

[0029] Vitamin A microcapsule and its preparation

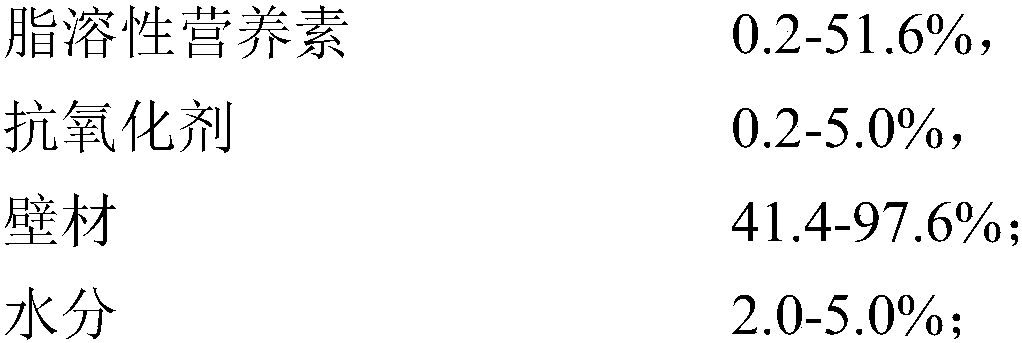

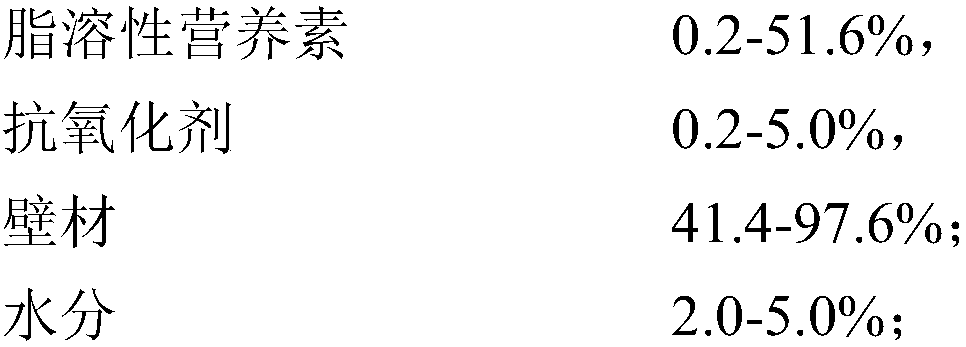

[0030] Components:

[0031]

[0032]Accurately weigh 360Kg of vitamin A acetate crystals, put it into the melting oil kettle, heat up to melt all the materials to obtain molten oil; put 1000L of drinking water into the batching kettle, and then throw in 300Kg of gelatin, 100Kg of glucose, 20Kg of vitamin C, and 110Kg of dextrin. Warm up and stir to dissolve to obtain a hydrosol solution. Use a pump to pump the melted oil in the melting oil kettle and the hydrosol solution in the batching kettle into the 5-stage cavitation emulsifier in series with a high-pressure pump, adjust the pressure to 400Mpa, and carry out continuous emulsification to obtain vitamin A acetate emulsion at the outlet , the emulsion is continuously fed into a spray granulation tower sprayed with cornstarch for granulation, and then fluidized and dried to obtain vitamin A acetate particles, and the vitamin A acetate retention rate in the production pro...

Embodiment 2

[0034] Vitamin D3 microcapsules and its preparation

[0035] Components:

[0036]

[0037] Put 55Kg of vitamin D3 oil into the melting oil kettle, add 5Kg of BHT to the kettle, heat up to melt all the materials to obtain molten oil; put 980L of drinking water into the batching kettle, and then put in 200Kg of white sugar, 150Kg of gelatin, and 630Kg of dextrin, Warm up and stir to dissolve to obtain a hydrosol solution. Use a pump to pump the melted oil in the above-mentioned melting oil tank and the hydrosol solution in the batching tank into the 4-stage series cavitation emulsifier with a high-pressure pump, adjust the pressure to 200Mpa, and carry out continuous emulsification to obtain vitamin D3 emulsion at the outlet. The emulsion is continuously passed into a spray drying tower for spray drying to obtain vitamin D3 dry powder, and the calculated retention rate of vitamin D3 in the production process is 99.2%. The vitamin D3 dry powder was placed at 25°C for a stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com