Aromatic vinyl ether based reverse-tone step and flash imprint lithography

a reverse-tone, lithography technology, applied in the field of step and flash imprint lithography, can solve the problems of inability to fully exclude molding or imprint material from template and substrate, range from extremely challenging to impossible, and complicate the process justly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

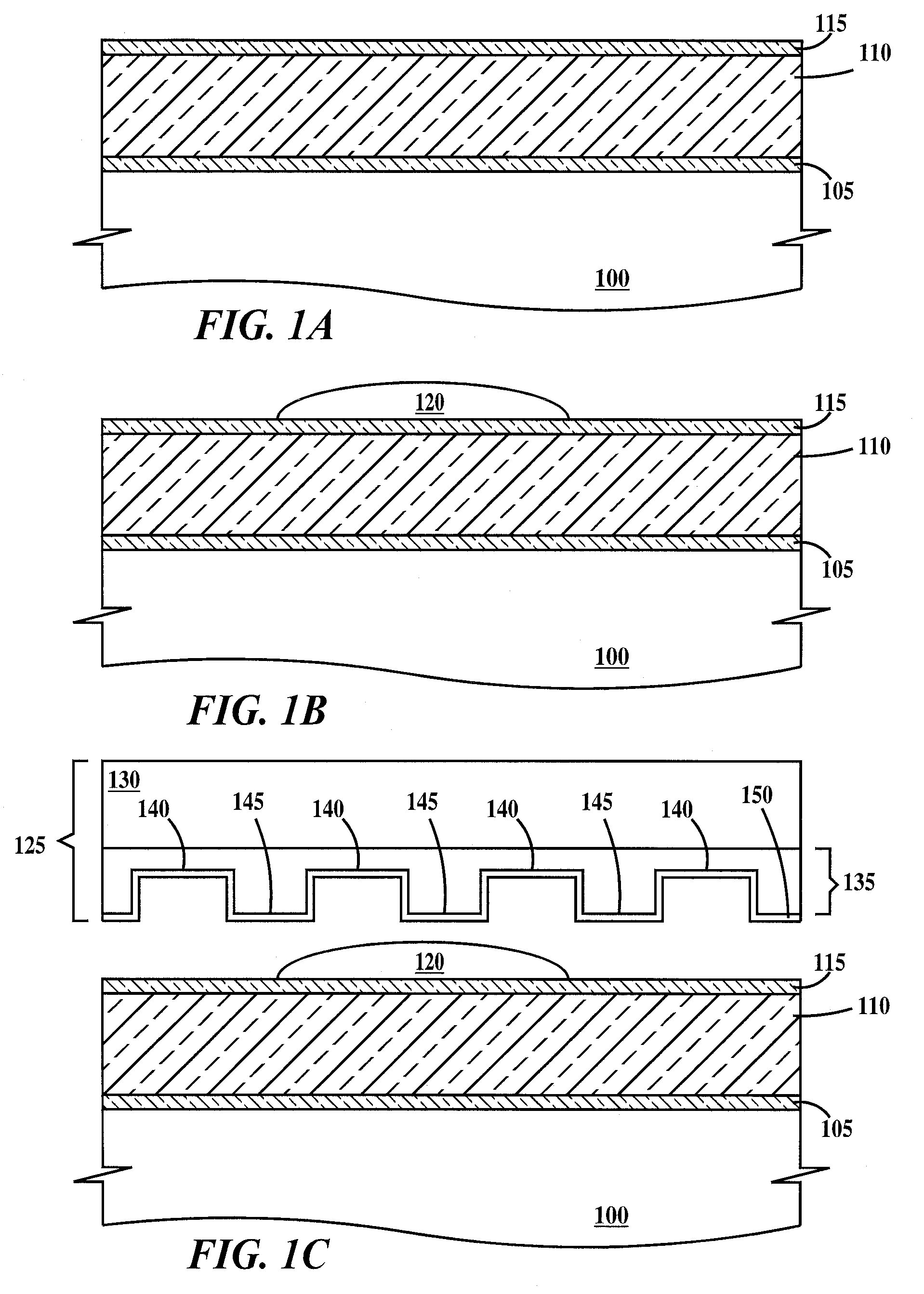

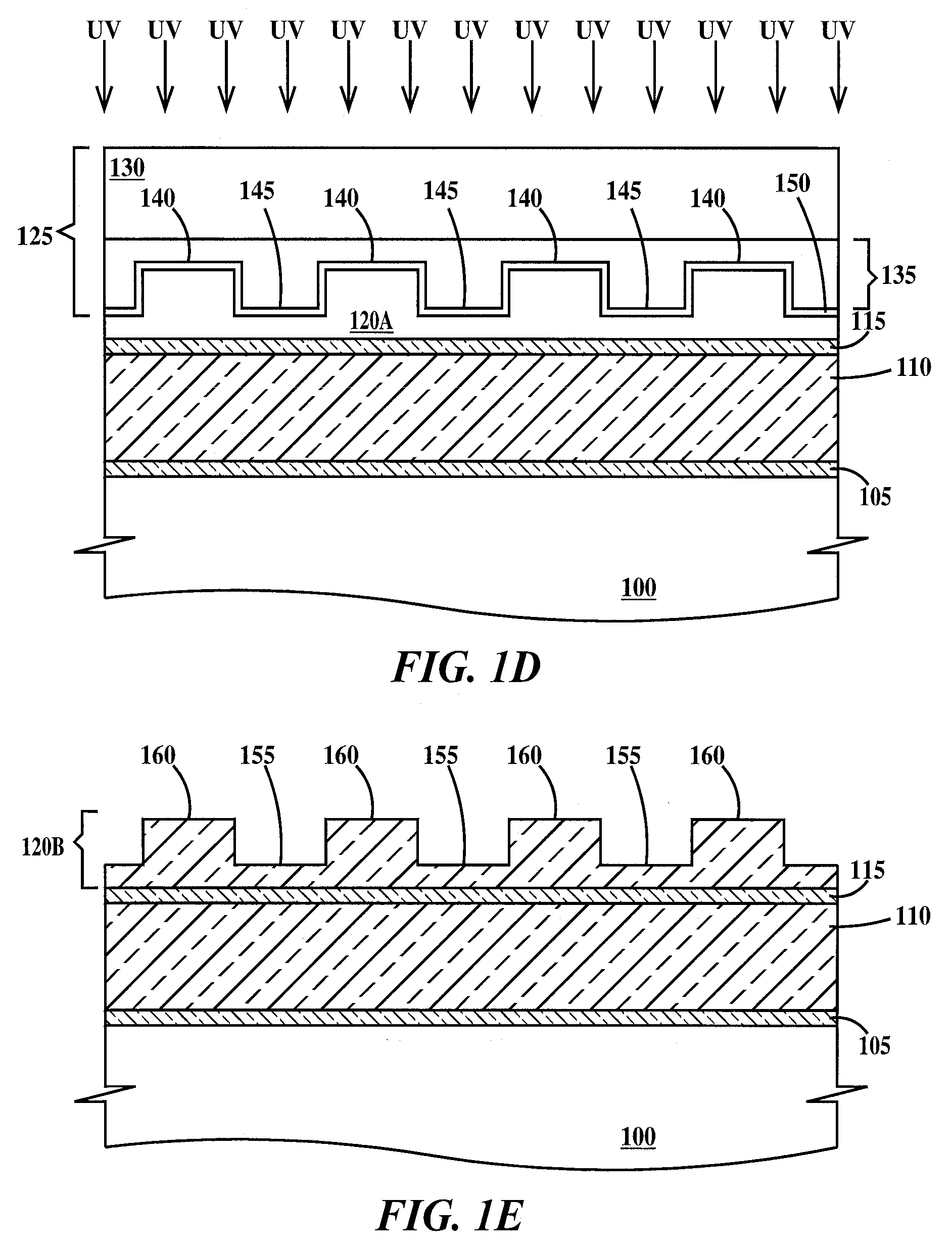

first embodiment

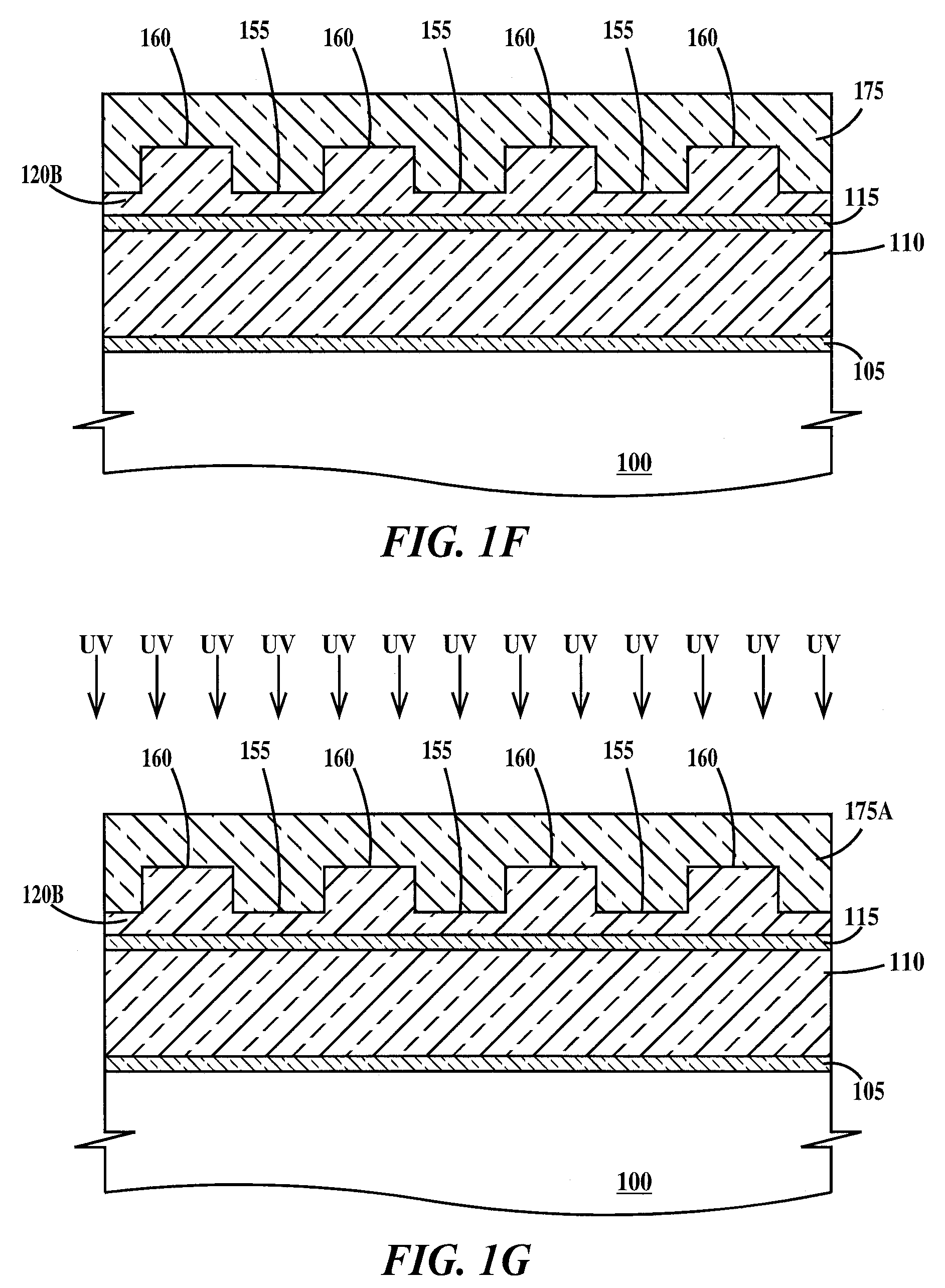

[0064]Thus, the pattern of plateaus 145 of template 125 (see FIG. 1C) has been converted to a pattern of trenches 190 in substrate 100 (see FIG. 1I) in a negative imaging process in the present invention without the use of a residual layer removal or pre-burning step.

second embodiment

[0065]FIGS. 2A through 2K are cross-sectional drawings illustrating a SFIL process according to the present invention. In FIGS. 2A through 2J, adhesion layer 115 is optional and its composition has been described supra. FIG. 2A is similar to FIG. 1A, FIG. 2B is similar to FIG. 1B, and FIG. 2C is similar to FIG. 1C, except there is no transfer layer or second adhesion layer and puddle of molding composition 120 is formed on the top surface of adhesion layer 115 or the top surface of substrate 100 if no adhesion layer is used. An advantage of using aromatic vinyl ethers in the molding composition is that a single layer of material can serve as both the molding layer and the transfer layer, eliminating the need to apply a separate aromatic transfer layer.

[0066]FIGS. 2D, 2E, 2F, 2G and 2H are similar to FIGS. 1D, 1E, 1F, 1G and 1H respectively. In reference to FIG. 2E, the triethoxysilyl moiety of adhesion layer 115 (structure I) reacts with the —OH group on the surface of substrate 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com