Porous carbon nanometer fiber-supported nanocrystal catalyst and preparation method thereof

A technology of nanofibers and nanocrystals, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of loss of photocatalytic activity, high energy consumption, unsuitability, etc., and achieve energy saving Consumption, reduction of production cost, effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

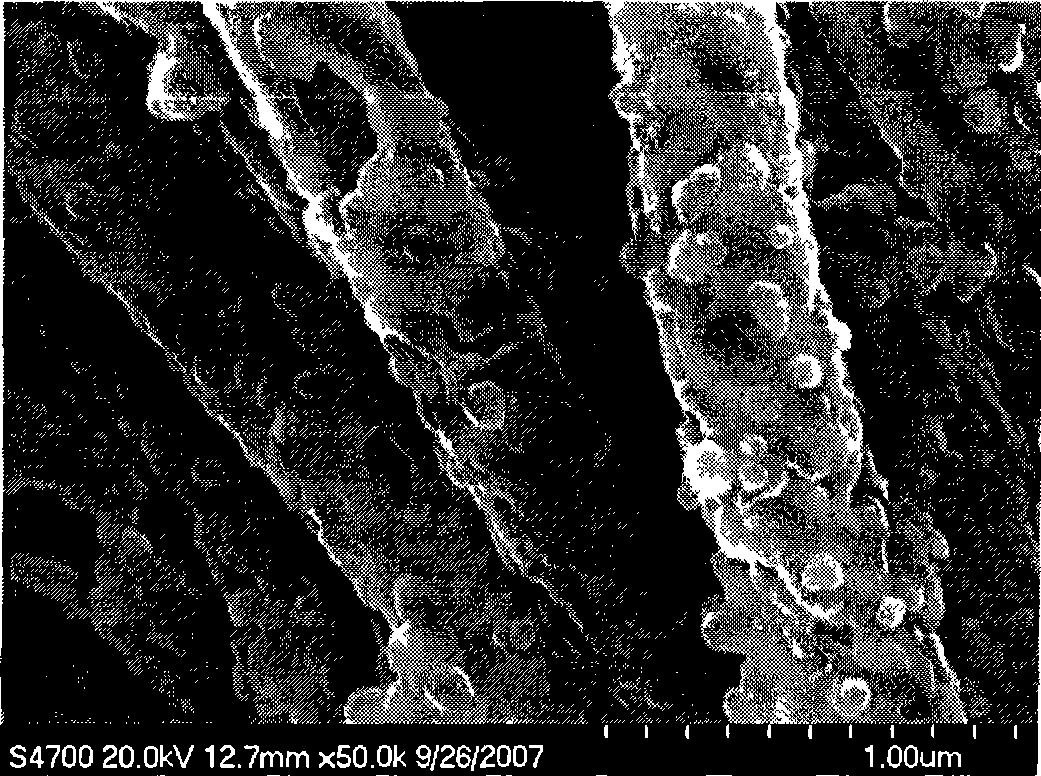

[0028] 8 mL of tetrabutyl titanate was dissolved in 50 mL of polyacrylonitrile / dimethylformamide solution with a mass concentration of 10%, and then ultrasonically stirred to form a uniform spinning solution for electrospinning. During the electrospinning process, a No. 12 injection needle with an inner diameter of 1.1mm was selected, the applied electrostatic voltage was 15kV, the flow rate of the spinning solution was 0.5mL / h, the receiving distance between the metal cylinder and the needle was 20cm, and the outer diameter of the cylinder was The line speed is 10m / s, and after 5 hours of spinning, a nanofiber mat / membrane with a certain thickness and partially parallel orientation is obtained. The electrospun nanofiber mat / membrane was stretched under constant tension at 135°C for 15min, and the tension applied along the longitudinal direction of the fiber mat / membrane was 10MPa, and then pre-oxidized in air at 250°C for 1h to obtain a stable chemical nanofibers. Finally, t...

Embodiment 2

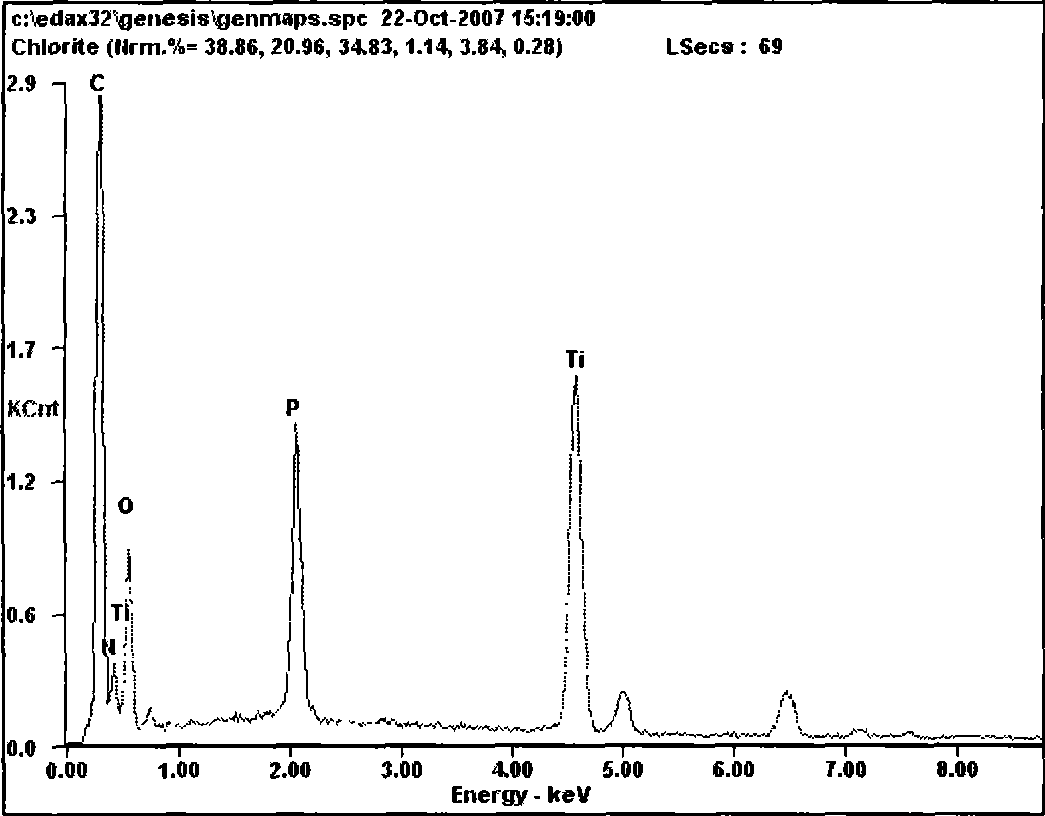

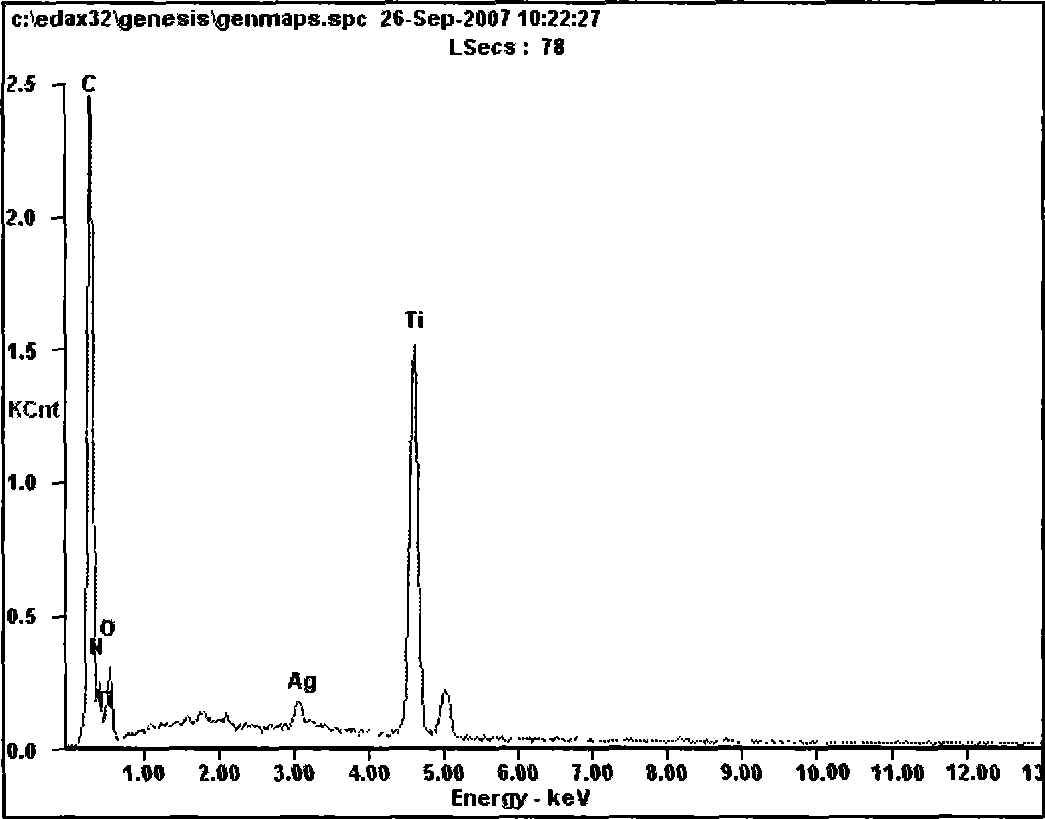

[0030] 8 mL of tetrabutyl titanate and 0.2 g of silver nitrate were dissolved in 60 mL of 10% polyacrylonitrile / dimethylformamide solution, and then ultrasonically stirred to form a uniform spinning solution for electrospinning. According to the electrospinning process, thermal drawing and pre-oxidation process in Example 1, stabilized nanofibers were obtained. Finally, immerse the stabilized nanofibers in a KOH solution with a concentration of 1mol / L for 2h, take them out and place them in an activation furnace at 600°C for 2h under an ammonia atmosphere, the flow rate of ammonia gas is 10mL / min, heating and cooling The speeds are 3°C / min and 10°C / min, respectively, take it out after cooling and wash with 1mol / L HCl solution and deionized water several times, then the porous carbon nanofiber supported silver and titanium dioxide two-component catalyst can be obtained, in which the silver The particle diameter is about 10nm, and the weight percent content is about 2% (see im...

Embodiment 3

[0032] 4 g of silver nitrate was dissolved in 50 mL of polyacrylonitrile / dimethylformamide solution with a mass concentration of 10%, and then ultrasonically stirred to form a uniform spinning solution for electrospinning. During the electrospinning process, a No. 9 injection needle with an inner diameter of 0.9mm was selected, the applied electrostatic voltage was 12kV, the flow rate of the spinning liquid was 0.3mL / h, the receiving distance between the metal cylinder and the needle was 20cm, and the outer diameter of the cylinder was The line speed is 10m / s, and after 5 hours of spinning, a nanofiber mat / membrane with a certain thickness and partially parallel orientation is obtained. The electrospun nanofiber mat / membrane was stretched under constant tension at 135°C for 10min, the tension applied along the longitudinal direction of the fiber mat / membrane was 5MPa, and then pre-oxidized in air at 250°C for 1h to obtain a stable chemical nanofibers. Finally, immerse the sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com