Lead-acid storage battery grid with improved corrosion resisting property and preparation method thereof

A lead-acid battery, corrosion resistance technology, applied in the direction of the electrode carrier / current collector, etc., can solve the problems of thickened surface corrosion layer, poor battery cycle performance, etc., to reduce the hot melting temperature, high feasibility, improve durability The effect of corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

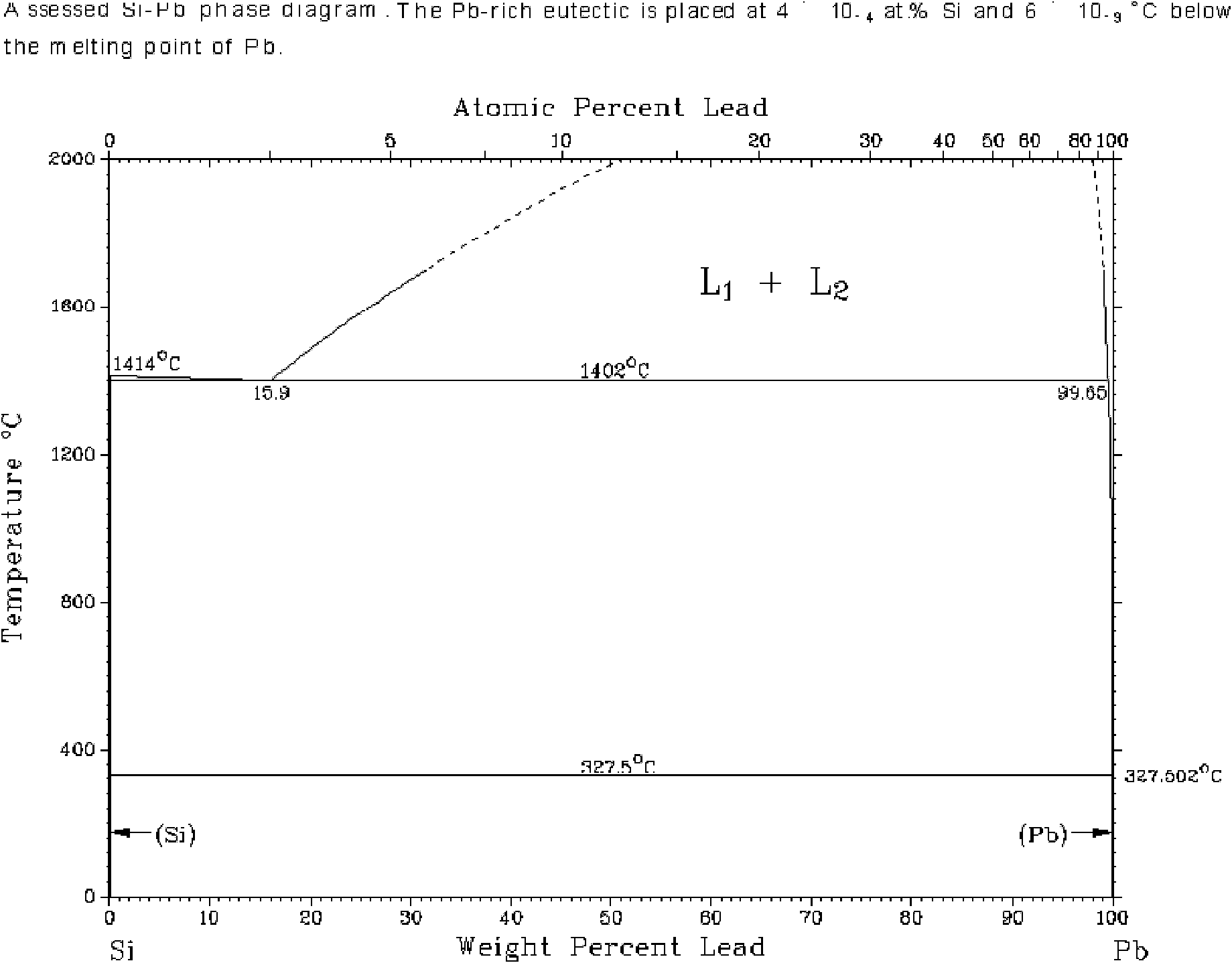

[0023] Alloy material composition: Pb, Sn: 0.3wt.%, Si: 0.03wt.%, and the balance is Pb.

[0024] Si is added in the form of Sn-Si alloy, and it is better if the Sn-Si alloy can be ground into powder. Specifically, the added amount of Si is converted into the amount of Sn—Si through calculation. Then determine the amount of Sn added.

[0025] The following is the specific preparation process:

[0026] (1), each component material is called according to the alloy composition;

[0027] (2) Fully melt the prepared alloy at a temperature of about 500-700°C, cast the grid, and make the grid after cooling.

Embodiment 2

[0029] The ratio between Pb and Sn was the same as in Example 1, and the grid was cast in a conventional manner.

Embodiment 3

[0030] Embodiment 3, to the corrosion experiment of the grid that embodiment 1 and 2 manufacture:

[0031] Corrosion test environment: 60°C water bath, the anode potential of the corrosion grid is 1.35-1.38V (vs Hg / Hg 2 SO 4 electrode), H 2 SO 4 Solution (density: 1.304g / cm 3 , 25°C), and the corrosion time was 129 days.

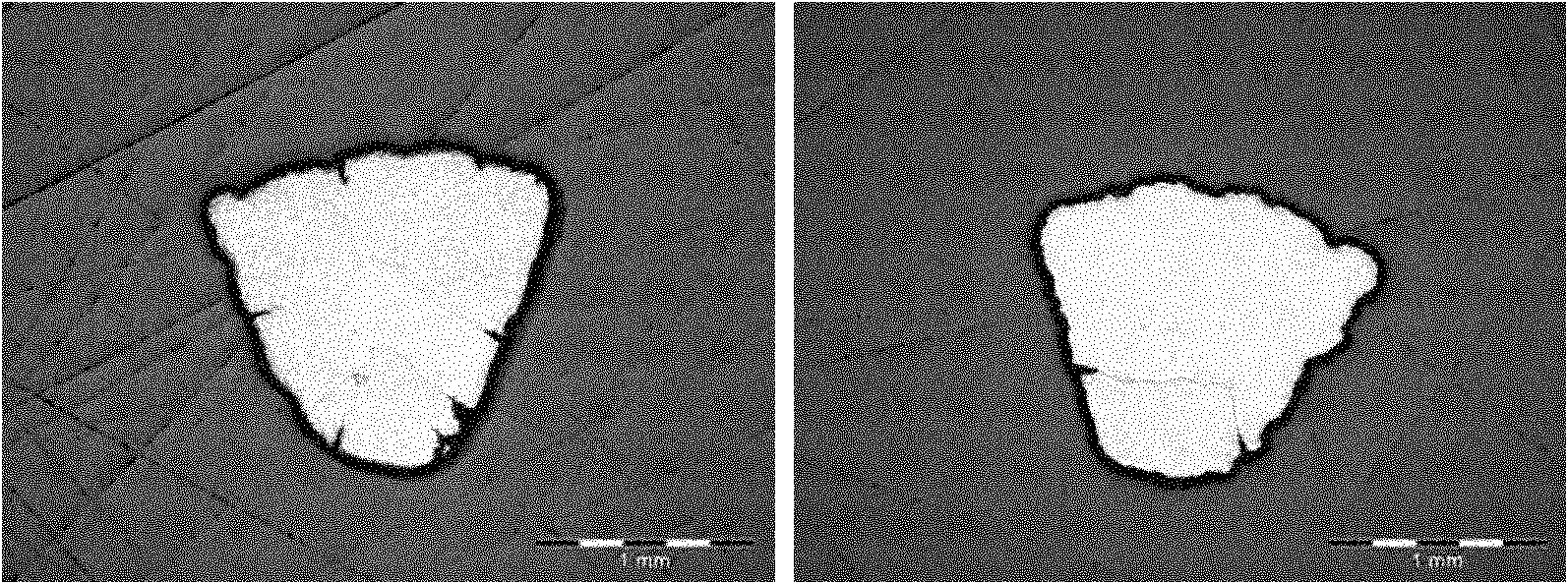

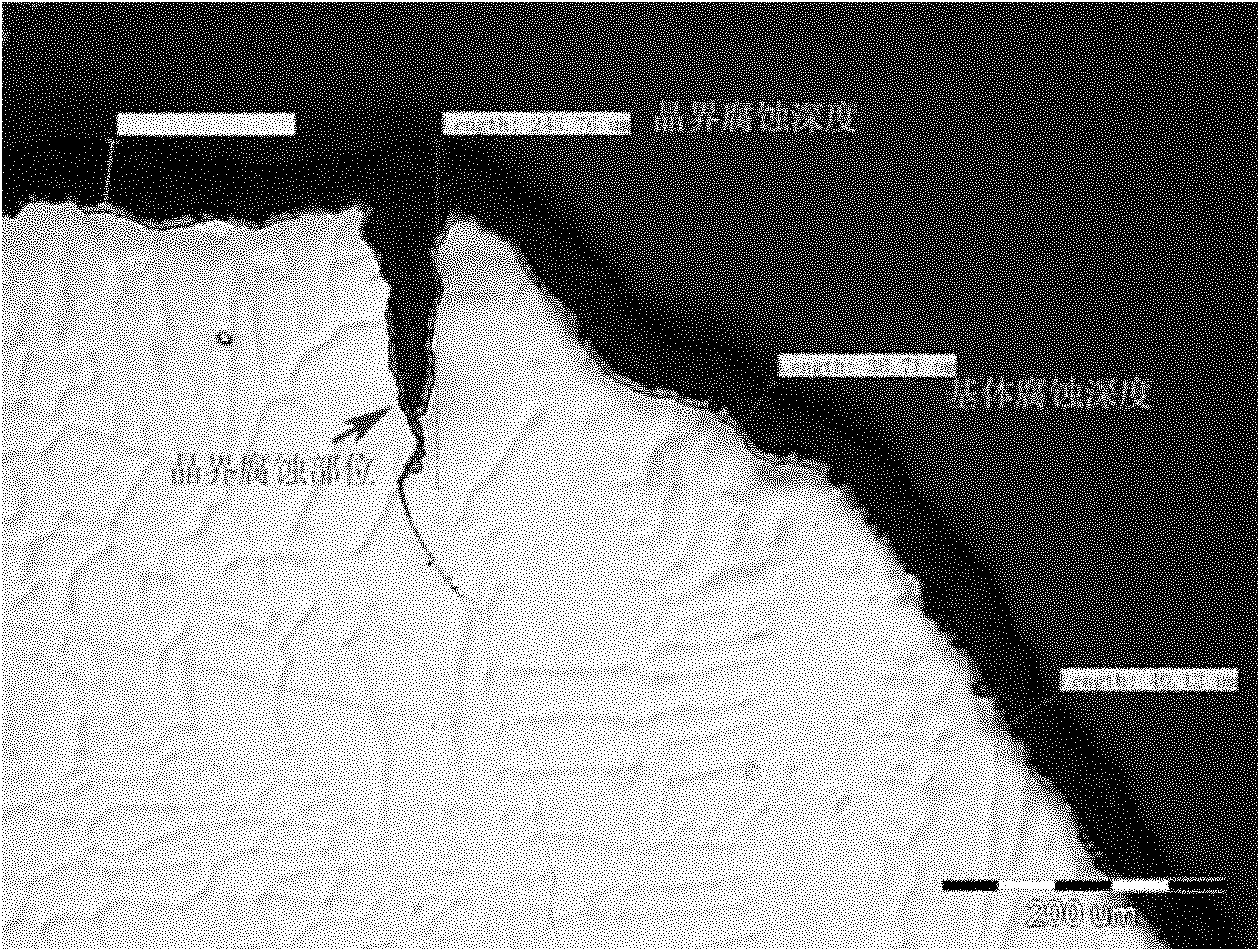

[0032] The corrosion metallographic diagram of the grid prepared in embodiment 1 and 2 is shown in figure 2 , for the definition of corrosion parameters, see image 3 . For the grid manufactured by the method of Example 2, the number of its corroded parts is counted, and the average number of corroded parts of each grid is 3.38; for the grid manufactured according to the method of Example 1, the number of its corroded parts is counted, and the average The number of corroded parts of each plate grid is: 1.42, and its other corrosion parameters are also slightly improved, see Table 1.

[0033] serial number

The number of corrosion parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com