A kind of production method of aluminum foil blank

A production method and technology for aluminum foil blanks, which are applied in the field of non-ferrous metal materials, can solve the problems of poor production process stability, poor stability, and inability to ensure that product performance is always qualified, and achieve enhanced production stability, moderate grain size, and satisfactory processing performance. effect on performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment one: the inventive method produces 0.6mm thick aluminum foil stock

[0047] Step 1: Set the alloy chemical composition ratio as (wt%): Fe=1.0; Si=0.4; Cu=0.03; Mn=0.02; Mg=0.02; Zn=0.08; Cr=0.02; Ti=0.04; balance is Al;

[0048] Step 2: casting and rolling according to the above composition ratio to produce a cast-rolled plate with a thickness of 12 mm;

[0049] Step 3: cold rolling the cast-rolled sheet to 3mm, with a total deformation of 75%;

[0050] Step 4: Perform high-temperature annealing of the cold-rolled sheet at 500°C / 8h;

[0051] Step 5: cold rolling the annealed sheet to 0.6mm, with a total deformation of 80%;

[0052] Step 6: Anneal the 0.6mm thick plate at 390°C / 2.5h.

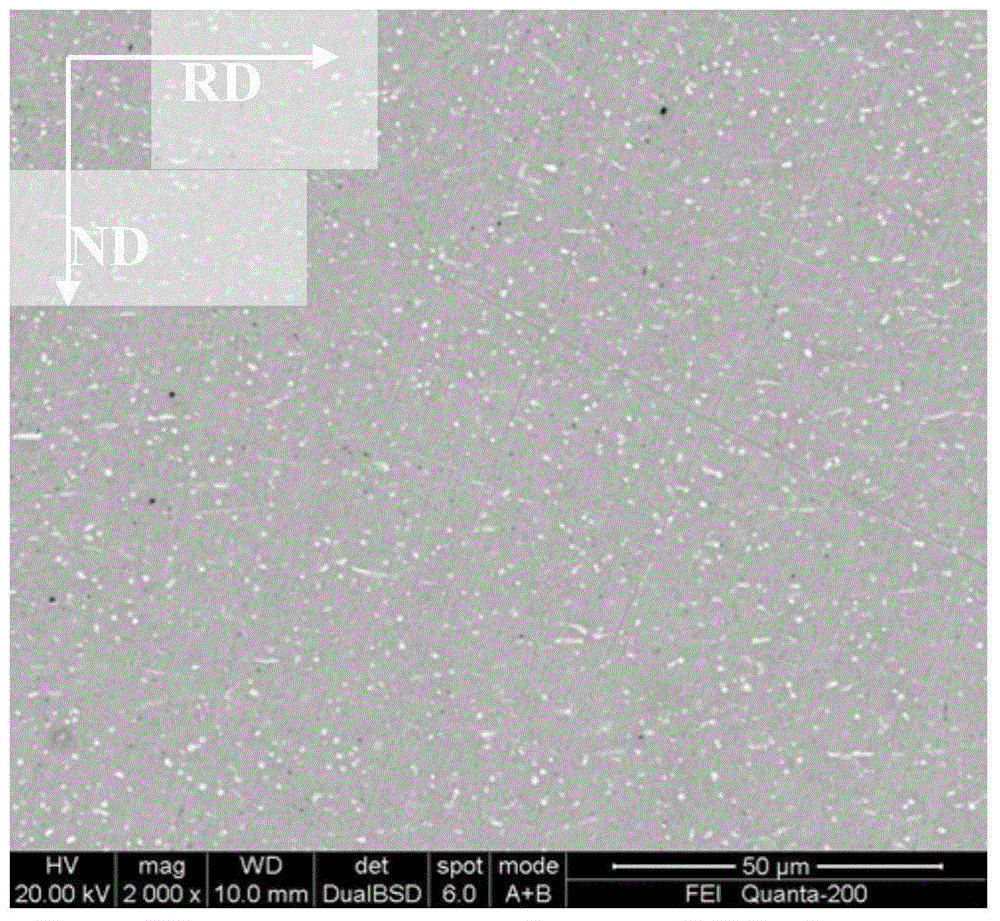

[0053] Carry out SEM detection to the product surface layer after high temperature annealing in step 4, detection result is as follows figure 1 As shown, the test results show that the second phase of the material is dominated by spherical second phase distribution, w...

Embodiment 2

[0056] Embodiment two: the inventive method produces 0.6mm thick aluminum foil stock

[0057] Step 1: Set the chemical composition ratio of the alloy to (wt%): Fe=0.6; Si=0.3; Cu=0.02; Mn=0.03; Mg=0.03; Zn=0.05; Cr=0.03; Ti=0.05; balance is Al;

[0058] Step 2: casting and rolling according to the above composition ratio to produce a cast-rolled plate with a thickness of 6.5 mm;

[0059] Step 3: cold rolling the cast-rolled sheet to 2mm, the total deformation is 69.2%;

[0060] Step 4: Perform high-temperature annealing of the cold-rolled sheet at 510°C / 7h;

[0061] Step 5: cold rolling the annealed sheet to 0.6mm, with a total deformation of 70%;

[0062] Step 6: Anneal the 0.6mm thick plate at 380°C / 3h.

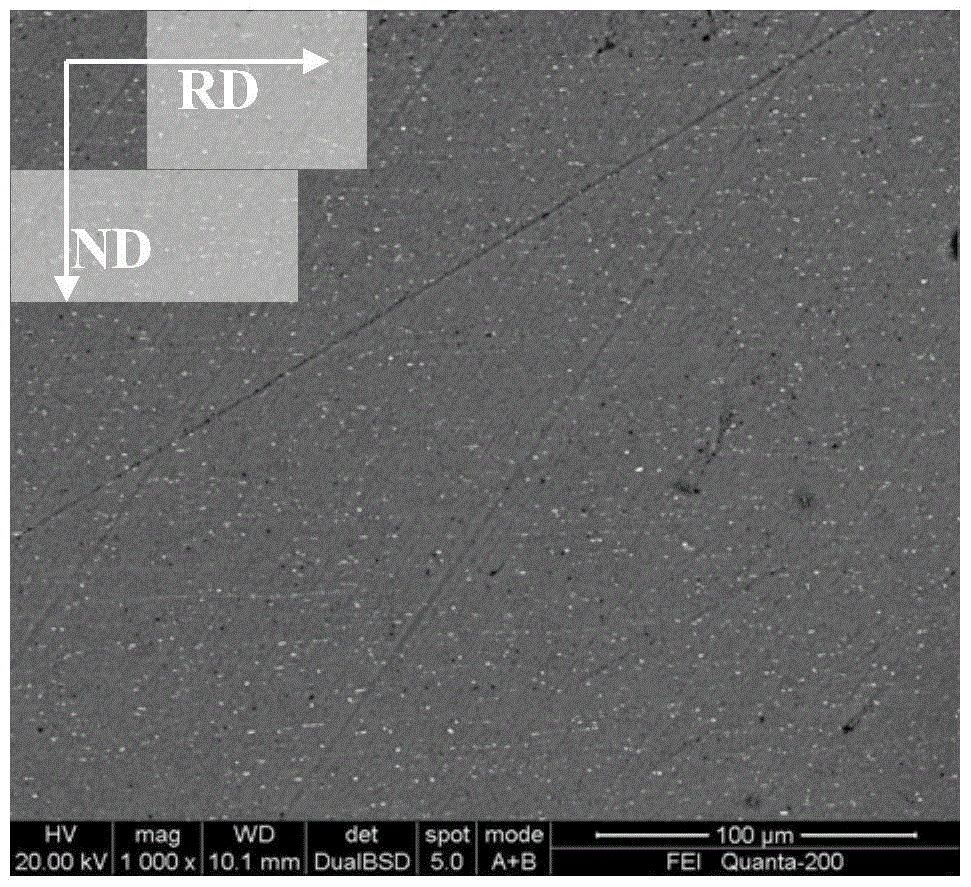

[0063] Carry out SEM detection to the product surface layer after high temperature annealing in step 4, detection result is as follows image 3 The test results show that the interior of the material is dominated by spherical second phase distribution, which is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com