Multi-hole carbon fiber and preparation method thereof

A technology of porous carbon fiber and pore-forming agent, which is applied in fiber processing, fiber chemical characteristics, chemical instruments and methods, etc., can solve the problems of difficult industrialized production, high cost, brittle carbon fiber, etc., and achieves convenient recycling, simple preparation, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

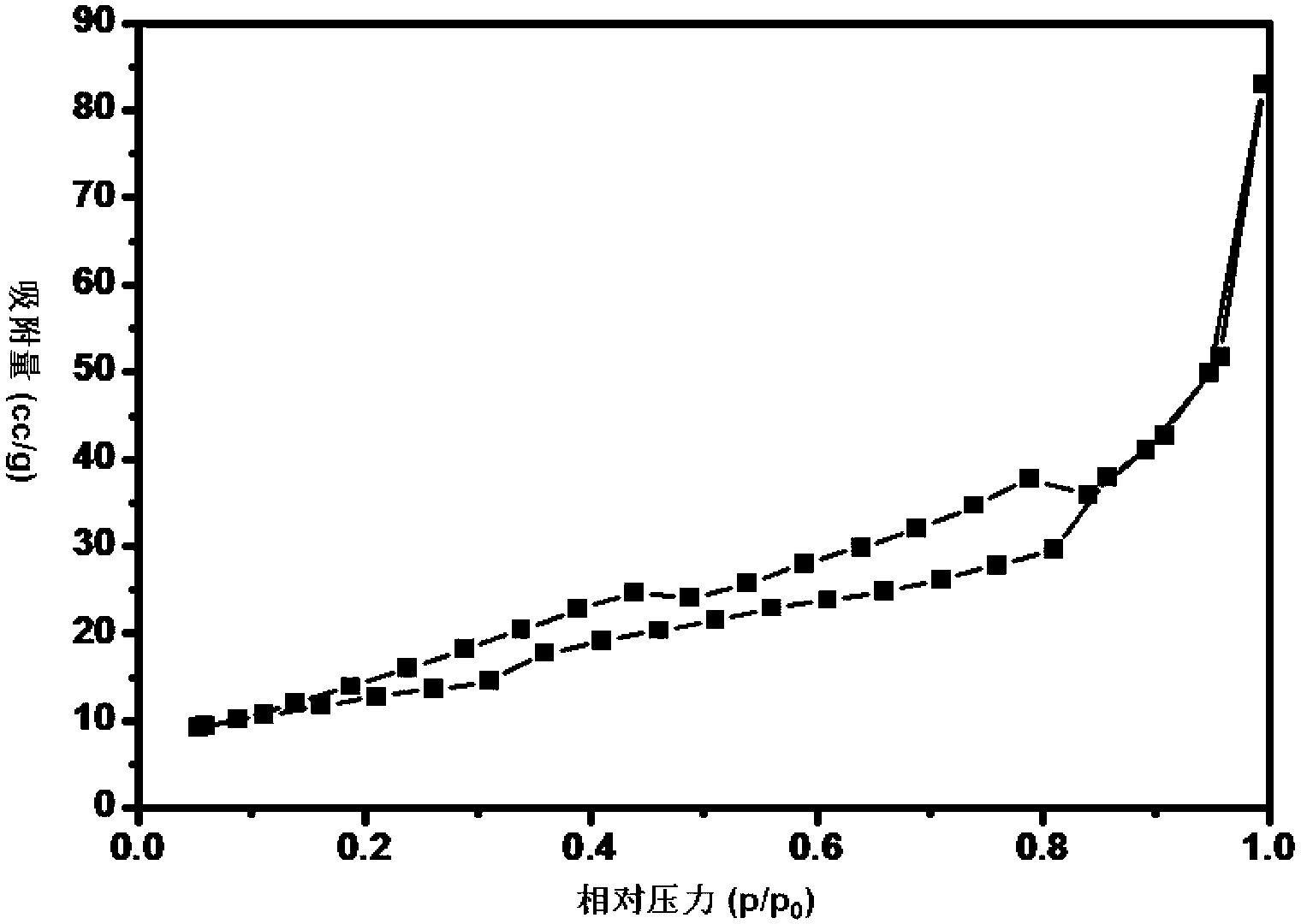

Embodiment 1

[0043] Dissolve 0.1g of pore-forming agent terephthalic acid in 10g of N,N-dimethylformamide. After fully dissolving, add 0.8g of polyacrylonitrile with a number-average molecular weight of 150w, and stir at 80°C for 2 hours to form a uniform and transparent solution.

[0044] The electrospinning process was carried out on a single-nozzle electrospinning device, which consisted of a DC high-voltage power supply, a single capillary spinneret, a collecting plate and a ground wire. The collecting plate was made of aluminum foil, and the electrospinning temperature was 15°C. The specific preparation process is as follows: transfer the prepared precursor solution to a 10mL medical syringe, inject it into the spinneret at a flow rate of 1.0mL / h, apply a high-voltage electric field between the spinneret and the collecting plate to make the spinning liquid After stretching, thinning and solidification, the formed fibers fall on the aluminum foil collecting plate. The working voltage ...

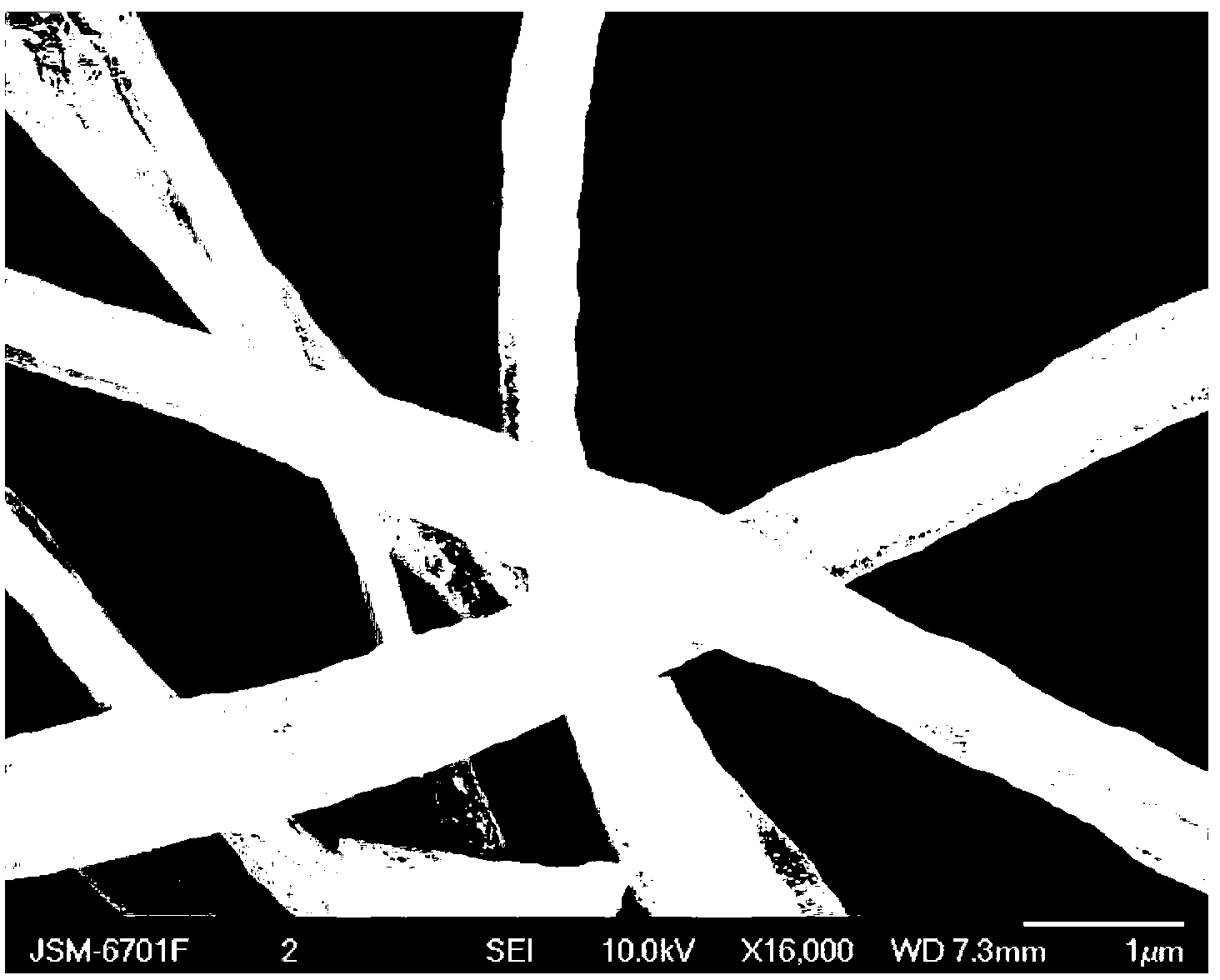

Embodiment 2

[0048] Dissolve 0.3g of terephthalic acid in 10g of N,N-dimethylformamide. After fully dissolving, add 0.8g of polyacrylonitrile with a number average molecular weight of 150w, and stir at 80°C for 2h to form a uniform transparent solution.

[0049] The electrospinning process was carried out on a single-nozzle electrospinning device, as described in Example 1, wherein the collecting plate was aluminum foil, and the electrospinning temperature was 25°C. The specific preparation process is as follows: transfer the prepared precursor solution to a 10mL medical syringe, inject it into the spinneret at a flow rate of 1.0mL / h, apply a high-voltage electric field between the spinneret and the collecting plate to make the spinning liquid After stretching, thinning and solidification, the formed fibers fall on the aluminum foil collecting plate. The working voltage is 30kV, and the distance between the needle tip and the aluminum foil is 15cm. The collected terephthalic acid-polyacry...

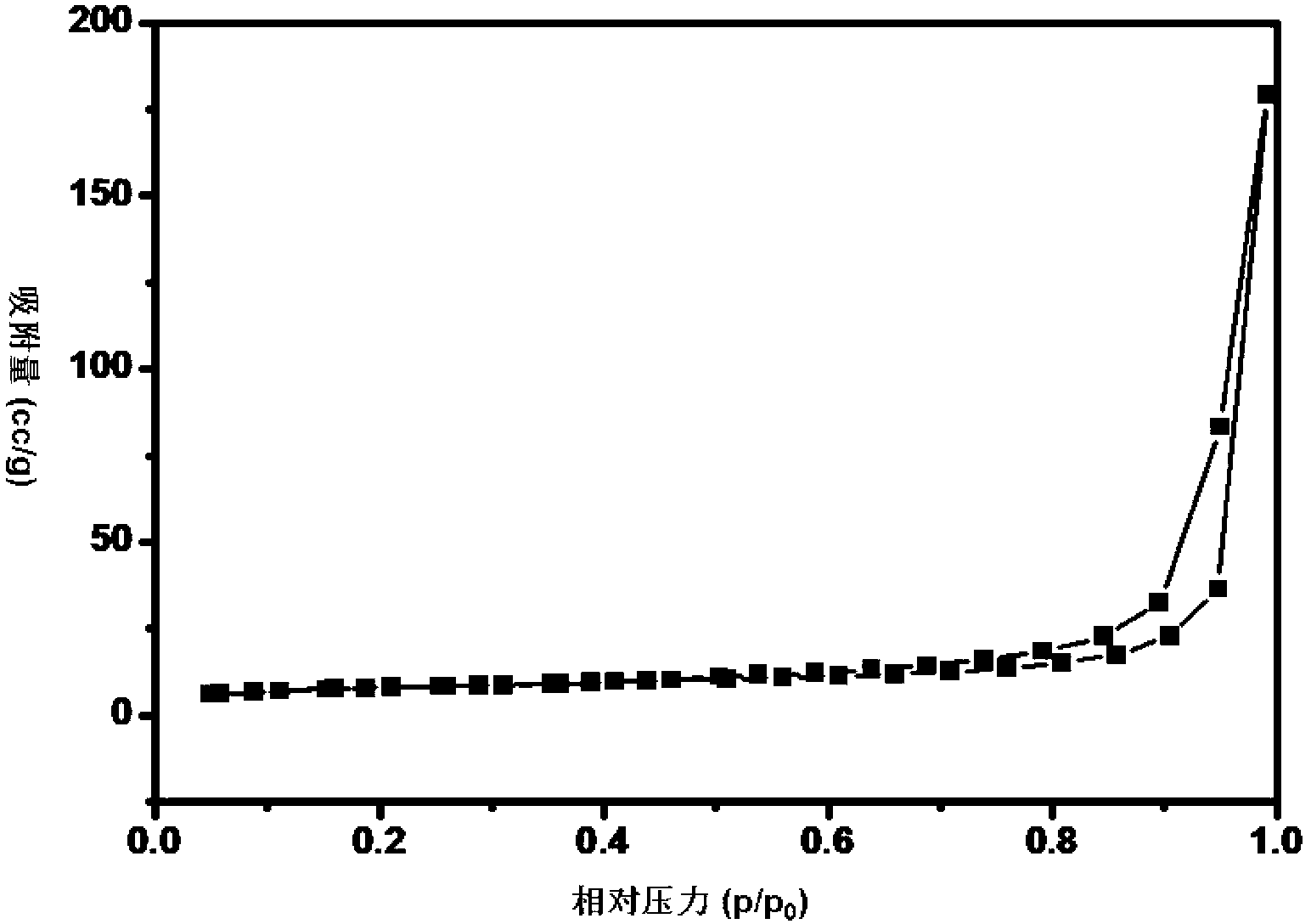

Embodiment 3

[0053] Dissolve 0.5g of terephthalic acid in 10g of N,N-dimethylformamide. After fully dissolving, add 0.8g of polyacrylonitrile with a number average molecular weight of 150w, and stir at 80°C for 2h to form a uniform transparent solution.

[0054] The electrospinning process was carried out on a single-nozzle electrospinning device, as described in Example 1, wherein the collecting plate was aluminum foil, and the electrospinning temperature was 30°C. The specific preparation process is as follows: transfer the prepared precursor solution to a 10mL medical syringe, inject it into the spinneret at a flow rate of 1.0mL / h, apply a high-voltage electric field between the spinneret and the collecting plate to make the spinning liquid After stretching, thinning and solidification, the formed fibers fall on the aluminum foil collecting plate. The working voltage is 30kV, and the distance between the needle tip and the aluminum foil is 15cm. The collected terephthalic acid-polyacry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com