Capsule type snow ice melt inhibiting material, preparation method and application thereof

A technology for inhibiting melting and ice and snow, applied in the field of slow-release ice and snow melting materials and preparation, can solve the problems of large investment, high cost of laying and application, and inability to be widely used, and achieve the effect of no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

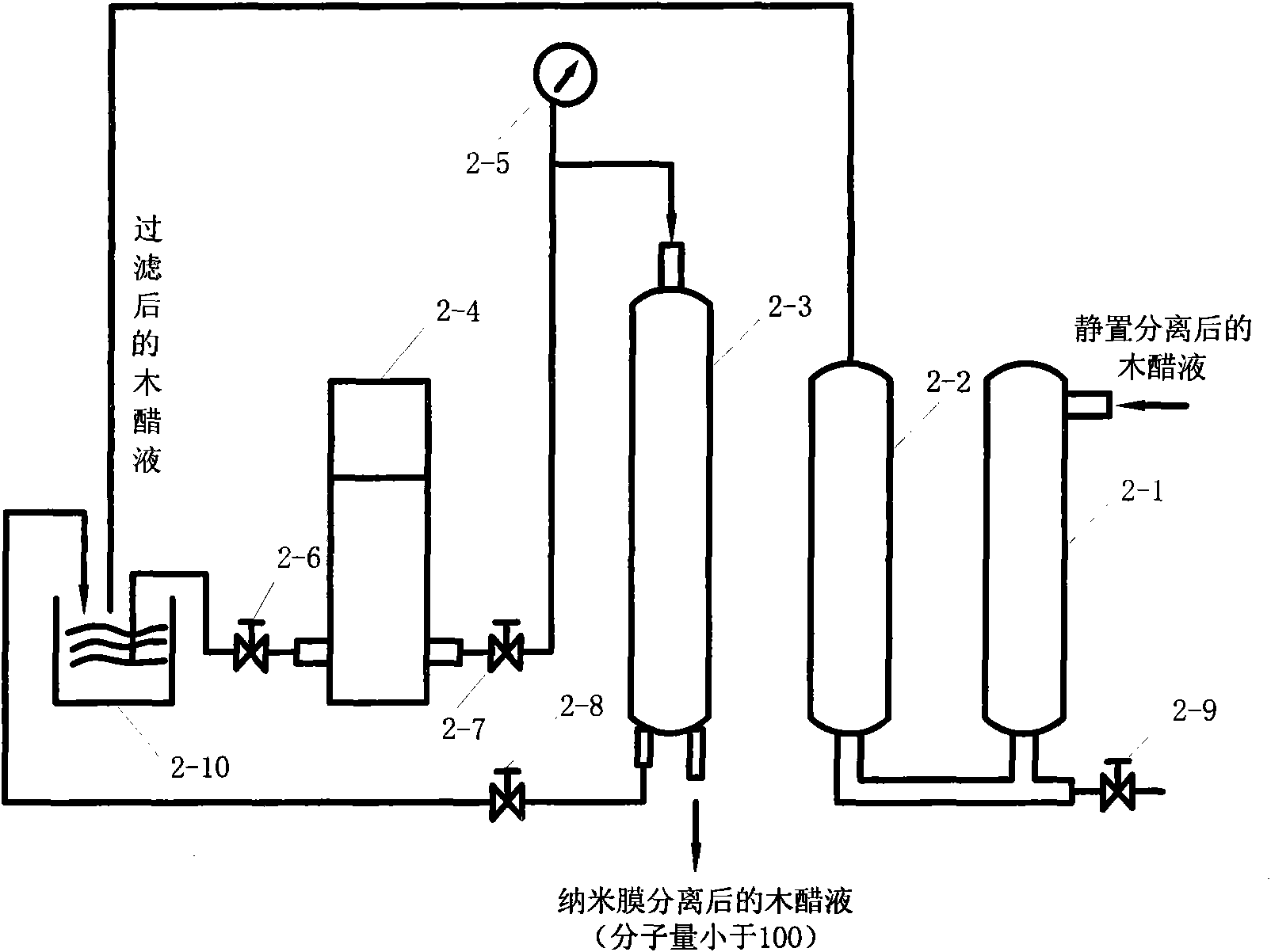

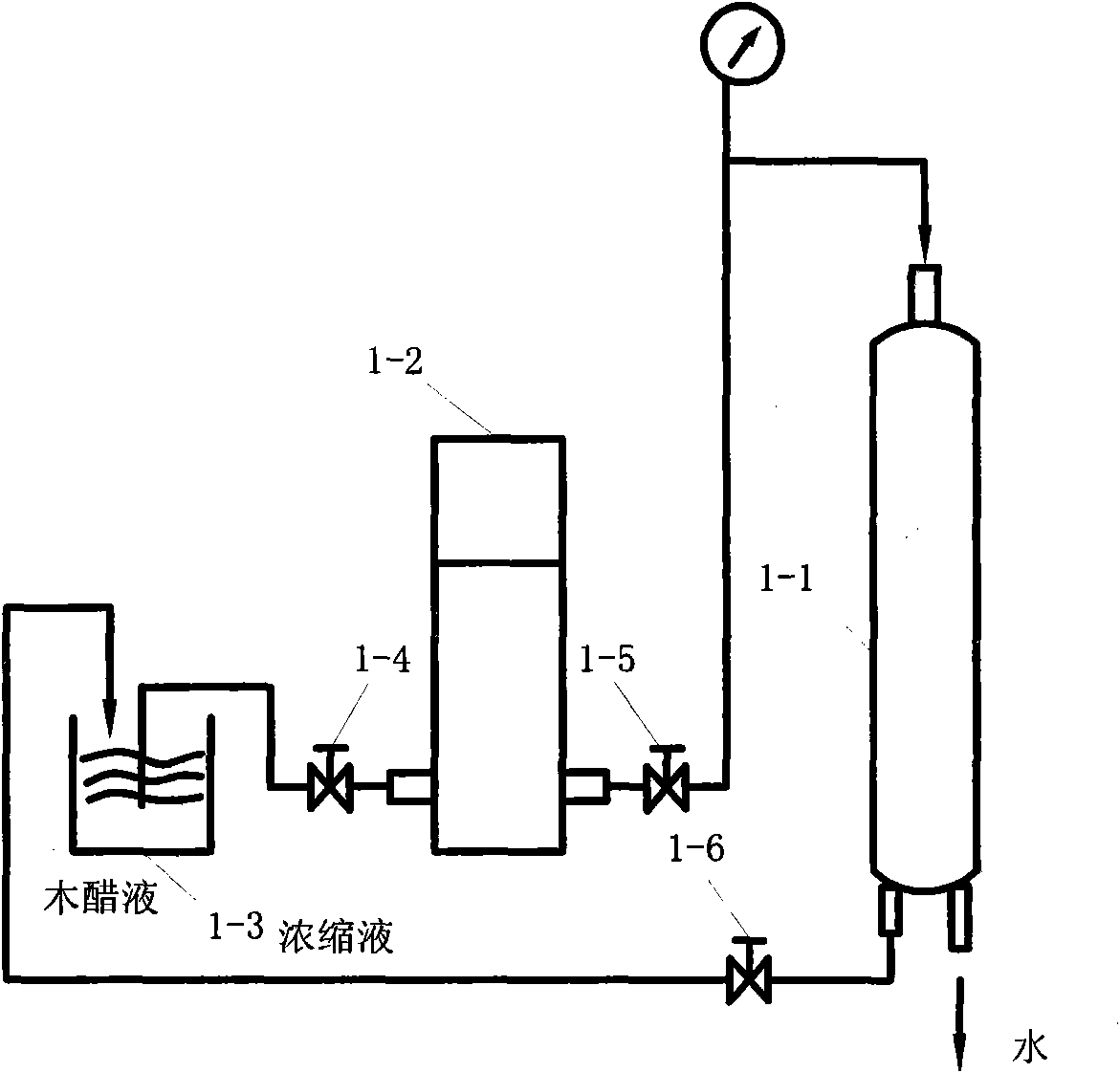

[0041] Embodiment 1: preparation, refining and concentration of wood vinegar

[0042] Preparation of wood vinegar: Add 500 grams of fungus chaff into the retort, conduct retort at a temperature not exceeding 300°C, and cool the discharged gas through a condenser at 90-200°C to collect 145-160 grams Brown-black crude wood acetic acid solution, 140-150 grams of charcoal.

[0043] The crude wood vinegar is still for 1 to 6 months, and the organic phase in the middle is collected after layering, which mainly contains 7.32% acetic acid, 0.85% formic acid, 0.62% propionic acid, 0.15% formaldehyde, 0.25% of furfural, 0.62% of phenol. Phenol is the main reason for the coloration of wood vinegar, so it needs to be decolorized. Put the crude wood vinegar in a container, take copper / lithium composite metal ion as a catalyst, feed air at a temperature of 60 to 80°C and a pressure of 2.7MPa for 5 hours, wherein the catalyst: phenol molar ratio is 1: 2mol, Cu 2+ : Li 2+ =1:3. Phenol i...

Embodiment 2

[0046] Embodiment 2: Preparation of CMA melting ice and snow material

[0047] Preparation of CMA (calcium acetate, magnesium salt) melting ice and snow materials:

[0048] Add 200kg of oxygen calcium, 112kg of oxygen magnesium, and 50kg of water in the reaction kettle, mix well and make a paste, then gradually add 150kg of 20wt% wood vinegar, and control the reaction temperature by controlling the feeding speed of the wood vinegar The temperature does not exceed 70°C; after the reaction is completed, the insoluble matter is removed by filtration, evaporated and concentrated to a solid content of 30 wt%, and dried to obtain a solid CMA snow-melting material.

[0049] The influence of temperature on the reaction; the above reaction temperature is controlled at 50-70°C, and the reaction is easy to control. Under this temperature condition, after 60-100min, the product yield is higher and the performance is better.

[0050] The influence of reactant concentration on product yiel...

Embodiment 3

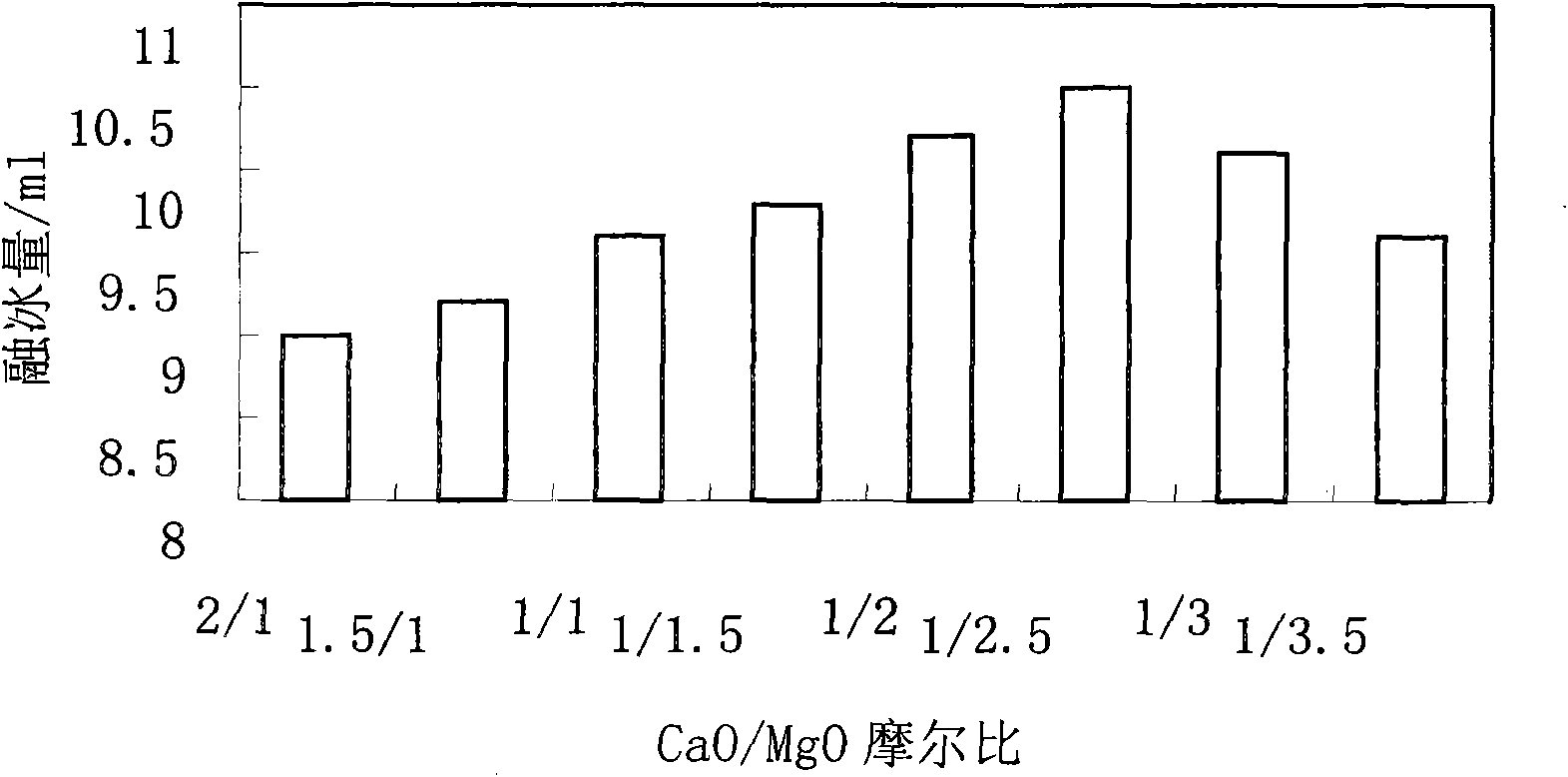

[0052] Example 3: The relationship between the amount of CMA ice and snow melting material and the amount of ice melting

[0053] Put 50ml of water into each of eight 100ml porcelain crucibles, and place them in a thermostat at -10°C for 12 hours to make ice cubes with the same shape. Take CMA deicing agents with different molar ratios, prepare each sample into a saturated solution, then weigh 60ml of deicing agents for each sample, pour them into the ice cubes prepared above, and measure the total amount of liquid after 30 minutes. The results are shown in the table below:

[0054] Table 1. The relationship between snow melting dose and ice melting amount of different molar ratios of CMA

[0055] CaO / MgO

[0056] From the above table 1, image 3 It can be seen that the amount of ice melting varies with the unpredictable CaO / MgO mole, and when the CaO / MgO mole is equal, the amount of ice melting reaches the highest value,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com