Aluminum alloy nickel-free environment-friendly hole sealing agent

A technology of aluminum alloy and sealing agent, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve problems such as difficult adjustment, stable sealing effect, and difficulty in anodic oxidation film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

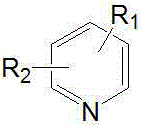

[0071] Embodiment 1, aluminum alloy nickel-free environmental protection sealing agent, the aluminum alloy nickel-free environmental protection sealing agent is an aqueous solution, and also includes 1-20g / L magnesium acetate, 0.01-1g / L sulfonic acid group, mercapto group, Heterocyclic compound of one or several groups in amino group, 5-30g / L complexing agent, 0.01-10g / L pH buffering agent.

Embodiment approach 2

[0072] Embodiment 2 is the same as Embodiment 1, and the heterocyclic compound is a nitrogen heterocyclic compound.

Embodiment approach 3

[0073] Embodiment 3 is the same as Embodiment 1 or 2, and the heterocyclic compound is a six-membered heterocyclic compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com