Multilevel porous molecular sieve catalyst as well as preparation method and application thereof

A molecular sieve and catalyst technology, which is applied to the multi-stage porous molecular sieve catalyst and the fields of preparation and application, can solve the problems of poor product selectivity, low catalyst space velocity and low conversion rate, and achieve high activity, high product selectivity and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

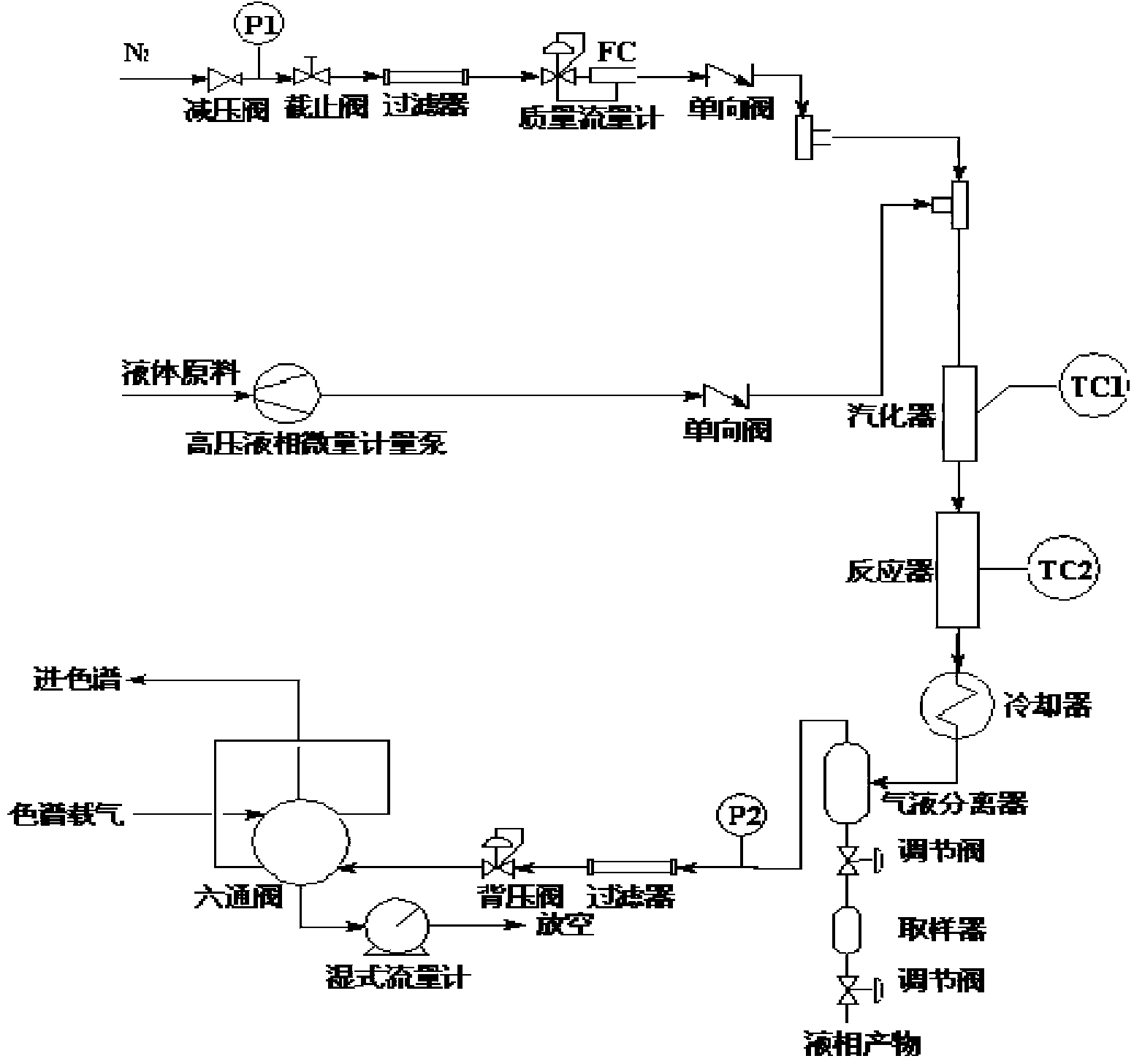

Method used

Image

Examples

Embodiment 1

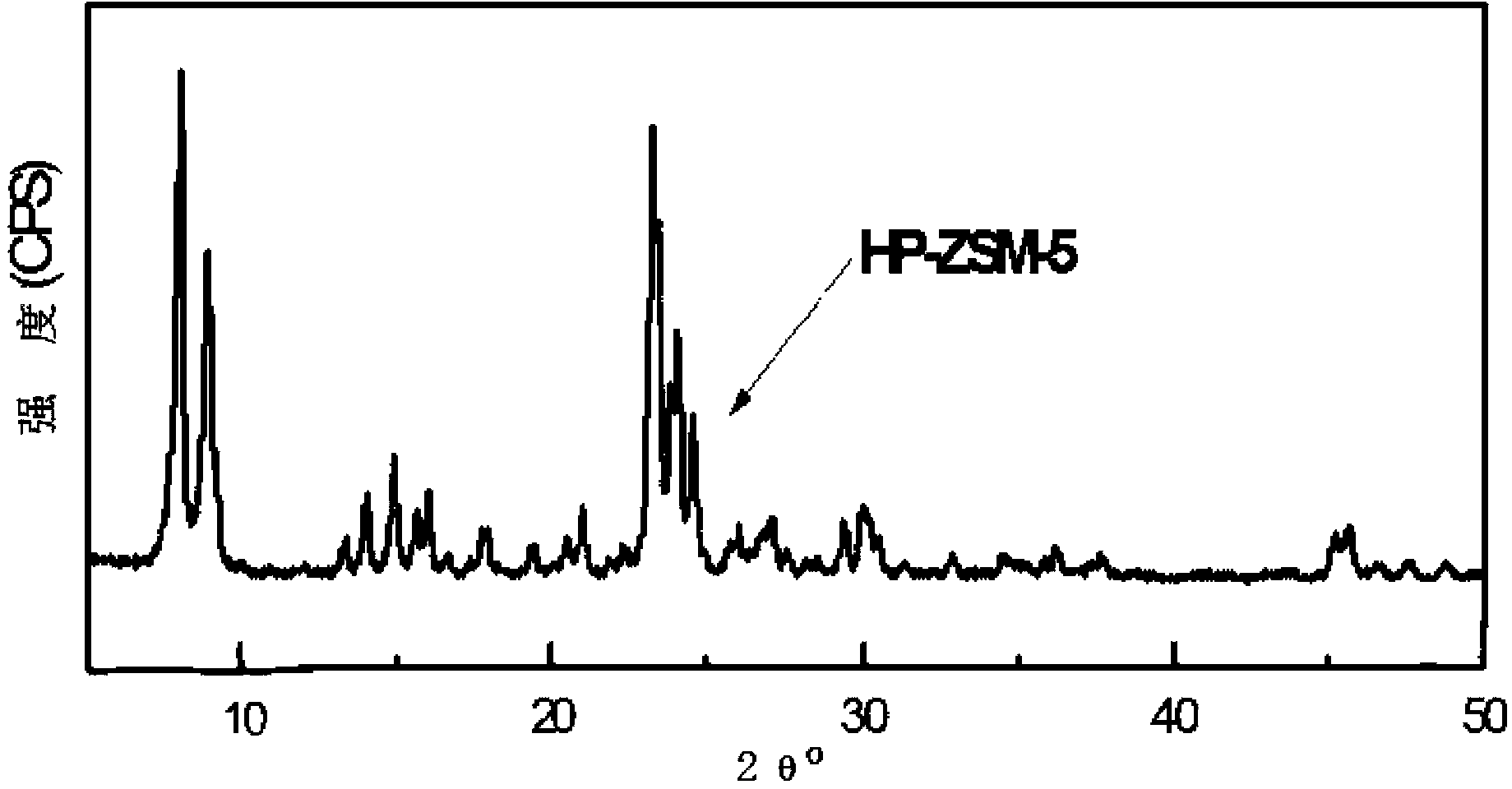

[0041] In the first step, silicon source: tetraethyl orthosilicate (TEOS), aluminum source: aluminum tert-butoxide, organic template agent: tetrapropylammonium hydroxide (TBAOH), and mesoporous directing agent (HTS) are mixed. SiO 2 :Al 2 o 3 :TPAOH:HTS=50-180:1:0.3:0.01-0.05, the solvent used is ethanol. In the second step, 9 g of water and 1 g of TPAOH were added. The crystallization time is 3 days, and the temperature is 180° C., and the method obtains ZSM-5 zeolite with a multi-level pore structure.

Embodiment 2

[0043] In the first step, the silicon source, aluminum source, and TPAOH were mixed uniformly in ethanol and dried into a xerogel, and then the ethanol solution of HTS was mixed with it and dried in air to form SiO 2 :Al 2 o 3 :TPAOH:HTS=50-180:1:0.3:0.01-0.05, xerogel. In the second step, 9 g of water and 1 g of TPAOH were added. The crystallization time is 3 days, and the temperature is 180° C., and the method obtains ZSM-5 zeolite with a multi-level pore structure.

Embodiment 3

[0045] Weigh 7g of ordinary ZSM-5 molecular sieve purchased from Nanhua Catalyst Factory, add γ-Al 2 o 3 3g, after mixing evenly, add 4% dilute nitric acid for kneading, extrusion molding, put it into a constant temperature drying oven at 120°C and dry for 12 hours, then roast and crush the strip-shaped catalyst to 20-40 mesh particles, and finally roast Catalyst A is then obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com