Preparation method of efficient adsorbent porous magnesium oxide

A porous magnesium oxide, adsorbent technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problem of not reaching drinking water, low adsorption efficiency, and difficult to meet continuous operations And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

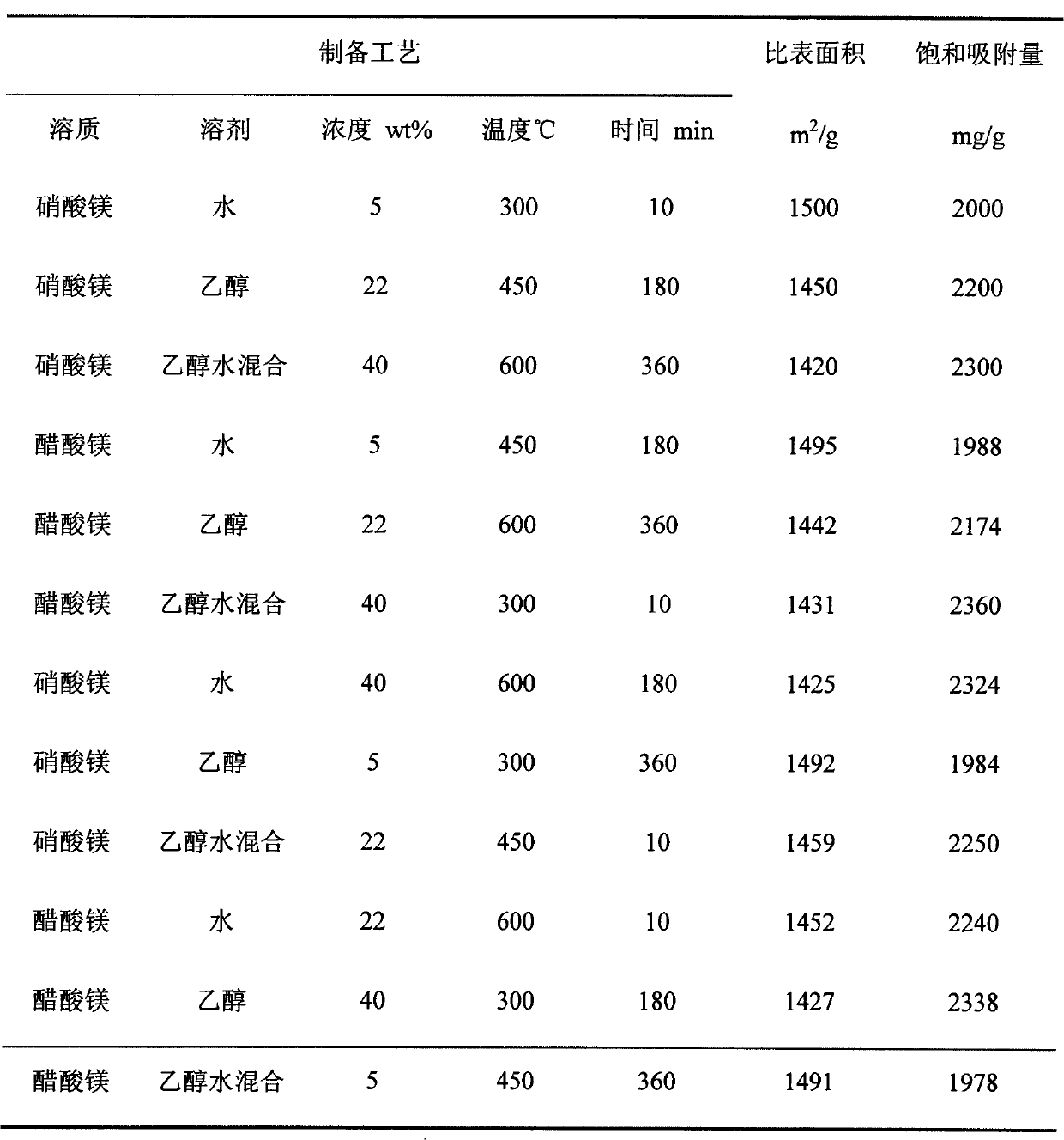

[0013] The active carbon is soaked in water, ethanol or ethanol-water mixed solution with a concentration of 5wt%, 22wt%, and 40wt% magnesium nitrate and magnesium acetate respectively, stirred for 5 hours, filtered, dried, and calcined under a protective atmosphere. The calcining temperature is 300 ° C, At 450°C and 600°C, the calcination time is 10min, 180min, and 360min, respectively. The specific surface area and saturated adsorption capacity for lead ions of the samples obtained from the orthogonal experiments of each process are tested, as shown in Table 1.

[0014] Table 1 Specific surface area of porous magnesium oxide and saturated adsorption capacity for lead ions

[0015]

Embodiment 2

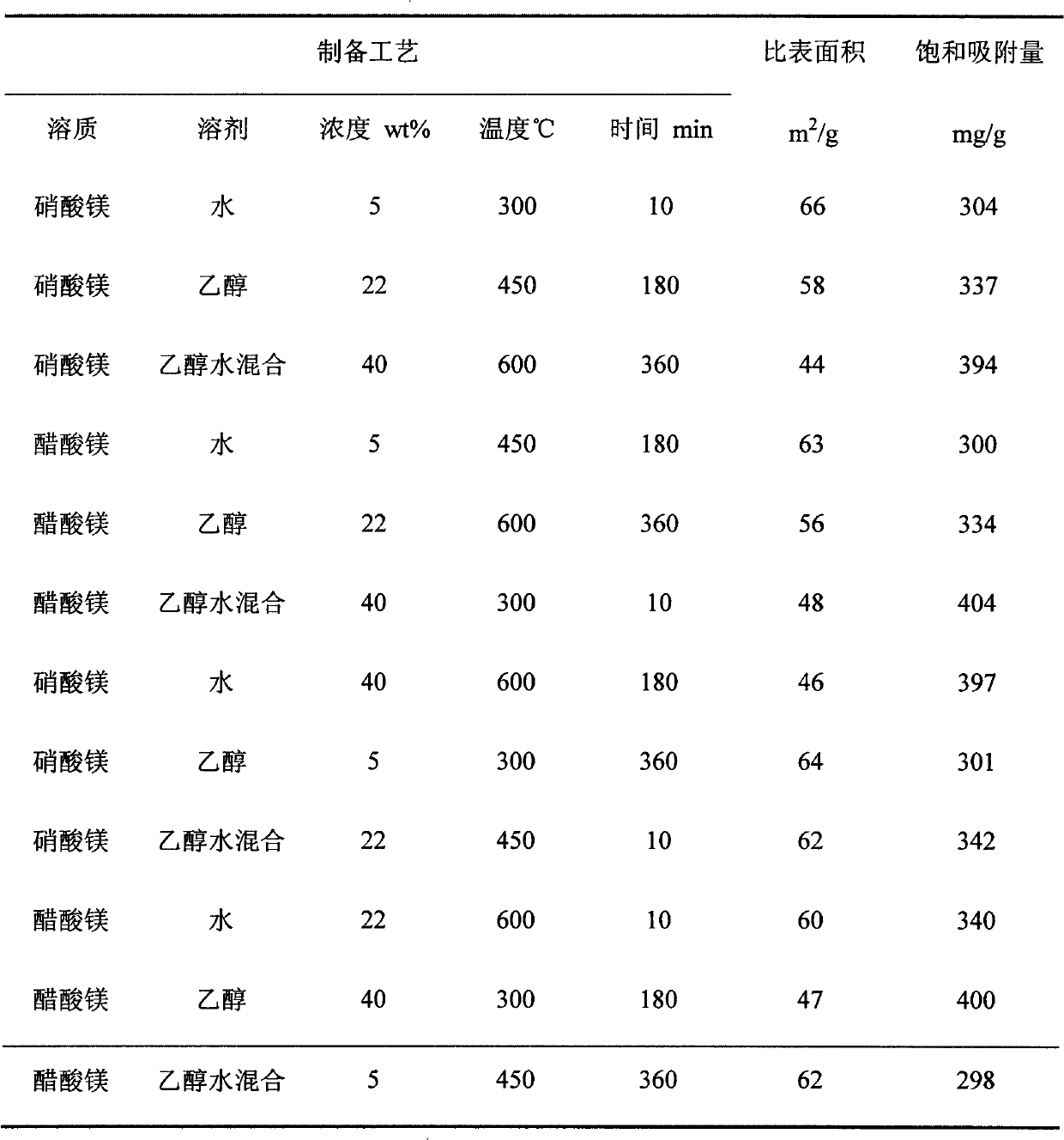

[0017] Diatomaceous earth is soaked in water, ethanol or ethanol-water mixed solutions with concentrations of 5wt%, 22wt%, and 40wt% magnesium nitrate and magnesium acetate respectively, stirred for 5 hours, filtered, dried, and calcined in a protective atmosphere at a temperature of 300°C , 450°C, 600°C, the calcination time is 10min, 180min, 360min respectively. The specific surface area and saturated adsorption capacity for lead ions of the samples obtained from the orthogonal experiments of each process are tested, as shown in Table 2.

[0018] Table 2 Specific surface area of porous magnesium oxide and saturated adsorption capacity for lead ions

[0019]

Embodiment 3

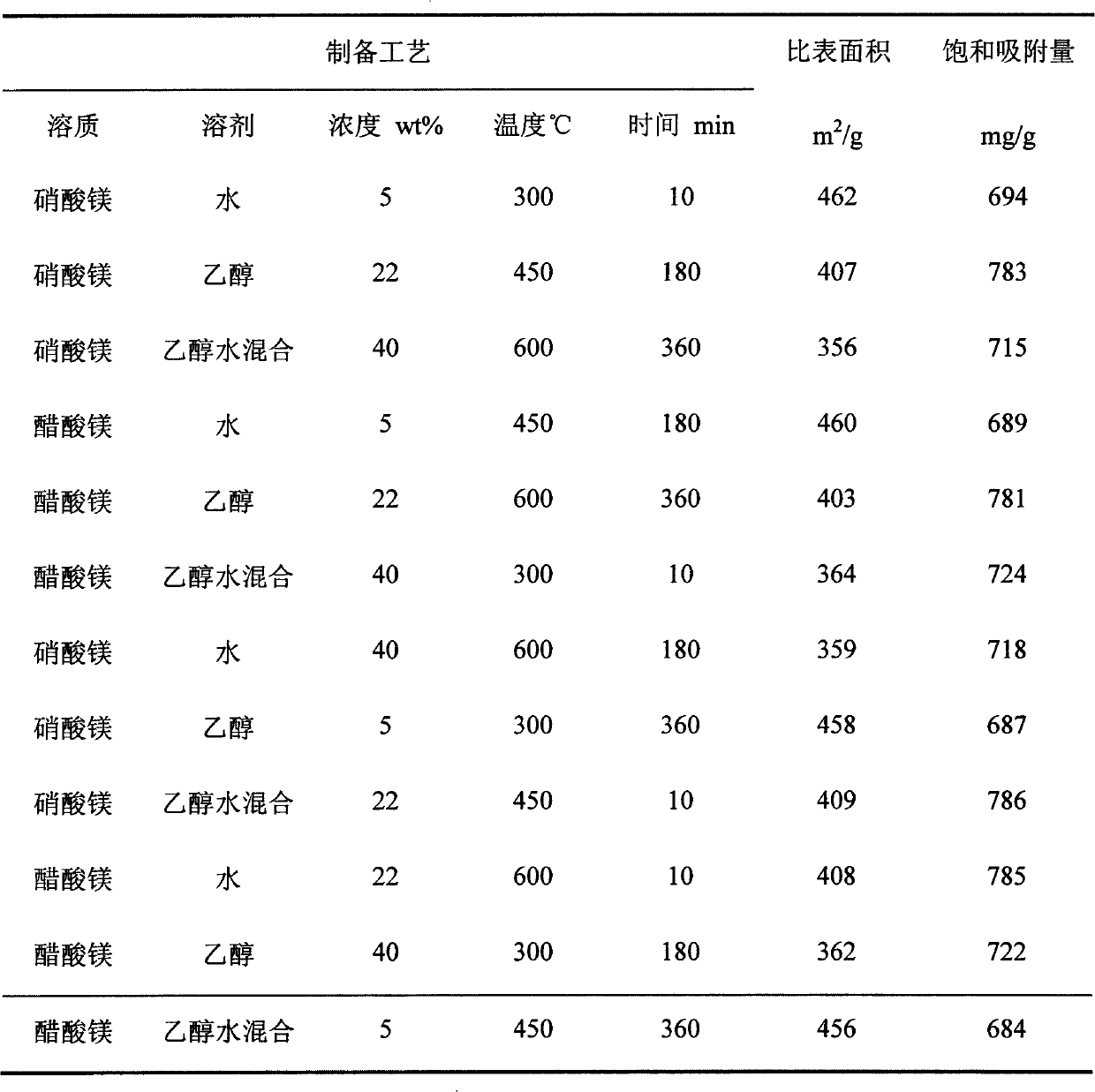

[0021] Soak the silica gel in water, ethanol or ethanol-water mixed solutions with a concentration of 5wt%, 22wt%, and 40wt% magnesium nitrate and magnesium acetate, stir for 5 hours, filter, dry, and calcinate in a protective atmosphere at 300°C and 450°C respectively. ℃, 600 ℃, the calcination time is 10min, 180min, 360min respectively. The specific surface area and saturated adsorption capacity for lead ions of the samples obtained from the orthogonal experiments of each process are tested, as shown in Table 3.

[0022] Table 3 Specific surface area of porous magnesium oxide and saturated adsorption capacity for lead ions

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com