Multi-stage segmental ore-dressing, purifying, and comprehensive utilization method for low-grade magnesite

A magnesite, low-grade technology, applied in recycling technology, chemical instruments and methods, wet separation, etc., can solve the problem that low-grade magnesite is not effectively utilized, high-grade magnesite resources are reduced, and it is difficult to meet Market demand and other issues, to achieve the effects of cheap raw materials, low production costs, and high output rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

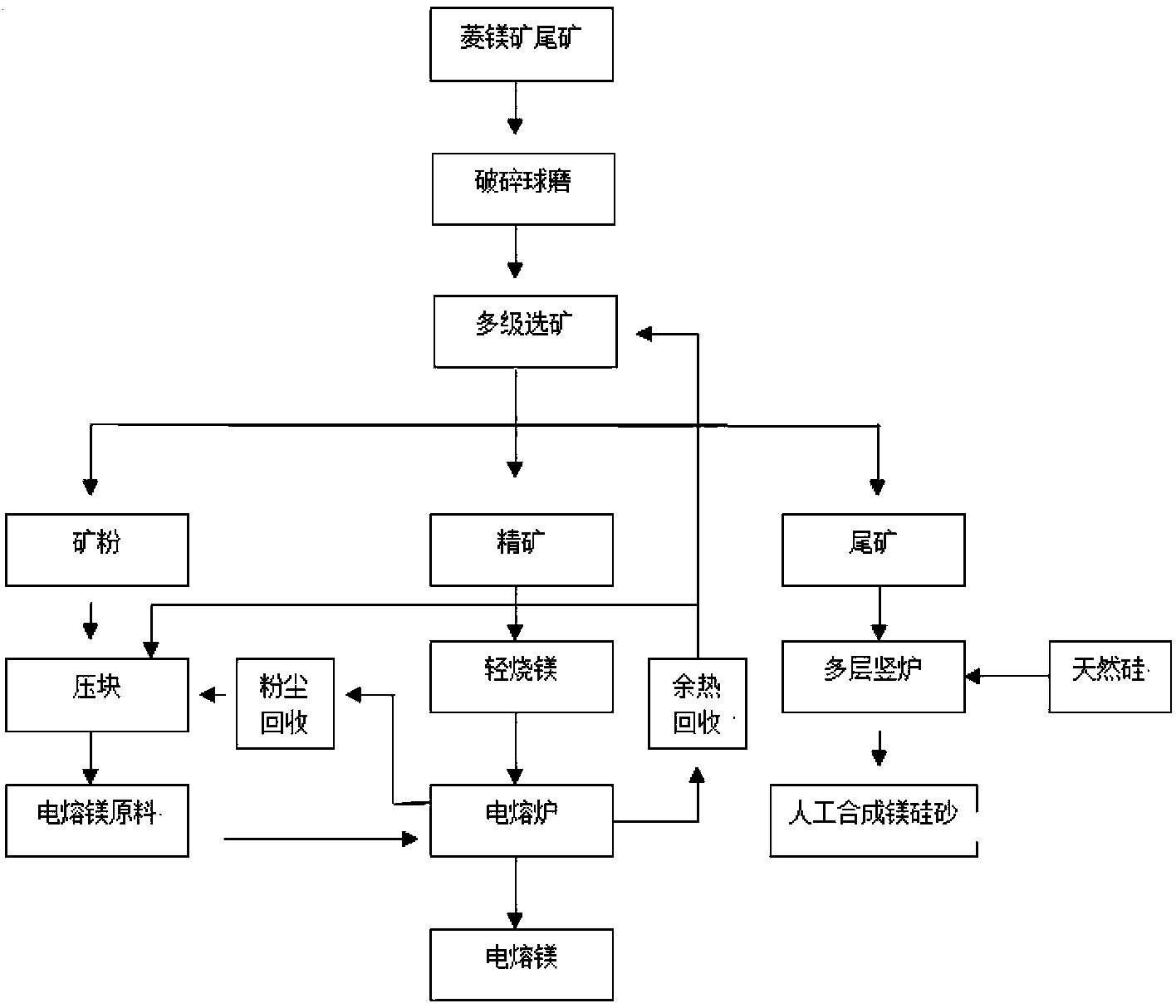

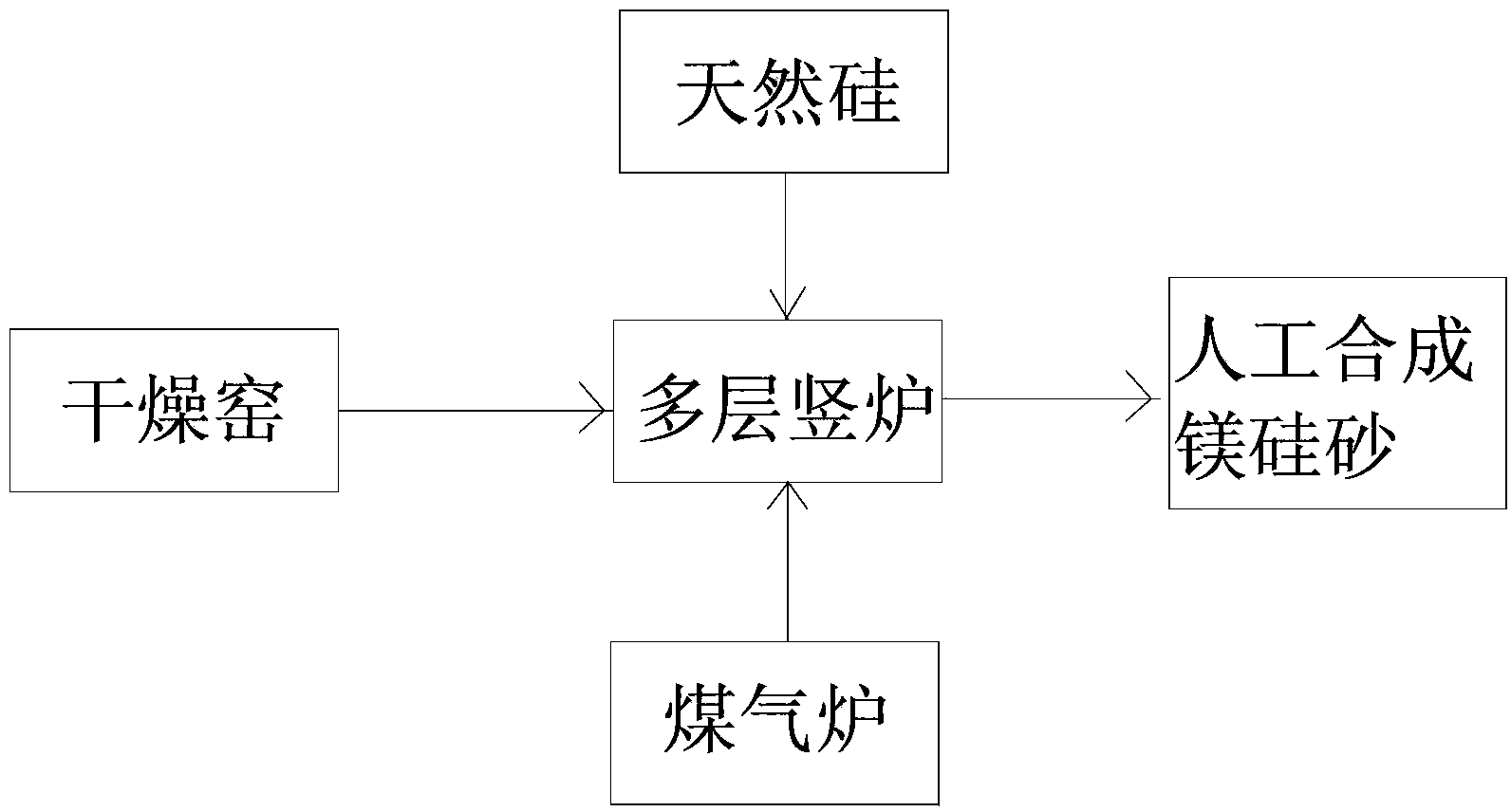

[0030] After the magnesite tailings raw ore is crushed and screened, the ore below -60mm enters the production system, and through grinding and classification, -0.074μm reaches (70-80)%, enters the flotation system, adds flotation combination reagents, and passes through the first stage , secondary and tertiary flotation to obtain qualified magnesite concentrate.

[0031] Flotation reagents: cocamine, oxidized paraffin soap, terpineol oil, the addition amount is: cocamine reagent: 200-260g / t; oxidized paraffin soap reagent: 300-500 g / t; terpineol oil reagent: 50 -150g / t; Concentrate powder with MgO grade > 47% in mineral processing products is mixed with recovered magnesium oxide powder and rolled according to the specified time, the particle size is between 20-80mm, the raw materials are fully mixed, and the raw materials are preliminarily compacted , the compacted material is fed into the roller compactor through the belt conveyor for primary compaction, transported by the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com