Mineral additives and production of lightweight composite materials from carbonatable calcium silicate

A composite material, calcium silicate technology, used in cement production, carbon capture, ceramic products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

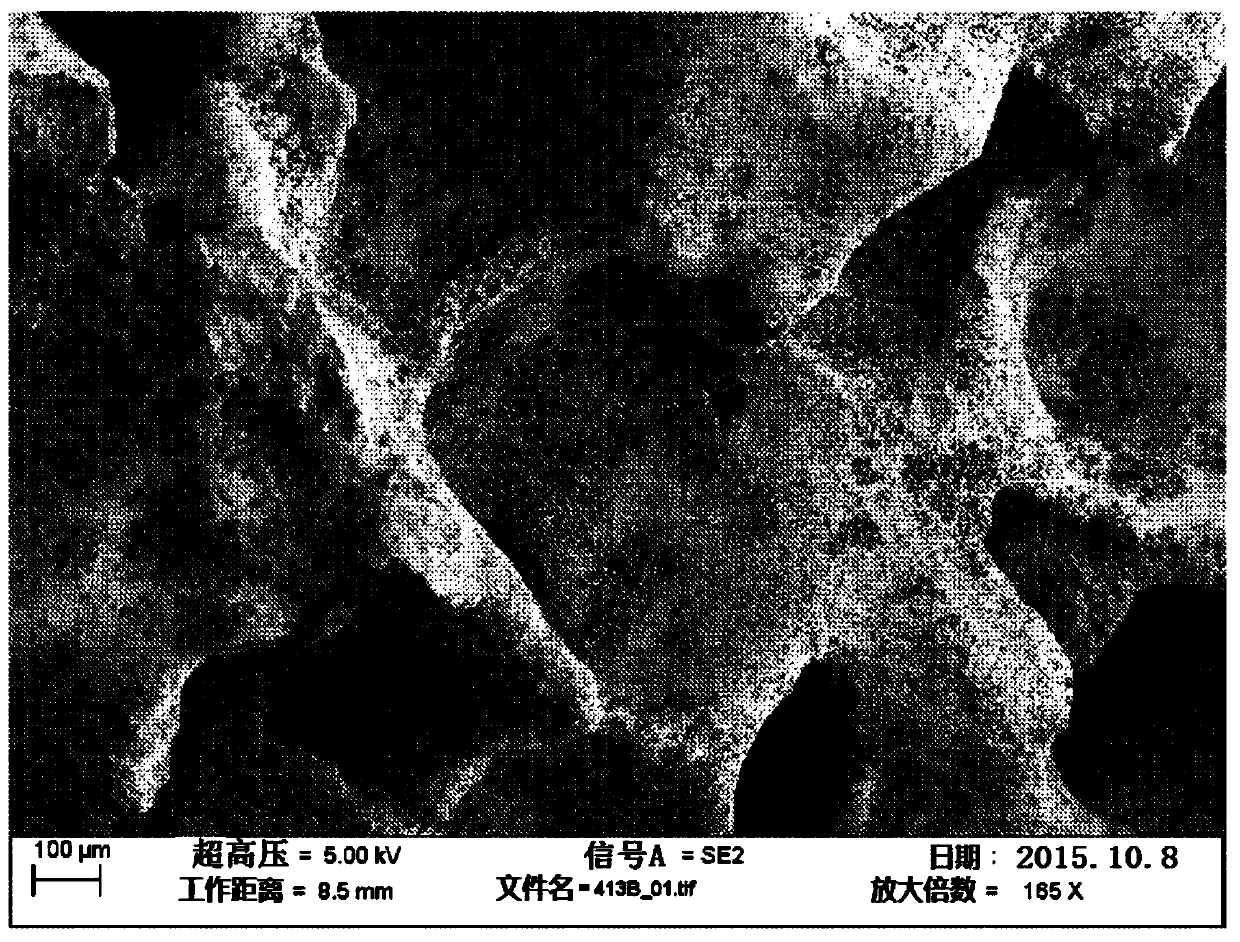

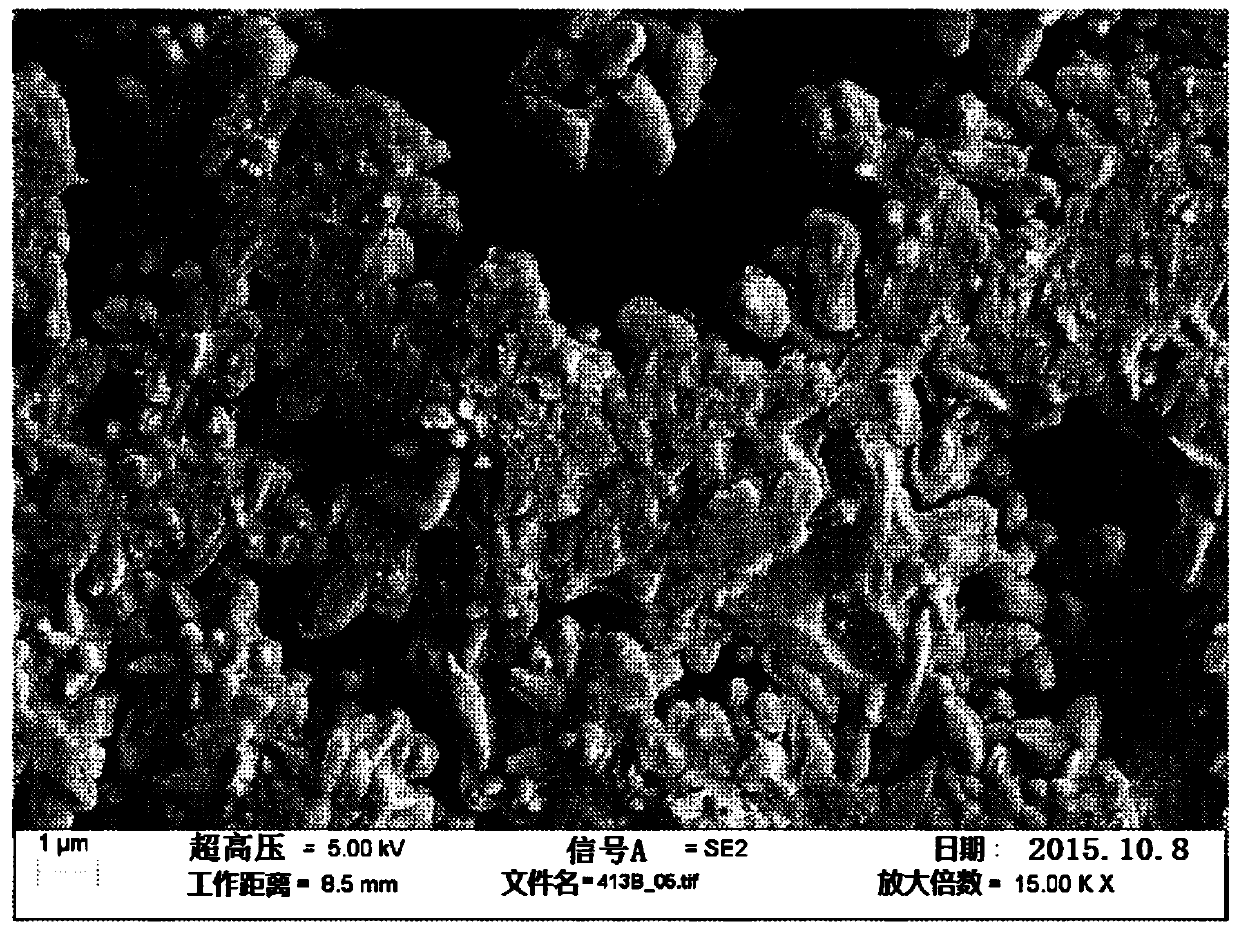

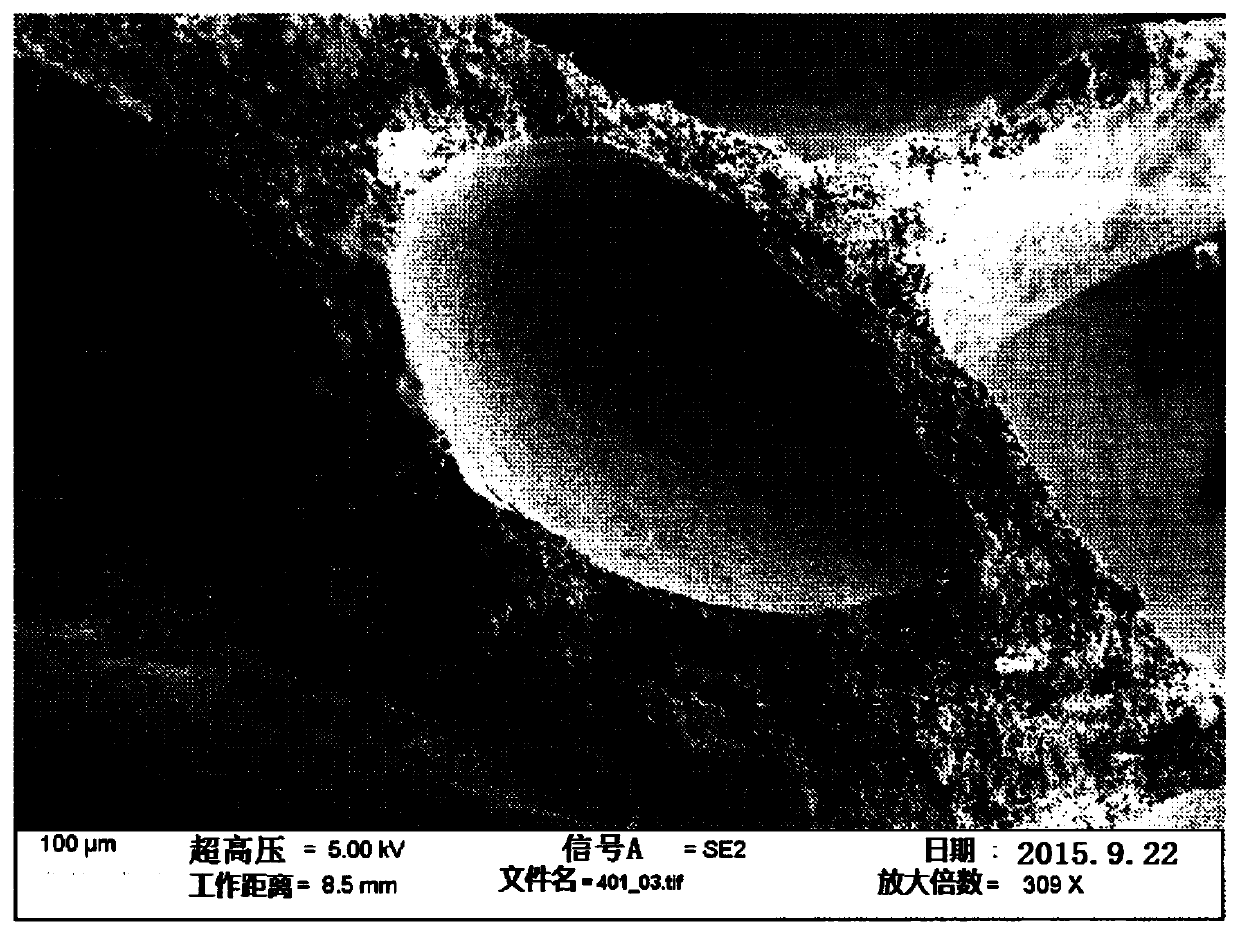

[0090] Use 92.5wt% (solid) of Pecs, 7.5wt% (solid) of CaO and 0.13% (solid) of Al powder, 15% (of the addition of Al) surfactant to prepare water-based slurry, As-cast slurry can form foam by itself. These slurries can be prepared with or without superplasticizers / dispersants, with W / S ratios ranging from 0.35 to 0.70 or higher. The CO2-cured, gas-entrained samples of this example showed calcite as the predominant carbonation phase, with no aragonite, as analyzed by X-ray diffraction (XRD). These samples achieved compressive strengths ranging from approximately 0.2 to 1.9 MPa and densities ranging from 450 to 540 kg / m 3 .

Embodiment 2

[0092] Using 1.67wt% (solid) of magnesium acetate tetrahydrate, 90.83wt% (solid) of Pecs and 7.5% (solid) of CaO and 0.143% (solid) of Al powder, 20% (the addition of Al ) surfactant to prepare water-based slurry, and the cast slurry can form foam by itself. These slurries can be prepared with or without superplasticizers / dispersants, with W / S ratios ranging from 0.4 to 0.60 or higher. The CO2-solidified, gas-entrained samples in this example showed aragonite whiskers or needles as their primary carbonation phase and calcite as their secondary carbonation phase by X-ray diffraction (XRD) analysis. These samples achieved compressive strengths ranging from approximately 1.6 to 3.1 MPa and densities ranging from 480 to 490 kg / m 3 .

Embodiment 3

[0094] Use 10wt% (solid) of submicron high activity magnesia, 86wt% (solid) of Pecs and 4% (solid) of CaO and 0.143% (solid) of Al powder, 20% (the addition of Al ) surfactant to prepare water-based slurry, and the cast slurry can form foam by itself. These slurries can be prepared with or without superplasticizers / dispersants, with W / S ratios ranging from 0.4 to 0.60 or higher. The CO2-solidified, gas-entrained samples in this example showed aragonite and dolomite as the major carbonation phases, and calcite as the minor carbonation phase, as analyzed by X-ray diffraction (XRD). These samples achieved a compressive strength of about 2.5MPa and a density range of 460±4kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com