Preparation method of one-dimensional basic magnesium carbonate nano wire and porous magnesium oxide nano wire

A technology of nano-magnesium carbonate and porous magnesia, which is applied in magnesium oxide, magnesium carbonate, nanotechnology and other directions to achieve the effects of good crystallinity, high purity, specific surface area and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Add 20.3g of magnesium chloride hexahydrate, 24g of urea and 250ml of water into a 500ml conical flask with stopper, place it in an oven and heat to 100 oC, react for 12 hours to obtain a precipitate;

[0025] (2) Suction and filter the precipitate, and repeatedly wash with water until there is no impurity ion to obtain a filter cake;

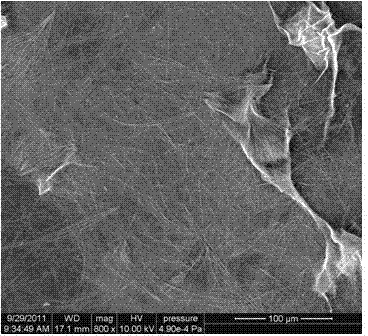

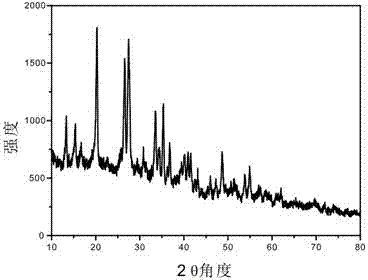

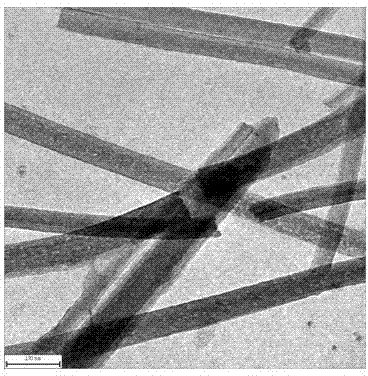

[0026] (3) Place the filter cake in an oven and dry it at 80 oC for 4 hours to obtain one-dimensional basic magnesium carbonate nanowires with a diameter of 50-250 nanometers and a length of about 10-500 microns;

[0027] (4) Place the one-dimensional basic magnesium carbonate nanowires in a muffle furnace and heat to 400oC for 1 hour in an air atmosphere to obtain one-dimensional porous magnesium oxide nanowires.

[0028]

Embodiment 2

[0030] (1) Add 4.06g of magnesium chloride hexahydrate, 2.4g of urea and 100ml of water into a 125ml polytetrafluoroethylene reactor, place it in an oven and heat to 100oC, react for 9 hours to obtain a precipitate;

[0031] (2) Suction and filter the precipitate, and repeatedly wash with water until there is no impurity ion to obtain a filter cake;

[0032] (3) Place the filter cake in an oven and dry it at 80 oC for 4 hours to obtain one-dimensional basic magnesium carbonate nanowires with a diameter of 50-250 nanometers and a length of about 10-500 microns;

[0033] (4) Place the one-dimensional basic magnesium carbonate nanowires in a muffle furnace and heat to 400oC for 1 hour in an argon atmosphere to obtain one-dimensional porous magnesium oxide nanowires.

Embodiment 3

[0035] (1) Add 12.04 g of magnesium sulfate, 24 g of urea and 250 ml of water to a 500 ml conical flask with stopper, place it in an oven and heat to 100 oC, react for 12 hours to obtain a precipitate;

[0036] (2) Suction and filter the precipitate, and repeatedly wash with water until there is no impurity ion to obtain a filter cake;

[0037] (3) Place the filter cake in an oven and dry it at 80 oC for 4 hours to obtain one-dimensional basic magnesium carbonate nanowires with a diameter of 50-250 nanometers and a length of about 10-200 microns;

[0038] (4) Place the one-dimensional basic magnesium carbonate nanowires in a muffle furnace, heat it to 500oC in an air atmosphere and calcinate for 1 hour to obtain one-dimensional porous magnesium oxide nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com