Developer for electrostatic latent image development and image forming method

An electrostatic latent image, positively charged technology, applied in the direction of developer, electric recording process using charge pattern, equipment for electric recording process using charge pattern, etc., can solve the problem of the reduction of toner charge and the scattering of toner , fog and other problems, to achieve the effect of suppressing toner scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0021] A first embodiment of the present invention relates to a developer for developing a positively charged electrostatic latent image (hereinafter also referred to as a developer). The developer for developing a positively chargeable electrostatic latent image according to the first embodiment is a developer for developing a positively chargeable electrostatic latent image used in an image forming apparatus including a latent image bearing portion and a cleaning portion, wherein the latent image The carrier part has at least a photosensitive layer made of amorphous silicon formed on the conductive substrate, the cleaning part has an elastic blade, and the above-mentioned developer for developing a positively chargeable electrostatic latent image contains a positively chargeable toner (hereinafter referred to as known as toner) and a particular kind of fatty acid metal salt with a particular particle size distribution. In addition, the developer for developing a positively c...

no. 2 approach

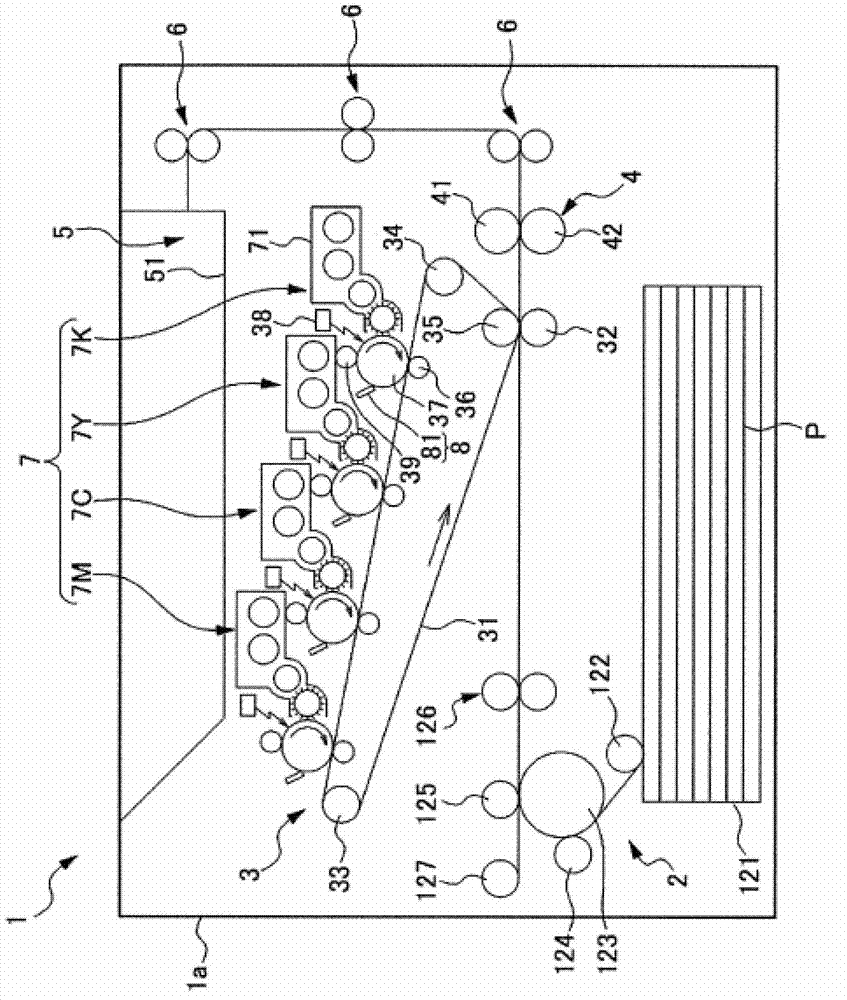

[0086] A second embodiment of the present invention relates to an image forming method in which an image is formed using the positively chargeable electrostatic latent image developing developer according to the first embodiment in an image forming apparatus including a latent image bearing unit and a cleaning unit. In the image forming method, in the image forming apparatus, the latent image bearing part has a photosensitive layer made of at least amorphous silicon formed on a conductive substrate, and the cleaning part has an elastic blade. Hereinafter, an image forming method according to a second embodiment of the present invention will be described.

[0087] The image forming apparatus used in the image forming method according to the second embodiment is not particularly limited as long as it includes a latent image bearing portion in which a photosensitive layer made of at least amorphous silicon is formed on a conductive substrate, and a cleaning portion having an elast...

preparation example 1

[0120] (Preparation of fatty acid metal salt particles)

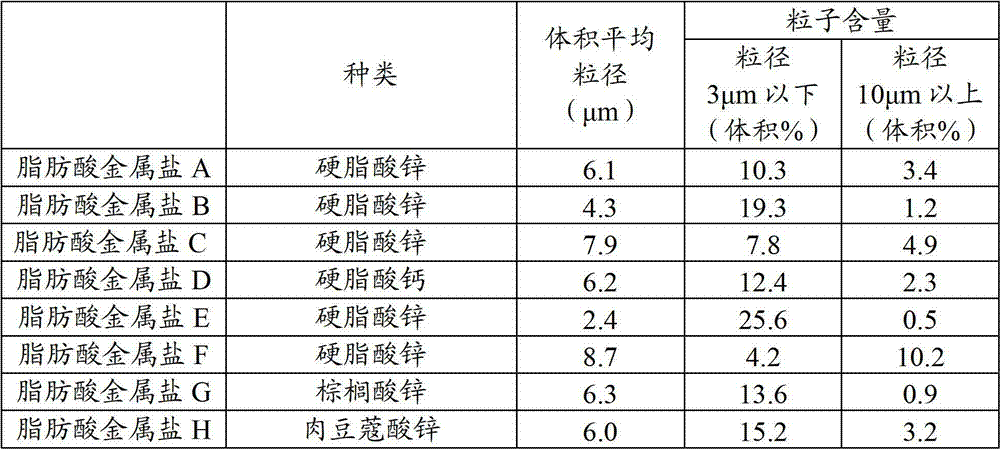

[0121] Zinc (II) stearate (SZ-TF (manufactured by Sakai Chemical Co., Ltd.), volume average particle size: 18 μm), hard Calcium stearate (calcium stearate FI (manufactured by NOF Corporation), volume average particle size 12.5 μm), zinc (II) palmitate (manufactured by Mitsuwa Chemicals Co., Ltd.), zinc (II) myristate (manufactured by Mitsu and Magnesium Stearate (manufactured by Taihei Chemical Industry Co., Ltd.) or magnesium stearate (manufactured by Taihei Chemical Industry Co., Ltd.), and the obtained pulverized material was classified with an elbow nozzle classifier (EJ-LABO type (manufactured by Nippon Steel Industries, Ltd.)). The crushing and classification conditions were appropriately adjusted to prepare fatty acid metal salts A to H described in Table 1. For the fatty acid metal salts A to H, the particle size distribution was measured with a particle size distribution analyzer (Malchisa Iza-3 (manufactured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com