Method for preparing salvianolic acid B magnesate

A technology of salvianolic acid and magnesium salt, which is applied in the field of extraction and separation of botanical medicinal materials, can solve the problems of high price, high cost and small output, and achieves the effects of simple process, low price and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

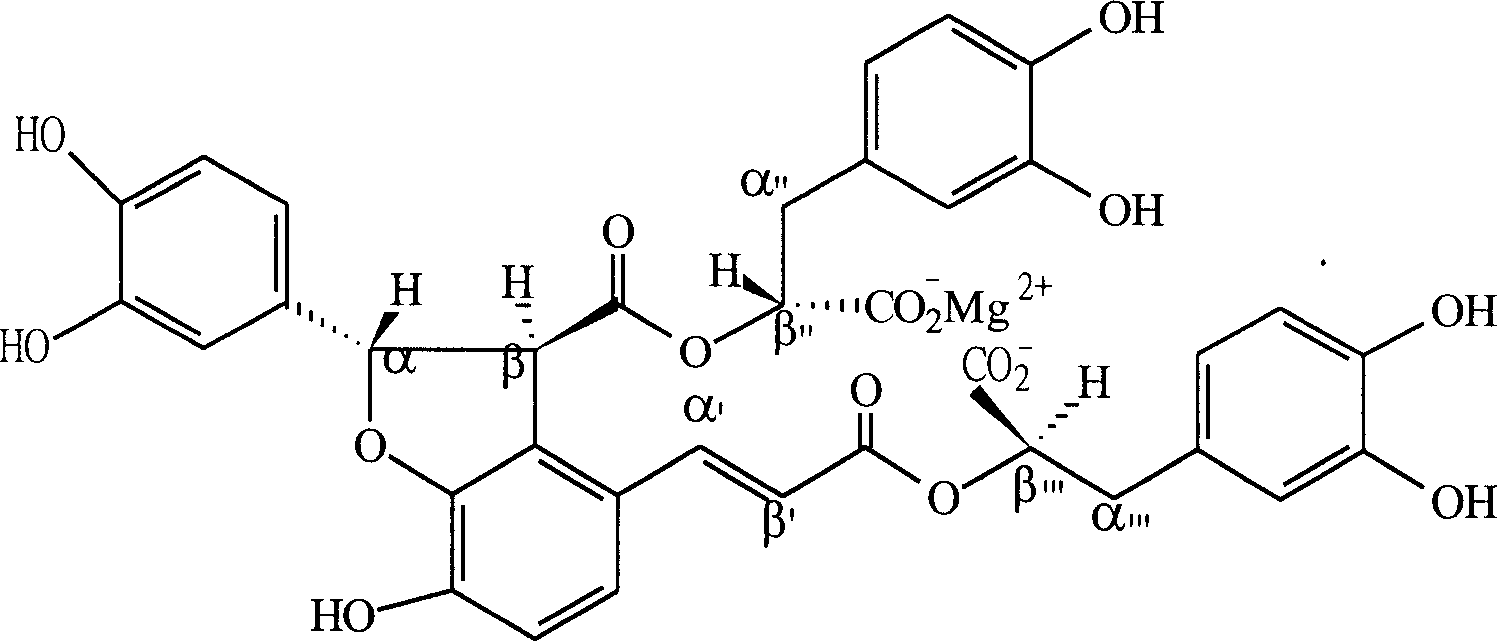

Image

Examples

Embodiment 1

[0019] 5 kg of Salvia miltiorrhiza medicinal materials, crushed through a 5-mesh sieve, soaked with a total amount of 20L of 60% acetone at 20°C for 6 hours, then released the soaking liquid. The solvent was evaporated under reduced pressure until there was no acetone smell, the precipitate was removed by centrifugation at 2000 rpm, and the D101 or D520 type macroporous adsorption resin was used for chromatography, eluted with water to remove impurities, then eluted with 20% ethanol, recovered ethanol, and freeze-dried. After the obtained product is dissolved in water, it is chromatographed with polyamide to remove impurities with water, and then eluted with 5% ethanol to obtain the salvianolic acid B magnesium salt component, which is concentrated under reduced pressure and freeze-dried. The content of the magnesium salt of salvianolic acid B determined by HPLC was 93.2%.

Embodiment 2

[0021] 5 kg of Salvia miltiorrhiza medicinal materials were crushed to 20 meshes, and the soaking liquid was released after being soaked in a total of 20 L of 80% ethanol at 20°C for 12 hours. The solvent was evaporated under reduced pressure until there was no alcohol smell, and the precipitate was removed by centrifugation at 4000 rpm. The AB-8 type macroporous adsorption resin was used for chromatography, eluted with water to remove impurities, then eluted with 30% ethanol, recovered ethanol, and freeze-dried. After the obtained product is dissolved in water, it is chromatographed with polyamide to remove impurities with water, and then eluted with 10% ethanol to obtain the salvianolic acid B magnesium salt component, which is concentrated under reduced pressure and freeze-dried. The content of magnesium salt of salvianolic acid B determined by high performance liquid chromatography was 90.8%.

Embodiment 3

[0023] Salvia miltiorrhiza medicinal material 5kg, crushed through a 10-mesh sieve, soaked with a total of 20L of 80% acetone at 40°C for 8 hours, then released the soaking liquid. The solvent was evaporated under reduced pressure until there was no acetone smell, and the precipitate was removed by centrifugation at 2000 rpm. The NKA-II type macroporous adsorption resin was used for chromatography, eluted with water to remove impurities, and then eluted with 20% and 40% ethanol successively to recover 40% ethanol Elution site. Then it was chromatographed with NKA-II type macroporous adsorption resin, eluted with water to remove impurities, collected the 20% ethanol eluted fraction, and freeze-dried. After the obtained product was dissolved in water, it was chromatographed with polyamide to remove impurities with water, and then eluted with 20% ethanol to obtain the component containing the magnesium salt of salvianolic acid B, concentrated under reduced pressure, freeze-dried, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com