Use of water-soluble zinc porphyrin complex in microcontact printing

A technology of micro-contact printing and porphyrin zinc, which is applied in the application field of water-soluble porphyrin zinc complexes in micro-contact printing, and achieves the effects of exquisite patterns, low preparation cost, and reduced use of organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Soak the polyethylene terephthalate substrate in 1mol / L sodium hydroxide at 70°C for 30 minutes, then soak it in 1mol / L acetic acid at 70°C for 15 minutes, then wash it with water, and dry it in vacuum at 60°C to obtain carboxylation base.

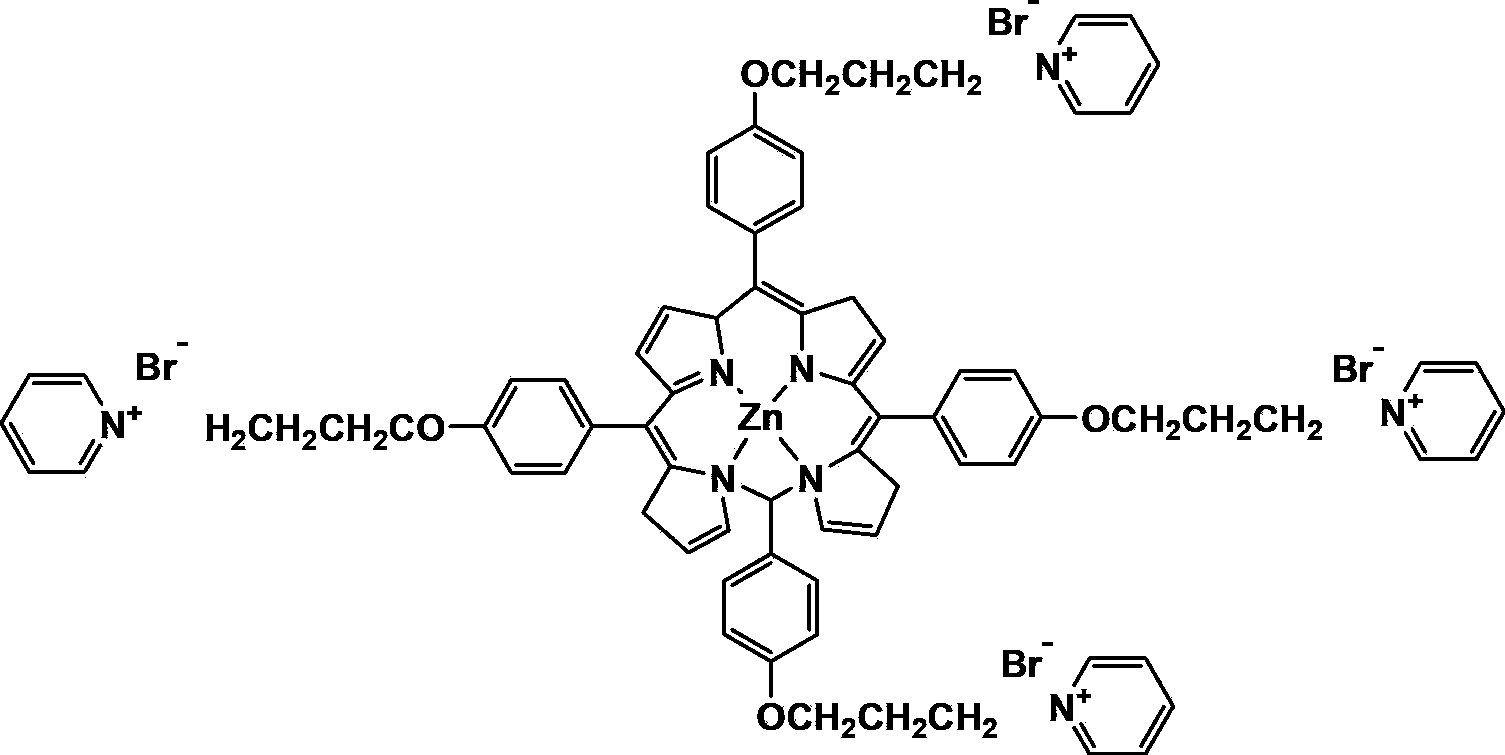

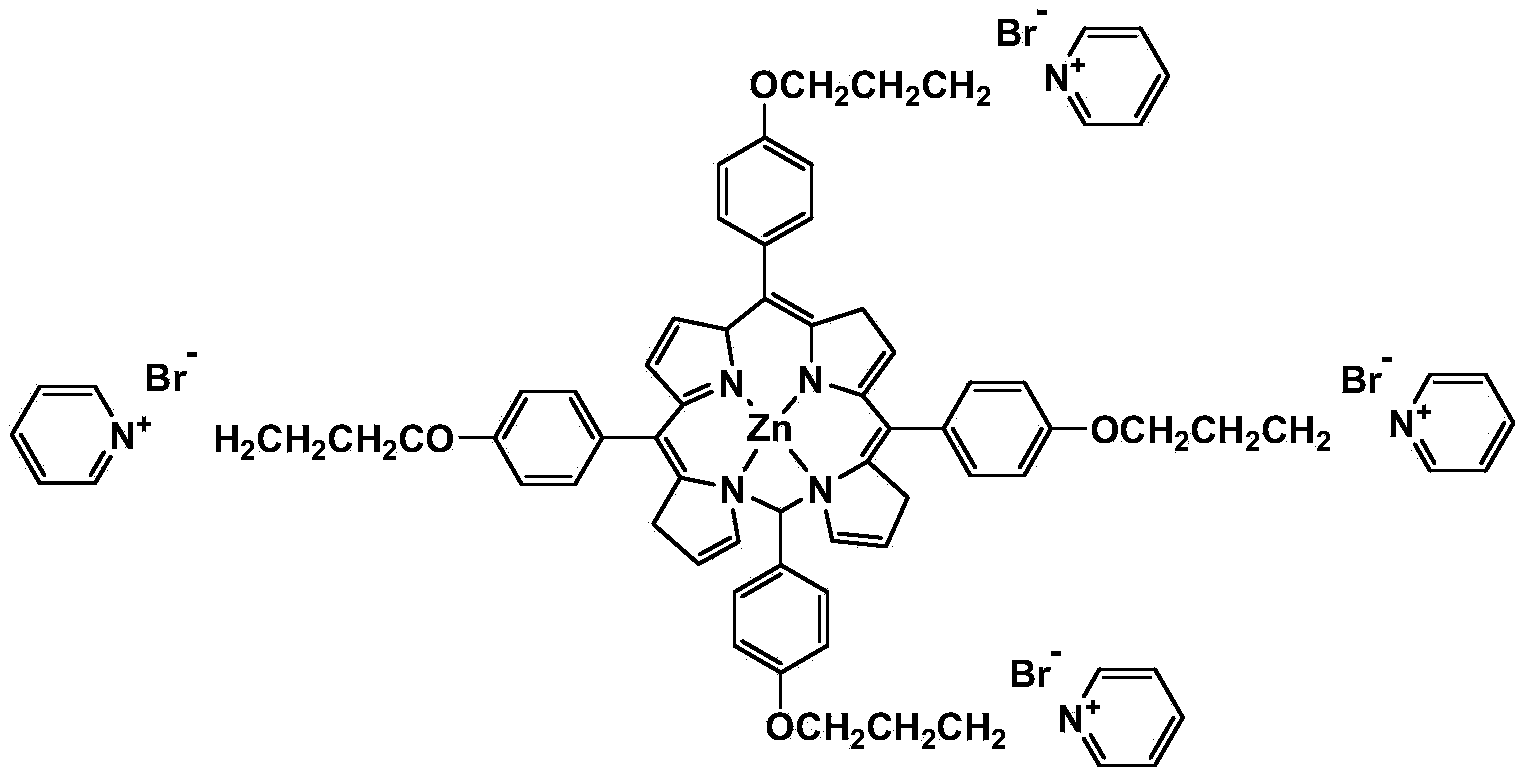

[0025] 2. Dissolve 5,10,15,20-tetrakis[4-(3'-propoxypyridinium bromide)phenyl]porphyrin zinc in water to obtain 5,10,15 with a concentration of 0.2g / L, 20-Tetrakis[4-(3'-propoxypyridinium bromide)phenyl]porphyrin zinc aqueous solution.

[0026] 3. Soak the PDMS stamp in the 5,10,15,20-tetrakis[4-(3'-propoxypyridinium bromide salt)phenyl]porphyrin zinc aqueous solution prepared in step 2 for 30s, take it out and place it under N 2 Dry in air flow for 30s. Put the PDMS stamp coated with 5,10,15,20-tetrakis[4-(3'-propoxypyridinium bromide salt)phenyl]porphyrin zinc aqueous solution on the carboxylated substrate, press lightly for 5s, The PDMS stamp pattern is transferred to the surface of the substrate to obtain a pattern-printed...

Embodiment 2

[0029] 1. Soak the polyethylene terephthalate substrate in 3mol / L sodium hydroxide at 70°C for 30 minutes, then soak it in 3mol / L acetic acid at 70°C for 15 minutes, then wash it with water, and dry it in vacuum at 60°C to obtain carboxylation base.

[0030] 2. Dissolve 5,10,15,20-tetrakis[4-(3'-propoxypyridinium bromide)phenyl]porphyrin zinc in water to obtain 5,10,15 with a concentration of 0.5g / L, 20-Tetrakis[4-(3'-propoxypyridinium bromide)phenyl]porphyrin zinc aqueous solution.

[0031] 3. Soak the PDMS stamp in the 5,10,15,20-tetrakis[4-(3'-propoxypyridinium bromide salt)phenyl]porphyrin zinc aqueous solution prepared in step 2 for 30s, take it out and place it under N 2 Dry in air flow for 30s. Put the PDMS stamp coated with 5,10,15,20-tetrakis[4-(3'-propoxypyridinium bromide salt)phenyl]porphyrin zinc aqueous solution on the carboxylated substrate, press lightly for 5s, Transfer the PDMS stamp pattern to the substrate surface.

[0032] 4. Soak the patterned substra...

Embodiment 3

[0034] 1. Soak the polyethylene terephthalate substrate in 5mol / L sodium hydroxide at 70°C for 30 minutes, then soak it in 5mol / L acetic acid at 70°C for 15 minutes, then wash it with water, and dry it in vacuum at 60°C to obtain carboxylation base.

[0035] 2. Dissolve 5,10,15,20-tetrakis[4-(3'-propoxypyridinium bromide)phenyl]porphyrin zinc in water to obtain 5,10,15 with a concentration of 0.8g / L. 20-Tetrakis[4-(3'-propoxypyridinium bromide)phenyl]porphyrin zinc aqueous solution.

[0036] 3. Soak the PDMS stamp in the 5,10,15,20-tetrakis[4-(3'-propoxypyridinium bromide salt)phenyl]porphyrin zinc aqueous solution prepared in step 2 for 30s, take it out and place it under N 2 Dry in air flow for 30s. Put the PDMS stamp coated with 8-5,10,15,20-tetrakis[4-(3'-propoxypyridinium bromide salt)phenyl]porphyrin zinc aqueous solution on the carboxylated substrate and press lightly for 5s , transfer the PDMS stamp pattern to the substrate surface.

[0037] 4. Soak the patterned s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com