Solar seawater desalination or sewage treatment method based on carbon nano-tube film

A technology of carbon nanotube film and sewage treatment method, which is applied in water/sewage treatment, water/sludge/sewage treatment, seawater treatment, etc., can solve the problems of high cost and complicated production process, and achieve simple process and wide application Prospect, durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

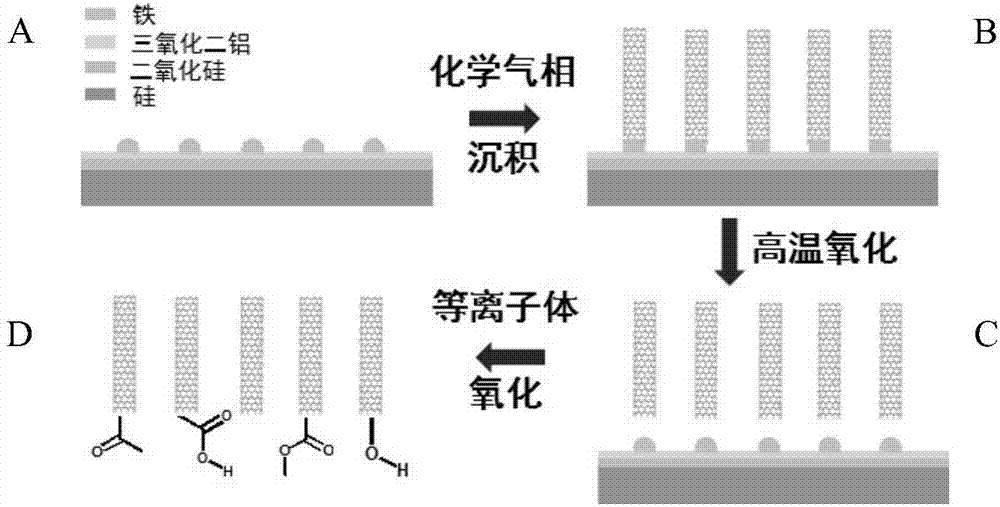

[0067] Embodiment 1: Preparation of vertical array of carbon nanotubes

[0068] S1. Depositing the catalyst required for growing carbon nanotubes on a silicon wafer containing a silicon dioxide film with a thickness of 800 nm. In this embodiment, the method of electron beam evaporation is used to deposit the catalyst, which specifically includes first evaporating a layer of 10nm aluminum oxide on the silicon dioxide film, and then evaporating a layer of 2-5nm iron oxide on the aluminum oxide layer. .

[0069] S2. After the vapor deposition, the substrate (ie, the silicon wafer) is ultrasonically cleaned. The cleaning process includes ultrasonication with acetone, ethanol, and water for 15 minutes each.

[0070] S3. Put the substrate into the tubular heating furnace, feed the carbon source reaction gas and raise the temperature:

[0071] S3.1. The carbon source gas introduced is ethylene, and the feeding rate is 30 milliliters per minute (unit: sccm). The auxiliary gas uses a...

Embodiment 2

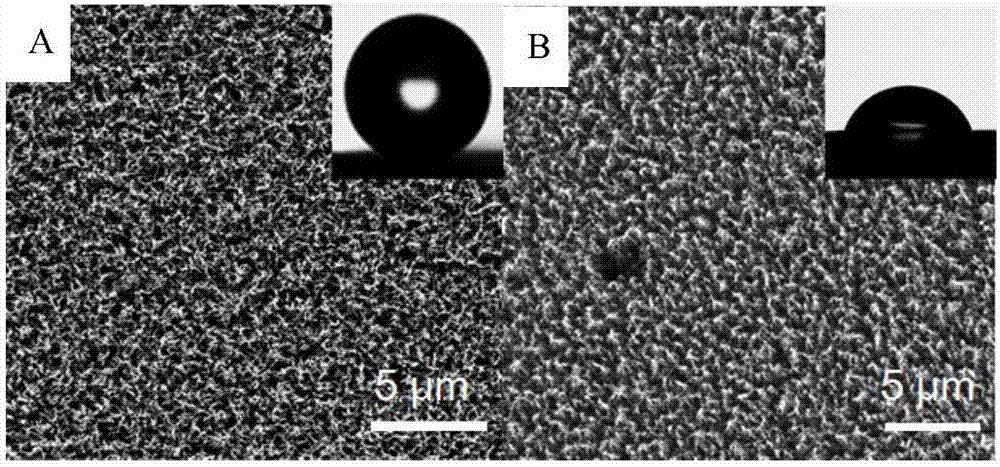

[0075] Embodiment 2: the preparation method of hydrophilic carbon nanotube film

[0076] method 1:

[0077] S1. In the reaction of Example 1, after the chemical vapor deposition reaction is completed, turn off the ethylene and hydrogen, keep the reaction temperature at 750° C., and carry out high-temperature oxidation for 5-10 minutes. The gas atmosphere used for high-temperature oxidation is argon and oxygen. Wherein the oxygen feed rate is less than 2%.

[0078] S2. After the temperature of the tubular heating furnace drops to room temperature, remove the vertical array of carbon nanotubes after high-temperature oxidation from the substrate, and perform plasma etching, so that the ends of the carbon tubes will have more oxygen-containing functional groups and become Hydrophilic. The gas used in the plasma etching process is air, the power is 50-60w, and the oxidation time is 120-300s.

[0079] Method 2:

[0080] In the reaction of Example 1, ethylene was turned off after...

Embodiment 3

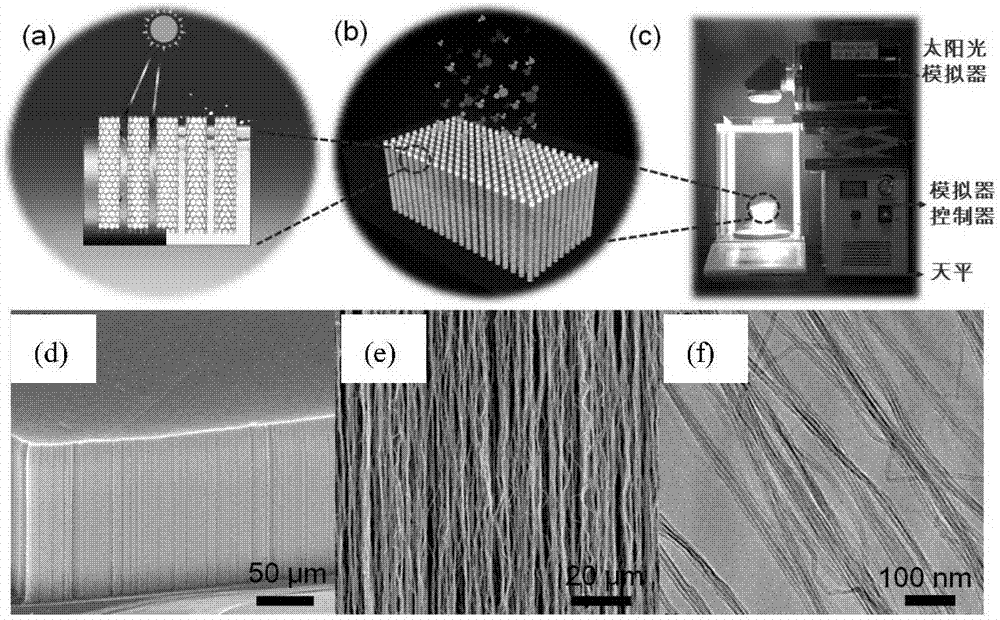

[0084] Example 3: Water evaporation test using carbon nanotube film as light-to-heat conversion layer

[0085] like image 3 As shown, the carbon nanotube film obtained in Example 2 is transferred to the surface of a water body (tap water), and under the irradiation of a solar simulator (xenon lamp light source), water vapor can be generated. Put the beaker containing water and carbon nanotube film on the electronic balance (see image 3 c) Connect the electronic balance to the computer, and the change of the balance can be recorded through the data recording program, so as to calculate the change of water vapor. By calculating the change of water vapor within a certain period of time, the evaporation rate of water can be obtained, and then the evaporation efficiency can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com