MXene nanowire composite electrospinning fiber membrane for photothermal desalting

A technology of electrospun fibers and nanowires, applied in the field of water treatment, can solve the problems of increasing the complexity of the membrane distillation system, unfavorable engineering development, poor absorption capacity, etc., and achieves convenience for large-scale production and use, high mechanical strength, and improved The effect of absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

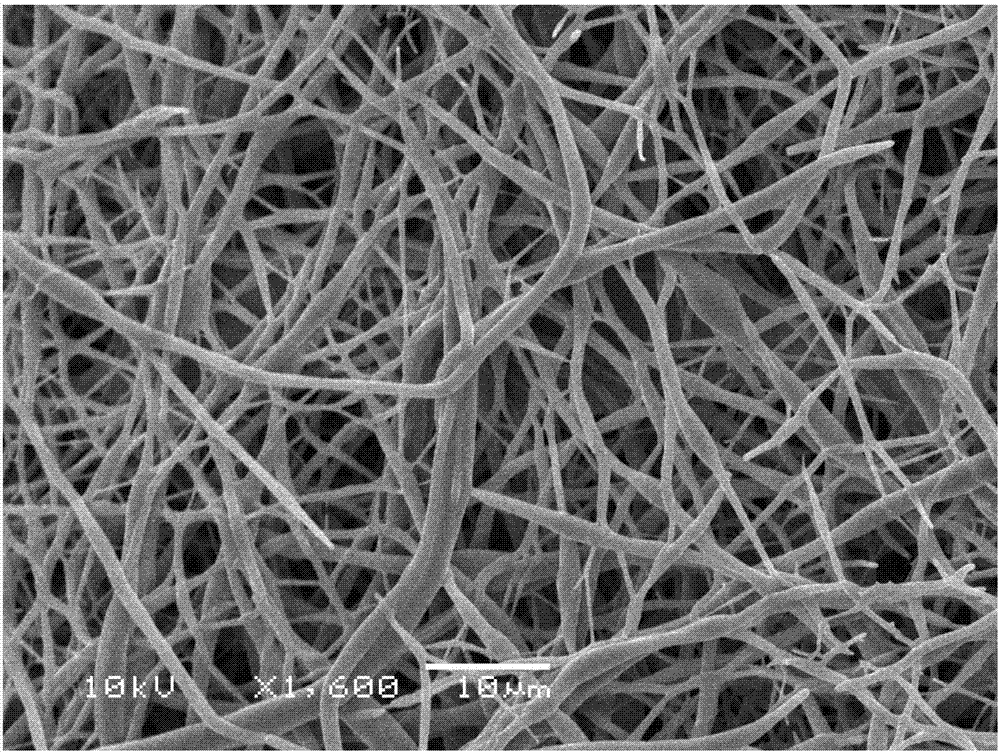

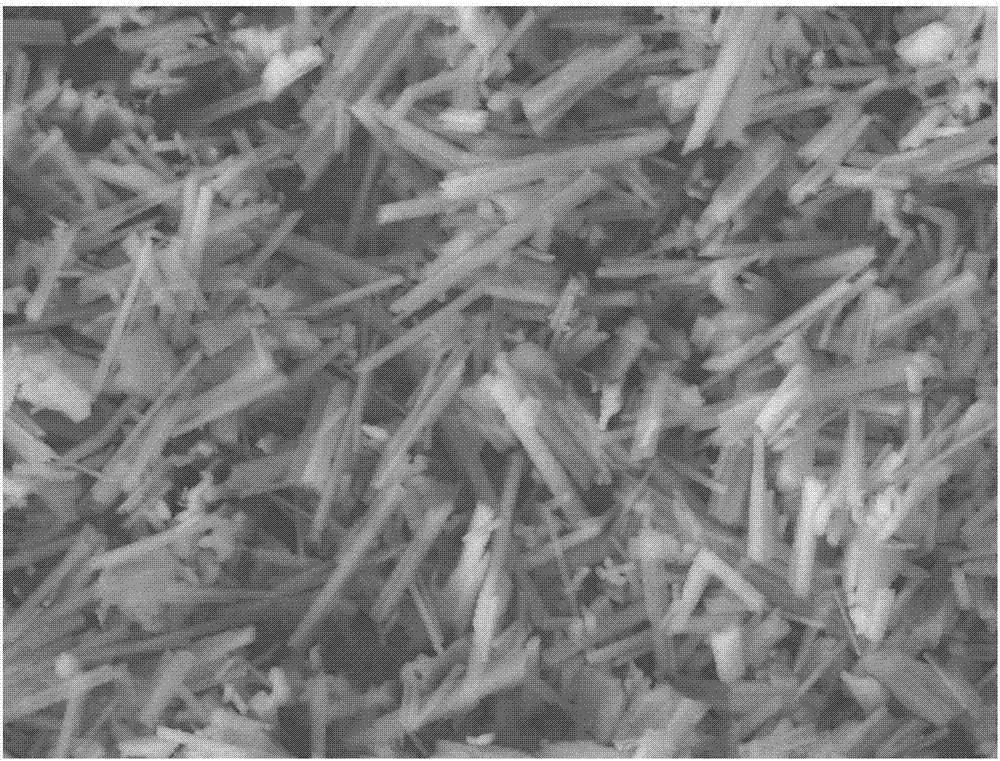

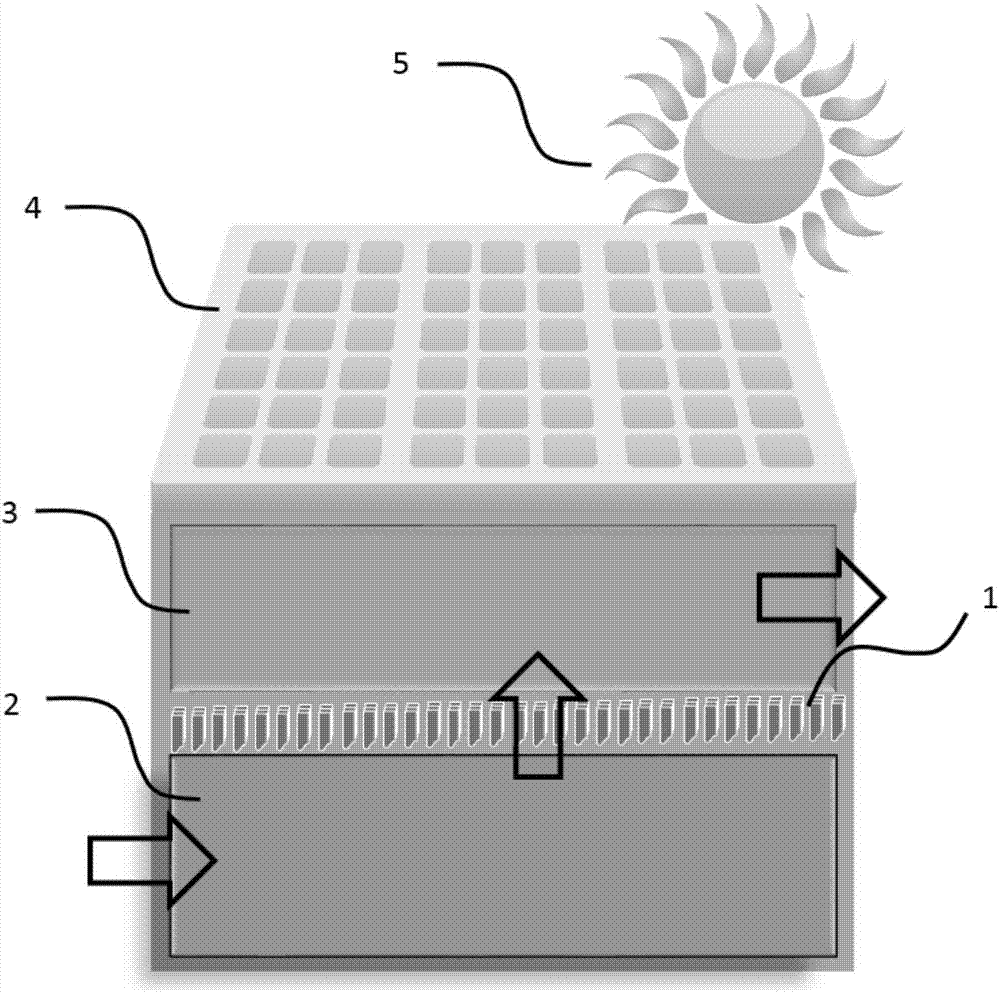

[0035] The MXene nanowire composite electrospun fiber membrane for photothermal desalination is prepared by the following steps: taking Ti 3 AlC 2 2.15g, added to dilute HCl with a mass concentration of 5% and a mass concentration of 15% CaF 2Stir vigorously in a polytetrafluoroethylene flask, keep at 60°C, and continuously expose to hydrogen bubbles during the reaction. After 24 hours of reaction, a gray-black exfoliated MXene phase product is obtained. Soak the product in the acetic acid solution of HF, add methyl acrylate inducer, the mass concentrations of MXene and methyl acrylate are 100g / L and 2.5g / L respectively, the acetic acid solution is sealed in the autoclave, and the autoclave Put it in a muffle furnace, heat it to form a supercritical environment in the kettle for solvothermal reaction, keep it warm for 48 hours, anneal to room temperature, filter, wash, and get MXene nanowires with a regular shape. The nanowires are ground in a ball mill to shorten aspect rat...

no. 2 example

[0037] The second embodiment is a modified example of the first embodiment, the difference from the first embodiment is that the MAX material is replaced by Ti 3 SiC 2 , the concentration of dilute hydrochloric acid is 10%, the concentration of MXene in acetic acid is 150g / L, the concentration of methyl acrylate in acetic acid is 3.5g / L, other conditions and dosage are the same as those of the first embodiment, and will not be repeated here .

no. 3 example

[0039] The third embodiment is a modified example of the first embodiment, the difference from the first embodiment is that the MAX material is replaced by Ti 3 SiC 2 , the concentration of dilute hydrochloric acid is 7.5%, the concentration of MXene in acetic acid is 122g / L, the concentration of methyl acrylate in acetic acid is 2.7g / L, other conditions and dosage are the same as those of the first embodiment, and will not be repeated here .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com