Flame-retarded polyamide 6 and preparation method thereof

A technology for flame retardant polyamide and polyamide, which is applied in the field of flame retardant polyamide 6 and its preparation, can solve the problems of poor mechanical properties and poor flame retardant performance of polyamide 6, and achieves excellent flame retardant performance and good flame retardant effect. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

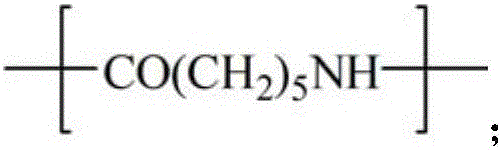

[0044] A preparation method of flame retardant polyamide 6, the steps are as follows:

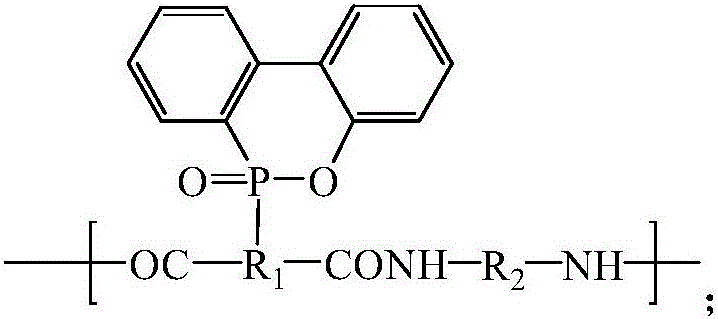

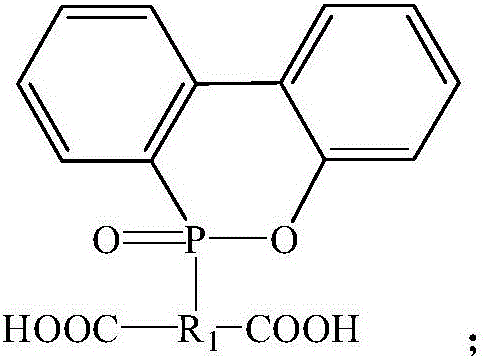

[0045] 1) Mix the DOPO-based reactive phosphorus-based flame retardant, diamine and water at a stirring speed of 50 r / min, and conduct a salt-forming reaction at 60 °C for 2 h to obtain a flame retardant salt. Among them, DOPO-based reactive phosphorus The molar ratio of flame retardant and diamine is 1:1, and the mass ratio of DOPO-based reactive phosphorus-based flame retardant and water is 1:1; the structural formula of DOPO-based reactive phosphorus-based flame retardant is:

[0046]

[0047] The structural formula of the diamine is NH 2 -(CH 2 ) 3 -NH 2 ;

[0048] 2) In parts by weight, 3 parts of aluminum diethylphosphinate, 100 parts of caprolactam and 2 parts of water were added to the reaction kettle, stirred and heated to 250° C. The stirring rate was 50r / min, and when the pressure reached 0.8MPa , heat preservation and pressure holding reaction for 3h, and then release th...

Embodiment 2

[0057] A preparation method of flame retardant polyamide 6, the steps are as follows:

[0058] 1) Mix and stir DOPO-based reactive phosphorus-based flame retardant, diamine and ethanol at a stirring rate of 80 r / min and conduct a salt-forming reaction at 63 °C for 2 h to obtain a flame retardant salt. Among them, DOPO-based reactive phosphorus The molar ratio of flame retardant and diamine is 1:1, the mass ratio of DOPO-based reactive phosphorus-based flame retardant and ethanol is 1:1.1; the structural formula of DOPO-based reactive phosphorus-based flame retardant is:

[0059]

[0060] The structural formula of the diamine is NH 2 -(CH 2 ) 10 -NH 2 ;

[0061] 2) In parts by weight, add 3 parts of zinc diethylphosphinate, 1 part of zinc stannate, 99 parts of caprolactam, 0.1 part of adipic acid and 2 parts of water to the reaction kettle, stir and heat up to 251 ° C, stir The rate is 100r / min. When the pressure reaches 0.9MPa, the reaction is kept under pressure for 2...

Embodiment 3

[0070] A preparation method of flame retardant polyamide 6, the steps are as follows:

[0071] 1) Mix the DOPO-based reactive phosphorus-based flame retardant, diamine and water at a stirring rate of 100 r / min, and conduct a salt-forming reaction at 66 °C for 3 hours to obtain a flame retardant salt. Among them, DOPO-based reactive phosphorus The molar ratio of flame retardant and diamine is 1:1.1, and the mass ratio of DOPO-based reactive phosphorus-based flame retardant and water is 1:1.2; the structural formula of DOPO-based reactive phosphorus-based flame retardant is:

[0072]

[0073] The structural formula of the diamine is NH 2 -(CH 2 ) 5 -NH 2 ;

[0074] In parts by weight, 5 parts of aluminum methyl butyl phosphinate, 97 parts of caprolactam, 1 part of adipic acid and 3 parts of water were added to the reaction kettle, stirred and heated to 252 ° C, and the stirring rate was 200 r / min. When the pressure reaches 1MPa, the reaction is kept under pressure for 3h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com