Organic silicon compound containing phosphorus and its preparing method

An organosilicon compound and siloxane technology, applied in the field of phosphorus-containing organosilicon compounds and their preparation, can solve the problems of inability to prepare additive flame retardants and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 216g (1mol) of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (solid) and 132g (1mol) of vinyldimethoxysiloxane (liquid) to three In the neck flask, stir, heat and dissolve, control the temperature at 105°C, continue to add 36g (2mol) H after reflux reaction for 12 hours 2 O, 1.12g (0.02mol) potassium hydroxide, the temperature was kept at 100°C, reacted for 10 hours, decompressed to remove water and the methanol produced by the reaction for 3 hours, and cooled to obtain 297g of light yellow viscous liquid, which was the reaction product A Base-[2-(9-oxa-10-phosphaphenanthrene-10-oxide)-ethyl]-dihydroxysilane with a yield of 92.8%.

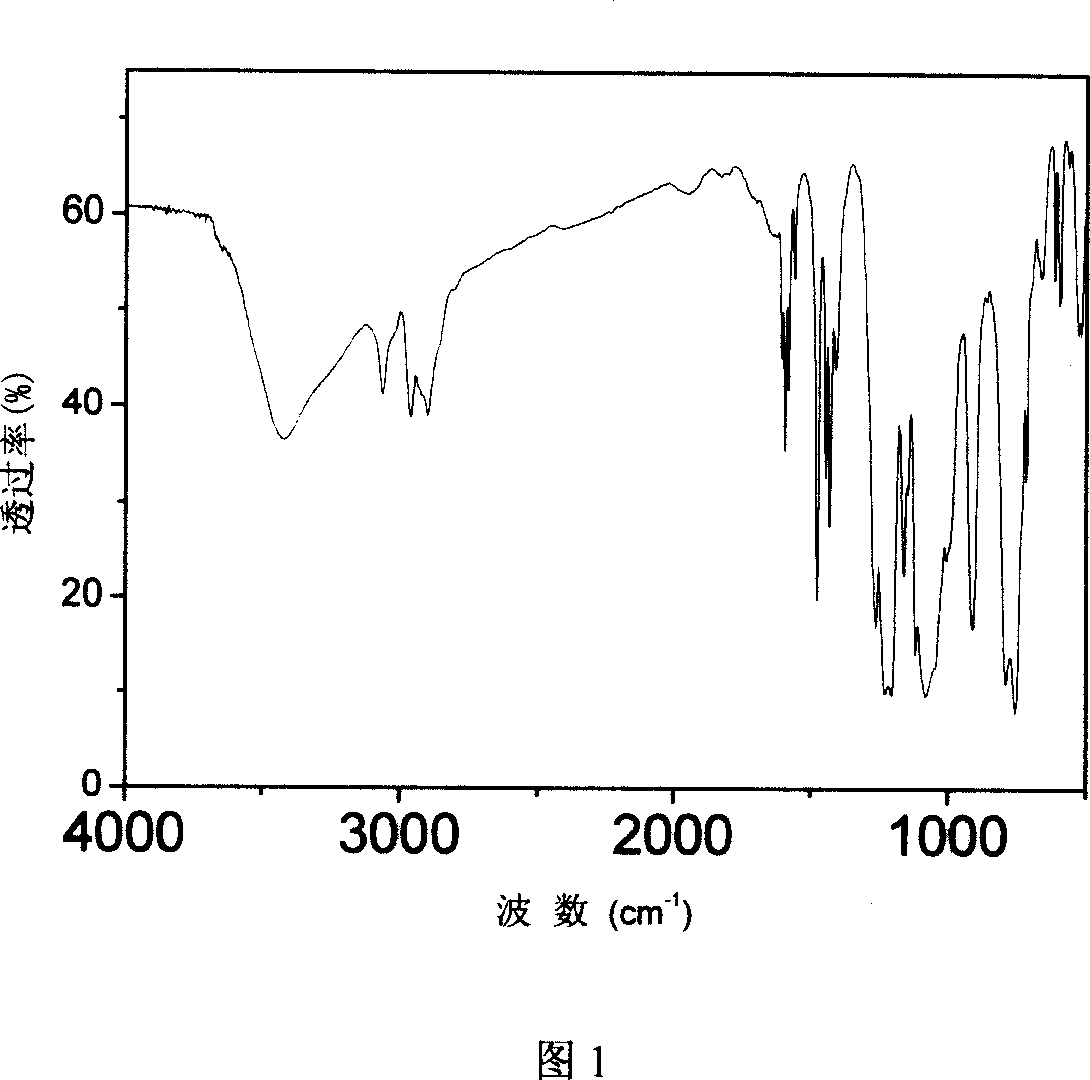

[0028] Fig. 1 is the infrared spectrogram of methyl-[2-(9-oxa-10-phosphaphenanthrene-10-oxide)-ethyl]-dihydroxysilane; FTIR (KBr, cm -1 ): 3421(OH), 3064(C-H in phenyl group), 2800-3000(CH 2 , CH 3 ), 1595(phenyl group), 1477(P-phenyl), 1410(P-CH 2 -of aliphatic), 1206 (P=O), 1004-1117 (Si-O-Si), 911 (P-O-phenyl)

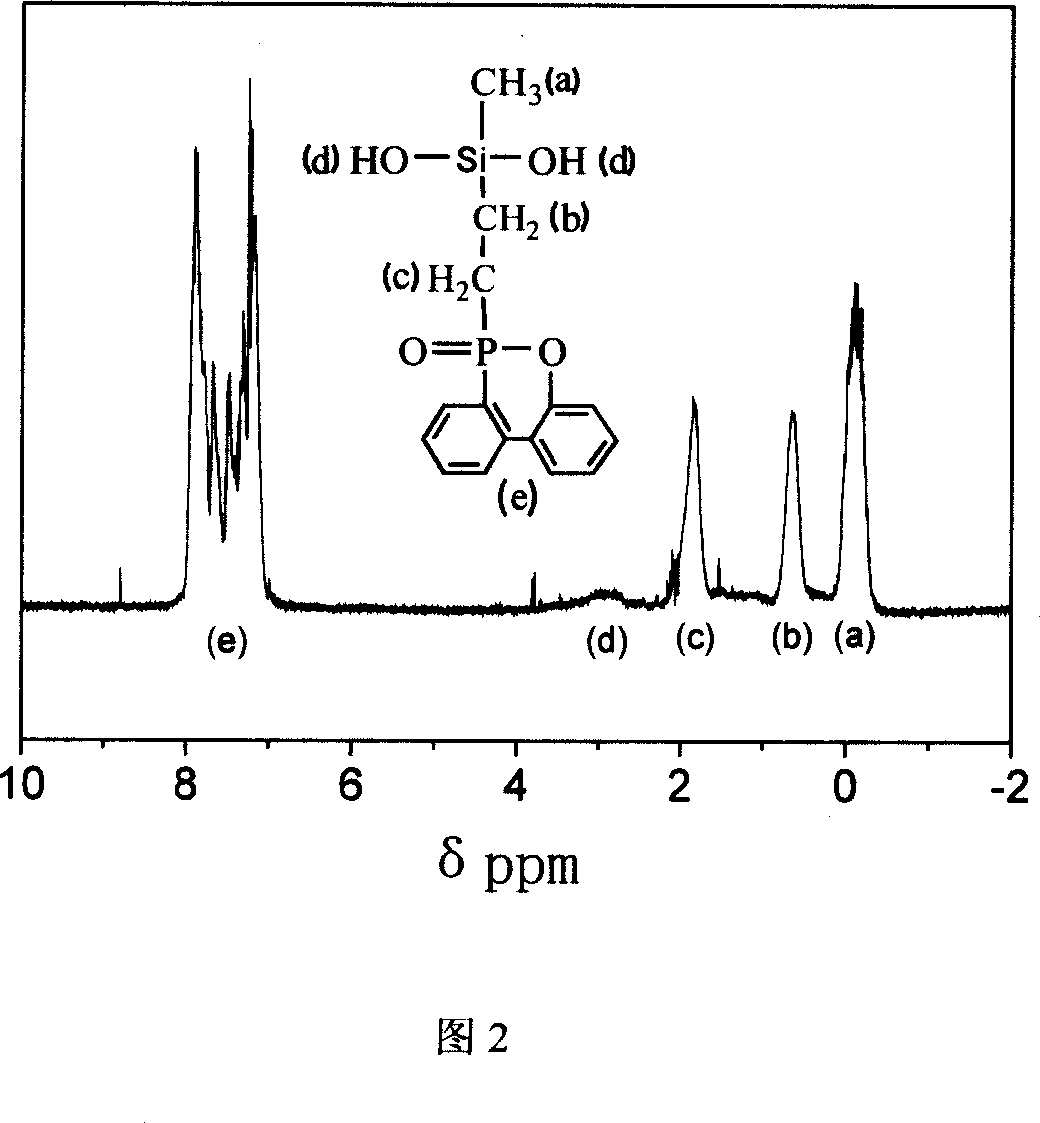

[0029] Fig. ...

Embodiment 2

[0032] Add 216g (1mol) of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (solid) and 191g (1mol) of vinyltriethoxysiloxane (liquid) to three In the flask, stir, heat to dissolve, control the temperature to 160°C, and continue to add 36g (2mol) H after reflux reaction for 12 hours 20, 1.12g (0.02mol) potassium hydroxide, the temperature is maintained at 100 ℃, reacted for 10 hours, removed water under reduced pressure and the low-boiling point small molecule ethanol generated by the reaction for 4 hours, cooled to obtain 305g of light yellow viscous liquid, which is The reaction product [2-(9-oxa-10-phosphaphenanthrene-10-oxide)-ethyl]-trihydroxysilane has a yield of 94.7%.

Embodiment 3

[0034] Methyl-[2-(9-oxa-10-phosphaphenanthrene-10-oxide)-ethyl]-dihydroxysilane 160g obtained by Example 1, 20.6g N-(β-aminoethyl) -α-Aminopropylmethyldimethoxysilane, 3.6g H 2 O and 0.12g potassium hydroxide were added in the three-necked flask, heated and dissolved, stirred, controlled temperature was 100°C, reacted for 24 hours, removed water under reduced pressure and the low-boiling point small molecule methanol generated by the reaction for 8 hours, cooled to obtain Phosphorus-containing polysiloxane 157g, yield 94.0%.

[0035] The obtained phosphorus-containing polysiloxane 21g, polycarbonate (PC) 34.3g, acrylonitrile-butadiene-styrene terpolymer (ABS) 14.7g are put into internal mixer and mix evenly, knead The temperature is 210°C, the mixing time is 6 minutes, and the flame-retardant PC / ABS alloy is obtained. The oxygen index is 27.2, which reaches the UL-94V-0 level, and a relatively high carbon formation rate is obtained at 800°C (in nitrogen: 16.7%; in air: 14.3%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com