Halogen-free flame-retardant electromagnetic shielding material and preparation method and application thereof

A technology of electromagnetic shielding materials and flame retardants, which is applied in the fields of magnetic/electric field shielding, electrical components, fireproof coatings, etc. It can solve problems such as non-conductivity of the bonding surface, reflection loss on the surface of the shielding body, and difficulty in meeting the latest requirements. Achieve high electromagnetic shielding efficiency, optimization of electromagnetic shielding, optimization of mechanical properties and other properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

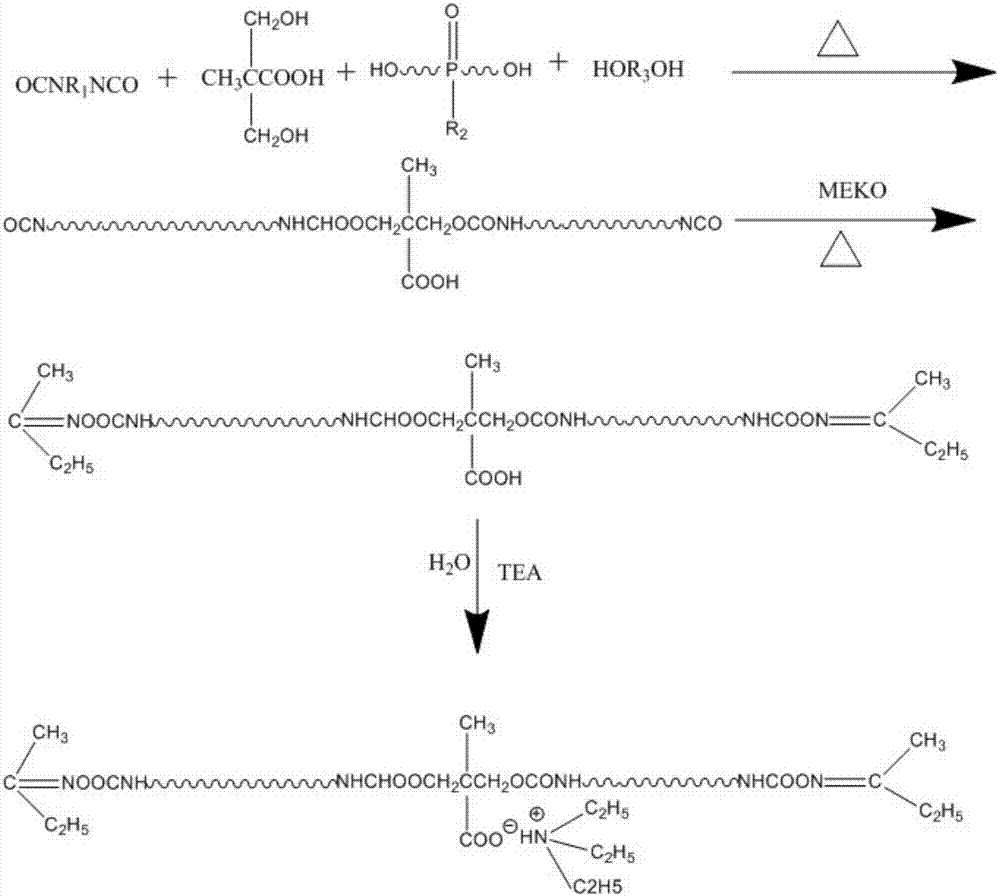

[0067] Taking the preparation, deblocking and crosslinking of phosphorus-containing blocked isocyanate as an example, the reaction formula in the typical application of the present invention can be seen from the following reaction formula schematic diagram as follows:

[0068]

[0069] Among them, HOR 3 OH is polyether polyol (for example, polyether polyol such as N210 / N220).

[0070] The typical crosslinking reaction formula is as follows (take the deblocking and crosslinking of phosphorus-containing blocked isocyanate as an example):

[0071]

[0072] It can be seen from the above reaction formula that the flame-retardant crosslinking agent and flame-retardant polymer adhesive through the chemical reaction and the combination of the polymer chain, so that various flame-retardant raw materials and conductive materials are firmly bonded to the substrate, thereby achieving good Application performance.

[0073] The halogen-free flame-retardant electromagnetic shielding material of the ...

Embodiment 1

[0076] In a stirring vessel, add 10 grams of non-ionic wetting agent W-18 (Hemmings Deqian (Shanghai) Chemical Co., Ltd.), and 10 grams of polycarboxylate sodium salt anionic dispersant SN5040 (Weifang Dadong Chemical Co., Ltd.) ) Disperse in 500 grams of water-based flame-retardant polyurethane TF-686 (Zhejiang Chuanhua Co., Ltd. TF-686, solid content 40%), the stirring speed is 300RPM;

[0077] Under the condition of stirring and dispersing, add 150 grams of conductive nickel powder, 300 grams of type II ammonium polyphosphate with a degree of polymerization greater than 1000, add 400 grams of water, and continue to disperse at 600 RPM;

[0078] Under the condition of stirring and dispersing, add 5 grams of K3 defoamer (mineral oil defoamer), 20 grams of flame retardant crosslinking agent polycarbodiimide, and 150 grams of liquid flame retardant resorcinol phosphate (RDP ), 100 grams of flame retardant synergist melamine borate (Sichuan Zhuoan New Material Technology Co., Ltd.), ...

Embodiment 2

[0082] Weigh 956 grams of phosphorus-containing polyester diol DM1304 (Beijing Demei Kechuang Technology Co., Ltd. DM1304, molecular weight 478, hydroxyl value 233mgKOH / g, phosphorus content (wt, %) 19.7%), 134 grams of dimethylol propylene Acid and 400 grams of polyether polyol N210 (Nanjing Zhongshan Chemical Co., Ltd.), drop 870 grams of toluene diisocyanate (Yantai Wanhua Chemical Group Co., Ltd.) for polycondensation reaction, control the molar ratio of NCO / OH in the material at 1.5 :1, add 100 grams of butanone and react at 78°C for 2.0 hours;

[0083] Use 298.3 grams of methyl ethyl ketoxime (Zhejiang Quzhou New Future Chemical Co., Ltd.) to cap the residual NCO of the end group, and react at 70°C for 1.0 hour;

[0084] Use 101 grams of triethylamine for neutralization, the molar ratio of triethylamine to dimethylolpropionic acid is 1:1, and the degree of neutralization is controlled at 100%;

[0085] Add 5713 grams of deionized water, emulsify at a high speed at 1400 RPM, af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com