Polyester resin color master batch and preparation method thereof

A technology of polyester resin and color masterbatch, applied in the field of polyester resin masterbatch and its preparation, can solve the problems of dispersibility, poor heat resistance, alkali resistance and weather resistance, and achieves improved alkali resistance and weather resistance, Improve dispersibility and heat resistance, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

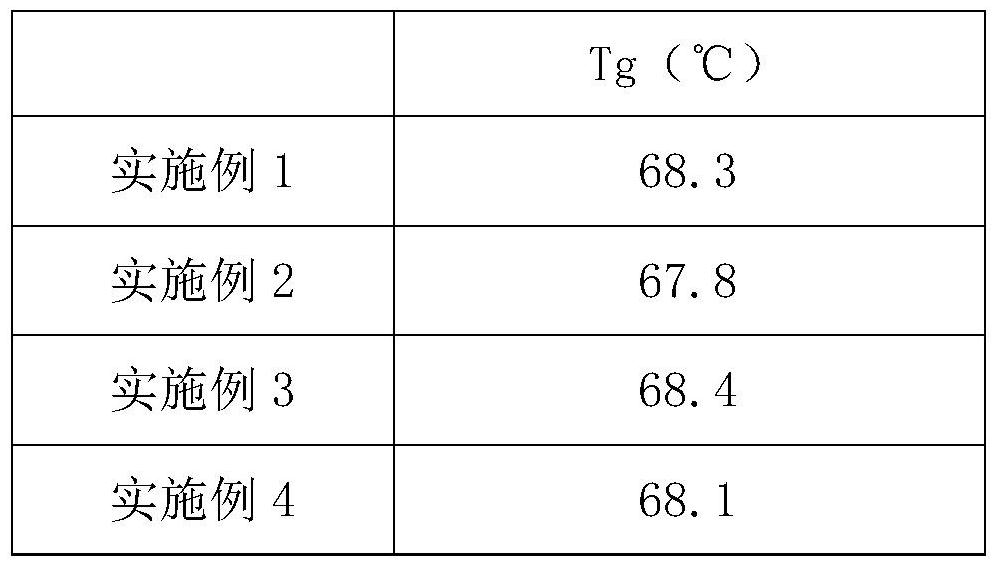

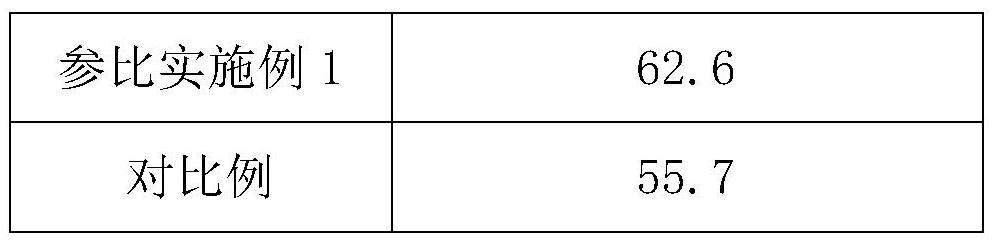

Examples

Embodiment 1

[0025] Polyester resin master sand, made from the following raw materials by weight: 50% toner, 3% dispersant, 1.5% nano-zinc oxide, 2.5% laureth, 1% stearamide, 1,1 , 1.5% of 3,3-tetramethyl-1,3-divinylsilazane, the rest are polyester resin, and the sum of the weight percentages of each raw material is 100%.

[0026] The dispersant is made by the following steps:

[0027] Under a nitrogen atmosphere, add methyl ethyl ketone peroxide into absolute ethanol, stir evenly, and mix with polyethylene wax, acrylic acid, and water. The ratio of methyl ethyl ketone peroxide, absolute ethanol, polyethylene wax, acrylic acid, and water is 0.15g:10mL. : 30g: 5g: 70mL, heated to 45°C and left to stand for 2 hours, then heated to 85°C and stirred for 3 hours, cooled to 45°C and discharged to obtain a reaction solution, the reaction solution was filtered to obtain a solid, and the solid was washed with water To neutrality, it was placed in an oven at 70°C and dried to constant weight to obt...

Embodiment 2

[0032] Polyester resin master sand, made from the following raw materials by weight: toner 55%, dispersant 2%, nano-zinc oxide 2%, laureth 2%, stearamide 1.2%, 1,1 , 1.6% of 3,3-tetramethyl-1,3-divinylsilazane, the rest are polyester resin, and the sum of the weight percentages of each raw material is 100%.

[0033] The dispersant is made by the following steps:

[0034] Under a nitrogen atmosphere, add methyl ethyl ketone peroxide into absolute ethanol, stir evenly, and mix with polyethylene wax, acrylic acid, and water. The ratio of methyl ethyl ketone peroxide, absolute ethanol, polyethylene wax, acrylic acid, and water is 0.15g:10mL. : 30g: 5g: 70mL, heated to 45°C and left to stand for 2 hours, then heated to 85°C and stirred for 3 hours, cooled to 45°C and discharged to obtain a reaction solution, the reaction solution was filtered to obtain a solid, and the solid was washed with water To neutrality, it was placed in an oven at 70°C and dried to constant weight to obtai...

Embodiment 3

[0039] Polyester resin masterbatch, made from the following raw materials by weight: toner 45%, dispersant 4%, nano-zinc oxide 1.8%, laureth 2.1%, stearamide 1.5%, 1,1 , 1% of 3,3-tetramethyl-1,3-divinylsilazane, the rest are polyester resin, and the sum of the weight percentages of each raw material is 100%.

[0040] The dispersant is made by the following steps:

[0041] Under a nitrogen atmosphere, add methyl ethyl ketone peroxide into absolute ethanol, stir evenly, and mix with polyethylene wax, acrylic acid, and water. The ratio of methyl ethyl ketone peroxide, absolute ethanol, polyethylene wax, acrylic acid, and water is 0.15g:10mL. : 30g: 5g: 70mL, heated to 45°C and left to stand for 2 hours, then heated to 85°C and stirred for 3 hours, cooled to 45°C and discharged to obtain a reaction solution, the reaction solution was filtered to obtain a solid, and the solid was washed with water To neutrality, it was placed in an oven at 70°C and dried to constant weight to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com