Composite reagent for hydrometallurgy as well as preparation method and application thereof

A composite agent and hydrometallurgy technology, which is applied in the field of hydrometallurgy industry, can solve the problems of increasing production operation cost, increasing two-phase separation time, affecting metal extraction efficiency, etc., achieving clear two-phase interface, small amount of agent, and high treatment efficiency. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

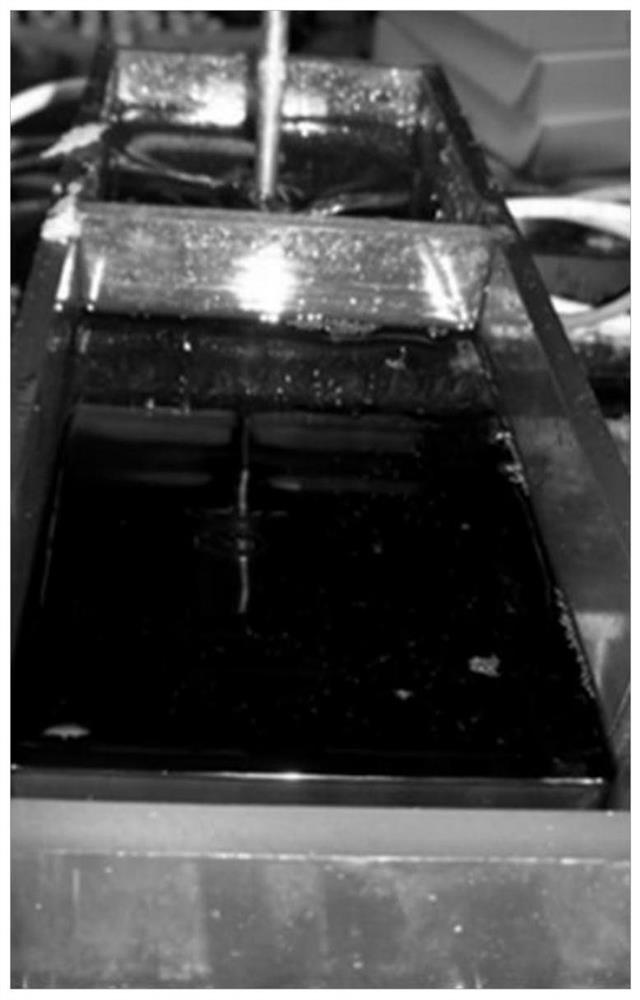

Image

Examples

Embodiment 1

[0030] Add 900 g of deionized water to the configuration slot, then sequentially added 50 g of sodium nonylbenzene sulfonate, 20 g of polyacrylate, and 90% purity of purity, at normal temperature, stirring speed 300R / min is stirred in the configuration groove. 2H, a total of 1000 g of water treatment agents were obtained. It adds to the P507 nickel cobalt separation extraction device, and the amount of dose is 10 ppm (i.e., 10,000 dose flows is 10,000), and the agent is added to the feed tube in the feed tube. The P507 nickel cobalt separation process is two-stage saponified, 11th grade extraction, six-stage substando, tertiary washing, material liquid is a metal sulfate solution such as nickel, cobalt, calcium, and magnesium, and the pharmaceutical strabraride enters the extraction level. The extracted tank is then extracted from the extraction of the 11th level. The organic phase uses sodium carbonate soap-saponation to control the pH of the extract from 4 to 5, and the saponi...

Embodiment 2

[0032]Add 940 g of deionized water to the configuration slot, then sequentially add sodium nonylbenzene sulfonate, 20 g of polyacrylate, 20 g of polyacrylate, purity 30g, at normal temperature, stirring speed 300R / min is stirred for 2 h Further, a total of 1000 g of a water treatment agent is obtained. It was added to the P204 zinc extraction device, and the dose of 20 ppm was added, and the agent was added in the feed tube in the feed tube. The P204 zinc extraction process is two-stage saponified, six-stage extraction, four-stage substance, secondary washing, zinc extraction process, and various steps. The material is a metal sulfate solution containing zinc, iron, calcium, magnesium, manganese, and the drug accumulation liquid into the extract level, and then flows out of the extract from the extraction hexa random liquid. The organic phase P204 extractant concentration is 25% volume concentration, the saponification is 65%, using ammonia water saponified, the organic flow is ...

Embodiment 3

[0034] 870 g of deionized water was added to the configuration slot, and then sodium nonylbenzene sulfonate 10g, polyteenine 30g, 80 ml of concentrated sulfuric acid, stirred at normal temperature, stirring speed 300r / min, stirred for 2 h, obtained Total water treatment agents. It adds to a Versatic 10 nickel extraction device, and the dose of 5 ppm is added, and the agent is added to the feed tube in the feed tube. The VERSATIC10 extraction process is two-stage saponified, four-stage extraction, trilaterability, secondary washing, material liquid is a synthetic sulfate solution containing nickel, cobalt, iron, calcium, and magnesium ions, and the pharmaceutical strab is entered the extraction level. The extracted box is then applied from the extraction of the fourth stage. The organic versatic 10 extractant concentration is 25% volume concentration, the degree of saponification is 60%, using ammonia water saponification, and the organic flow is 1 l / min. Substrate flow rate 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com