Method for preparing directly soaking reaction type foamed nickel-graphene three-dimensional porous electrode

A three-dimensional porous, nickel foam technology, applied in electrode manufacturing, battery electrodes, hybrid/electric double-layer capacitor manufacturing, etc., can solve problems such as limiting process quality controllability, complex preparation procedures and high temperature environments, and increasing material manufacturing costs. Achieve low cost, improve reaction speed and product characteristics, and increase specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

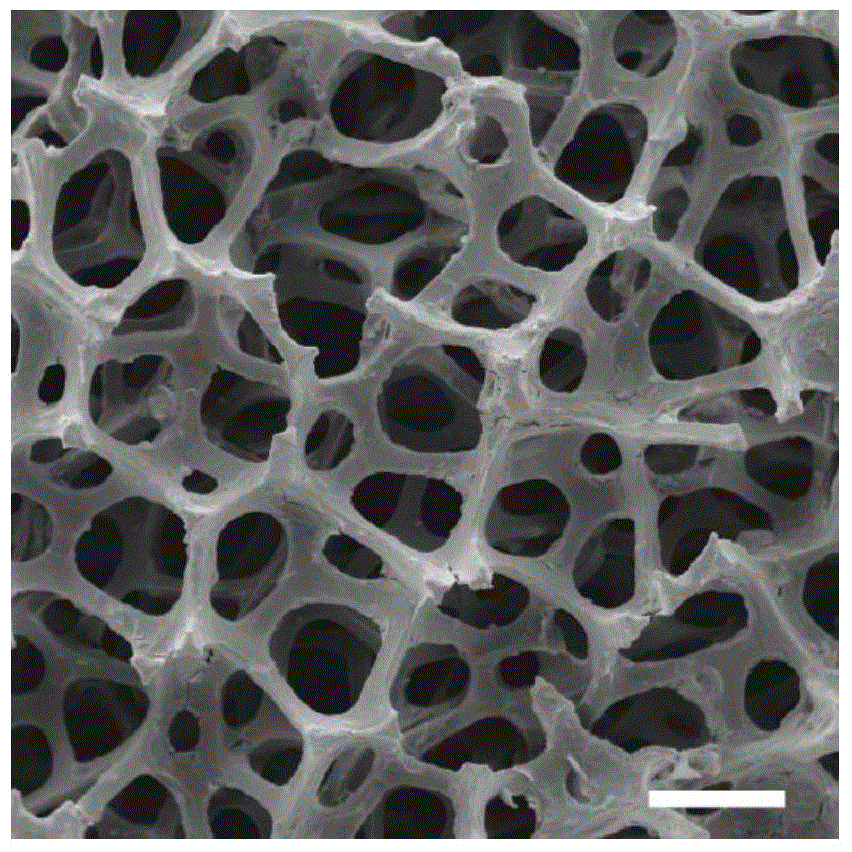

[0025] First, the nickel foam is cut into a size of, for example, 1cm (length) X 1cm (width) X 1mm (height), then washed with glacial acetic acid, acetone and ethanol, then washed with deionized water for about 5 minutes and then dried place;

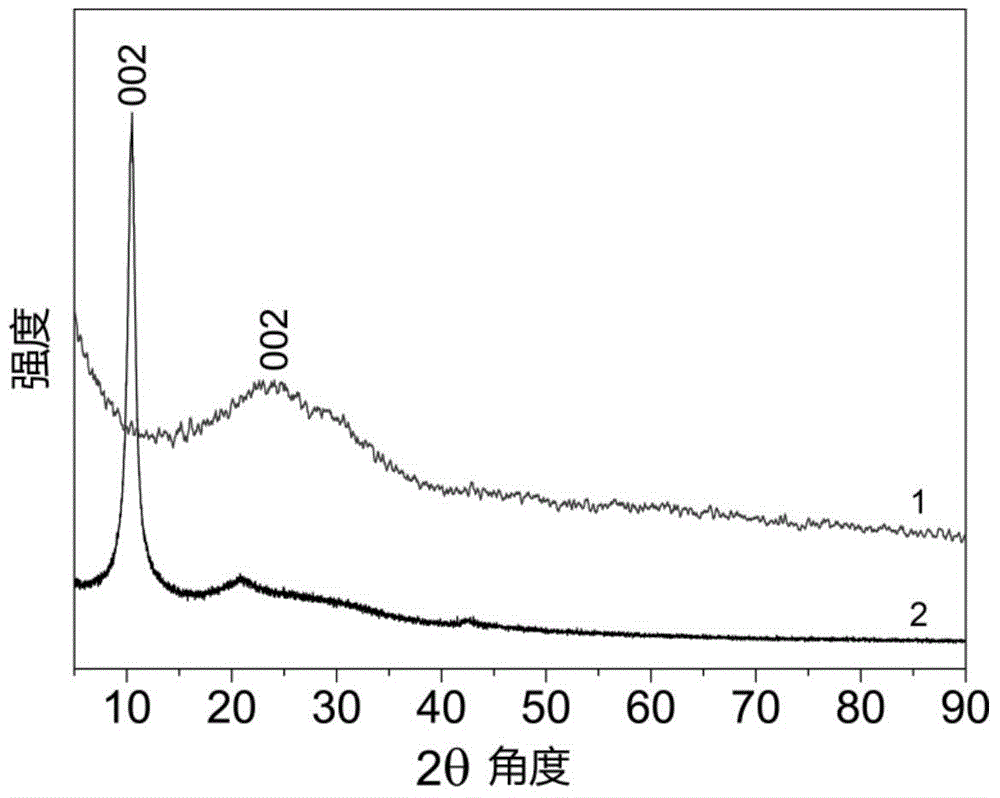

[0026] Then, preferably adopting oxidation peeling method (Hummers method) to prepare the graphene oxide aqueous solution that mass concentration is 0.5mg / mL~10mg / mL, and its concrete process is as follows: get 1g natural flake graphite powder, mix it with 23mL vitriol oil and 0.5mg / mL g of sodium nitrate was stirred and mixed in an ice bath, then slowly added 3 g of potassium permanganate to the solution, stirred for 2 hours, raised the temperature to 35 degrees, continued stirring for 2 hours, slowly added 46 mL of deionized water, Then the temperature was further raised to 95 degrees and maintained for 30 minutes, then about 100 mL of deionized water was added to the solution, the temperature was adjusted to normal temperature, 2 mL ...

Embodiment 2

[0030] First, the nickel foam is cut into a size of, for example, 1cm (length) X 1cm (width) X 1mm (height), then washed with glacial acetic acid, acetone and ethanol, then washed with deionized water for 5 minutes and then left to dry ;

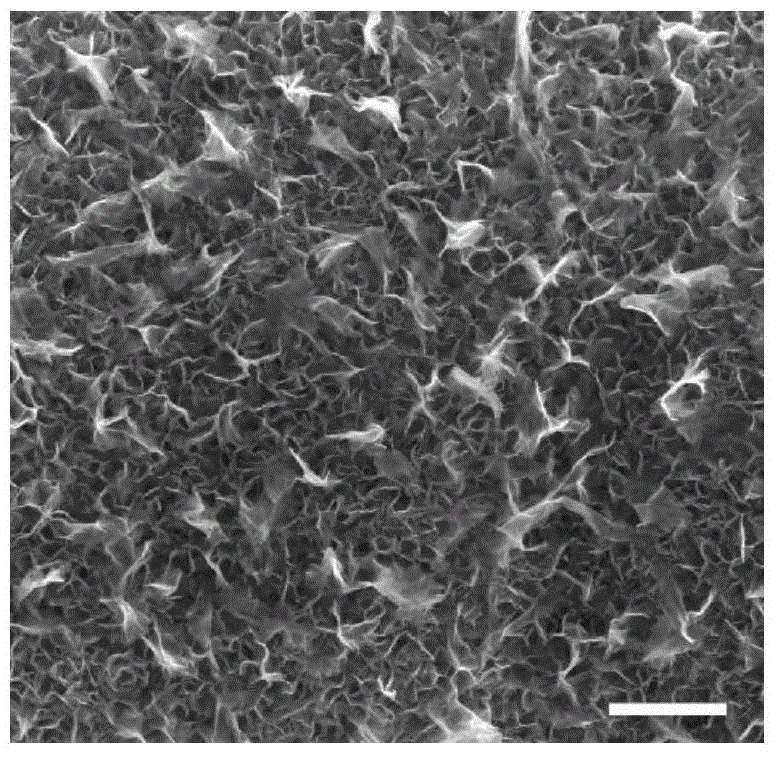

[0031]Next, it is preferable to use the oxidation stripping method (Hummers method) to prepare the graphene oxide aqueous solution, and adjust its key parameters to a mass concentration of 0.5 mg / mL, and then directly soak the nickel foam after the cleaning treatment. The reaction temperature was controlled to be 80 °C, and the soaking time was 2 hours. During this process, the nickel foam as the substrate directly reduced graphene oxide during soaking, and deposited and grown graphene on the surface of the nickel foam, which was taken out after the reaction. Foam nickel, and wash the surface with deionized water to form a three-dimensional porous nickel foam-graphene product.

Embodiment 3

[0033] First, the nickel foam is cut into a size of, for example, 1cm (length) X 1cm (width) X 1mm (height), then washed with glacial acetic acid, acetone and ethanol, then washed with deionized water for 5 minutes and then left to dry ;

[0034] Next, it is preferable to use the oxidation stripping method (Hummers method) to prepare the graphene oxide aqueous solution, and adjust its key parameter to a mass concentration of 5 mg / mL, and then directly soak the nickel foam after the cleaning treatment. The reaction temperature was controlled at 30 °C, and the soaking time was 6 hours. During the process, the nickel foam as the substrate directly reduced graphene oxide during soaking, and deposited and grown graphene on the surface of the nickel foam. After the reaction, the foam was taken out. Ni, and washed the surface with deionized water to form a three-dimensional porous nickel-graphene foam product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com