Benzoxazine monomer, benzoxazine precursor and low-dielectric benzoxazine resin

A benzoxazine and precursor technology, which is applied in the field of silicon-containing benzoxazine resins, can solve the problems of micro-phase separation of materials and damage to mechanical properties, unsuitable for industrial applications, uneven dispersion of components, etc., and achieves good toughness. , the effect of stable intermediate products and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for preparing a silicon-containing benzoxazine monomer, comprising the following steps:

[0052] In a reaction vessel with a stirrer and a thermometer, load 150ml of solvent chloroform, 24.03g (0.8mol) of paraformaldehyde and 44.2g (0.4mol), 3-aminopropyltriethoxysilane (KH550), and react at 40°C 1 hour. Then, 22.8 g (0.1 mol) of bisphenol A was added to the reaction mixture, and the temperature was raised to 85° C. and refluxed for 4 h under rapid stirring. After the reaction was completed, the insoluble matter was removed by filtration to obtain a yellow-green liquid. The solvent is distilled off under reduced pressure to obtain a bisphenol A benzoxazine monomer containing a silane coupling agent. 63 g of the monomer was obtained, and the yield was 80.7%. The silsesquioxane is a yellow-green viscous fluid (viscosity 2986 Nepal).

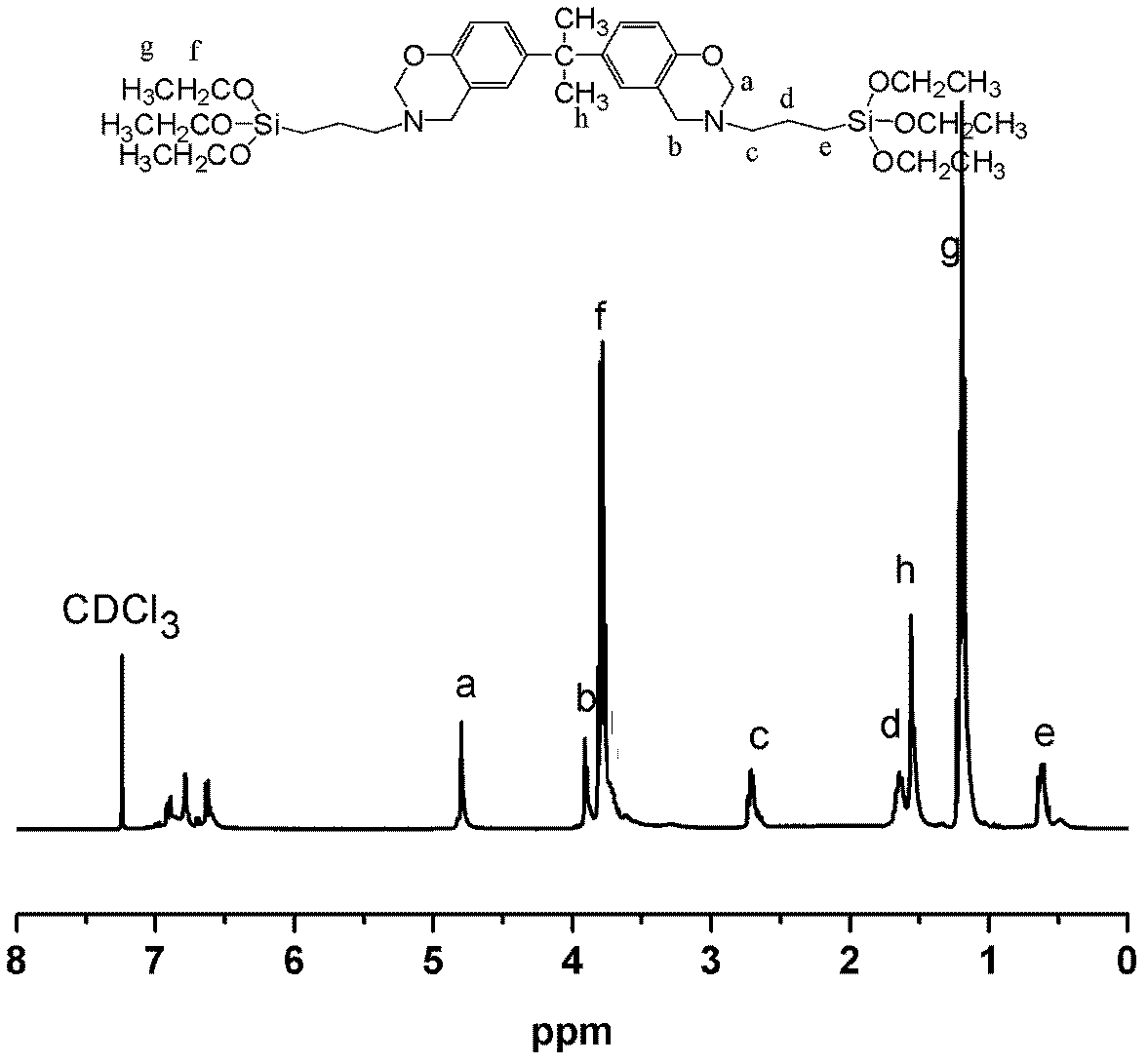

[0053] The H NMR spectra of the above products are as follows: figure 1 As shown, 4.81(a) and 3.92(b) in the figure are the c...

Embodiment 2

[0062] A method for preparing a silicon-containing benzoxazine monomer, comprising the following steps:

[0063] In a reaction vessel with a stirrer and a thermometer, load 150ml of solvent chloroform, 24.03g (0.8mol) of paraformaldehyde and 44.2g (0.4mol), 3-aminopropyltriethoxysilane (KH550), and react at 40°C 1 hour. Then, 35.5 g (0.1 mol) of bisphenol fluorene was added to the reaction mixture, and the temperature was raised to 85° C. and refluxed for 4 h under rapid stirring. After the reaction was completed, the insoluble matter was removed by filtration to obtain a yellow-green liquid. The solvent is distilled off under reduced pressure to obtain a product which is a bisphenol A benzoxazine monomer containing a silane coupling agent. 78 g of the monomer was obtained with a yield of 84.7%. The silsesquioxane is a yellow-green viscous fluid (viscosity 2986 Nepal).

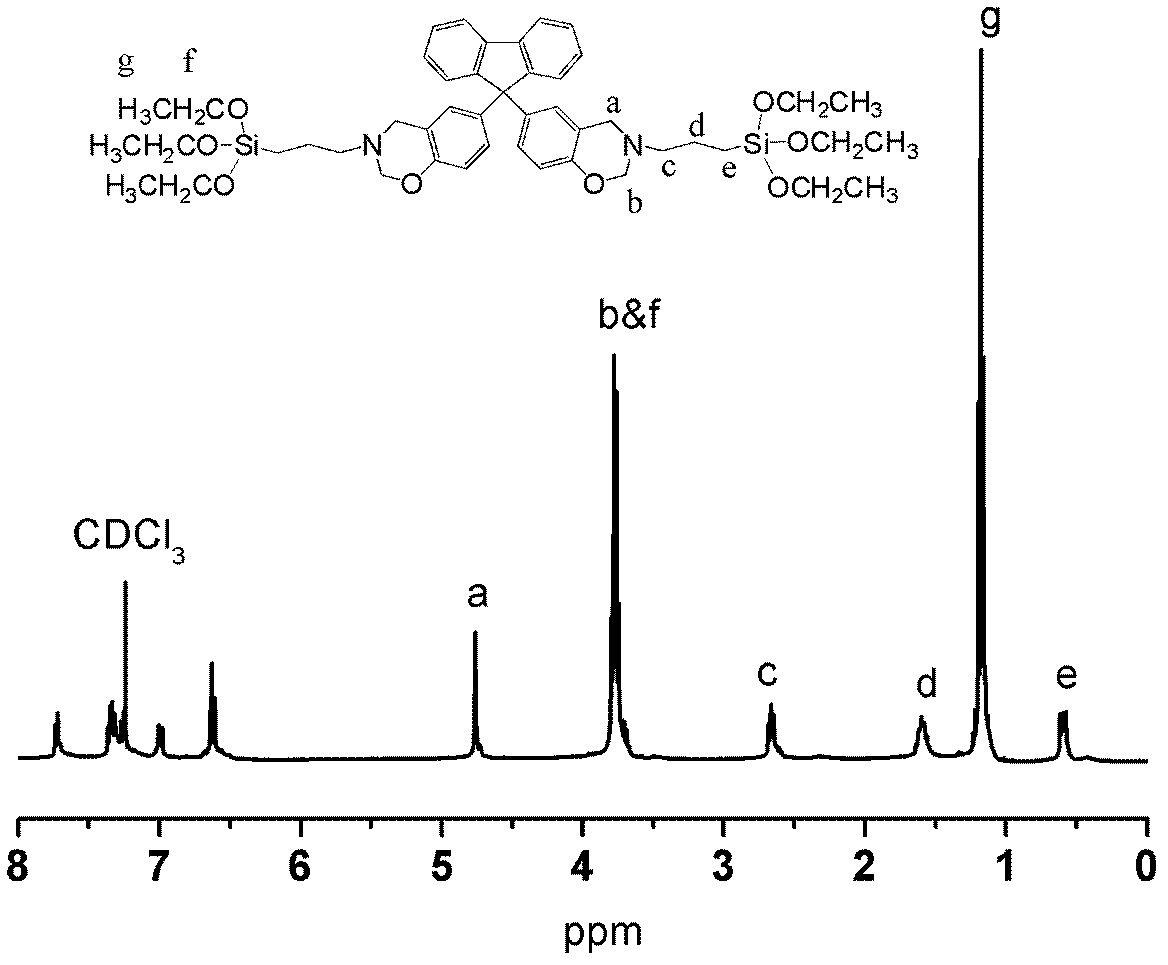

[0064] The H NMR spectra of the above products, such as figure 2 As shown, 4.82(a) and 3.83(b) in the...

Embodiment 3

[0073] A method for preparing a silicon-containing benzoxazine monomer, comprising the following steps:

[0074] In a reaction vessel with a stirrer and a thermometer, load 150ml of solvent chloroform, 24.03g (0.8mol) of paraformaldehyde and 44.2g (0.4mol), 3-aminopropyltriethoxysilane (KH550), and react at 40°C 1 hour. Then, 18.8 g (0.2 mol) of phenol was added to the reaction mixture, and the temperature was raised to 85° C. and refluxed for 4 h under rapid stirring. After the reaction was completed, the insoluble matter was removed by filtration to obtain a yellow-green liquid. The solvent is distilled off under reduced pressure to obtain a product that is a phenolic benzoxazine monomer containing a silane coupling agent. 63 g of the monomer was obtained, and the yield was 80.7%. The silsesquioxane is a yellow-green viscous fluid (viscosity 2986 Nepal).

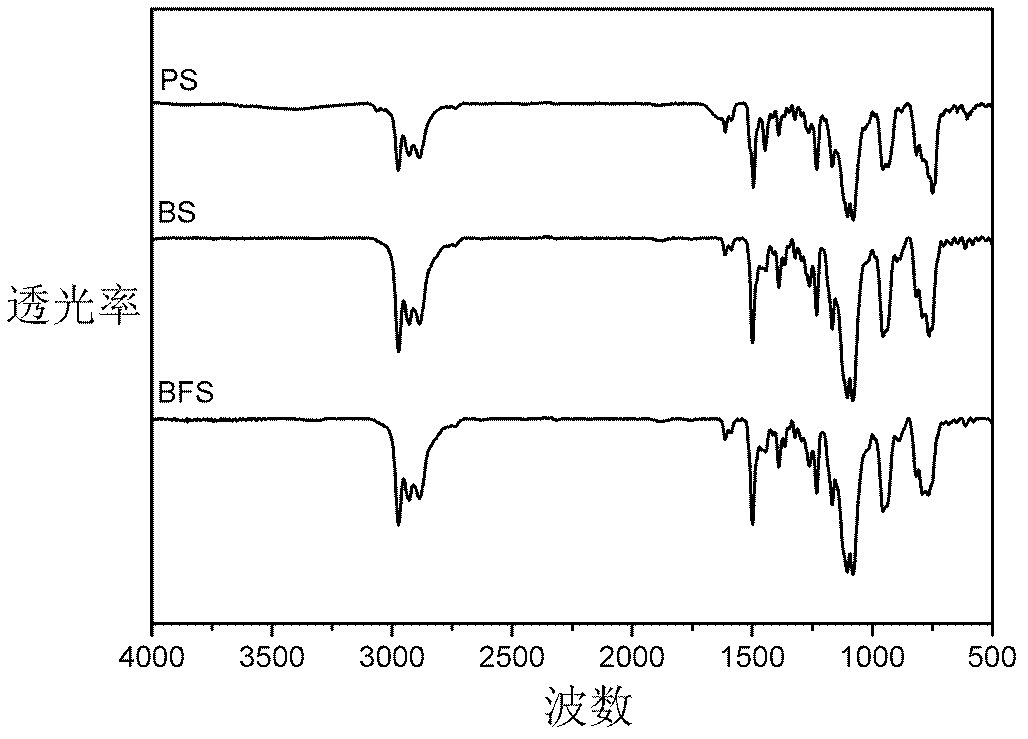

[0075] The infrared spectrum of the above product is as follows image 3 shown. From image 3 Medium, 1234cm - a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com