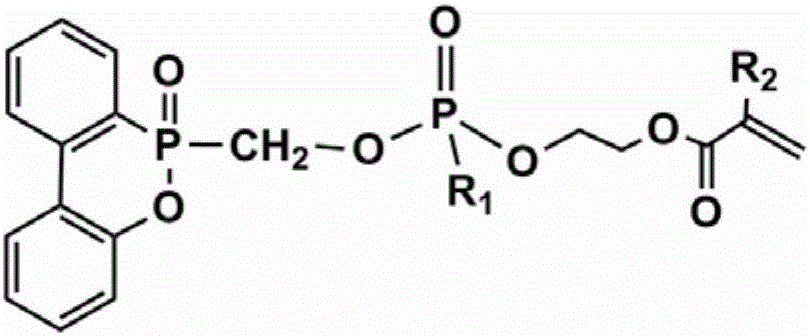

DOPO-based flame retardant, and preparation method thereof

A technology of flame retardant and solvent, which is applied in the field of DOPO-based flame retardant and its preparation, can solve the problems of large amount of flame retardant added, achieve good flame retardant effect, improve flame retardant performance, high purity and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

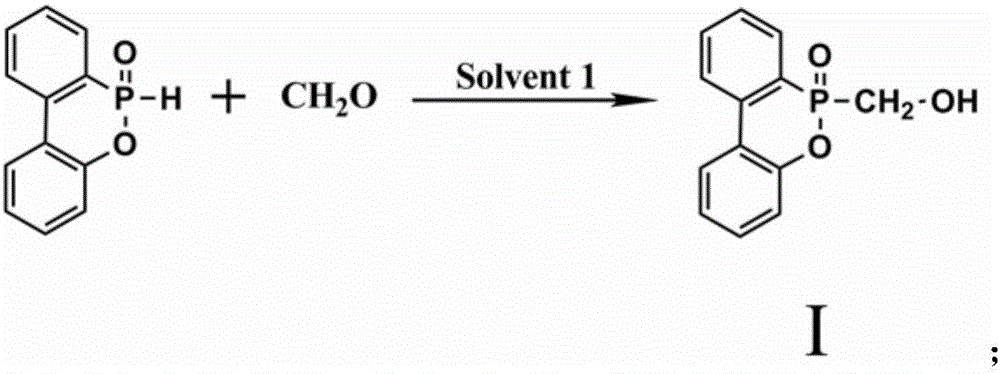

[0044]In the first step, add 0.5mol (108g) DOPO (9,10-di Hydrogen-9-oxa-10-phosphaphenanthrene-10-oxide) and 200mL toluene, stirred and heated to 80°C under nitrogen protection, after stirring until DOPO was completely dissolved, added 15g of paraformaldehyde, and then heated to Reflux reaction at 95°C for 8 hours, white precipitate will be produced during the reaction. When the reaction was complete, the reaction was stopped, and the precipitate was filtered and washed with toluene and vacuum-dried at 70° C. for 10 h to obtain dry product I.

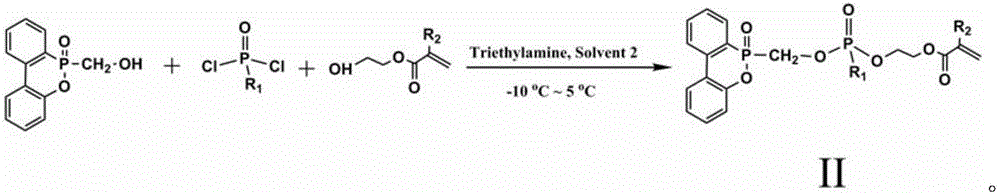

[0045] In the second step, phenyl dichlorinated phosphate (PDCP) (21.1g, 0.1mol) and 80mL tetrahydrofuran (THF) were added into a 250mL three-necked flask equipped with a mechanical stirrer, and the temperature of the system was controlled at 0°C; Triethylamine (TEA) (21.3g, 0.21mol) was added to the system; then hydroxyethyl acrylate (HEA) (11.6g, 0.1mol) and 20mL THF were added dropwise, and the process continued for 2 hours; after t...

Embodiment 2

[0049] In the first step, add 0.5mol (108g) DOPO and 200mL toluene to a 500mL three-necked flask equipped with a thermometer, a nitrogen inlet tube and a reflux condenser (the tail end is connected to an anhydrous calcium chloride drying tube), and the Under protection, stir and heat up to 75°C. After stirring until DOPO is completely dissolved, add 15g of paraformaldehyde, then heat up to 90°C and reflux for 10 hours. White precipitate will appear during the reaction. When the reaction was complete, the reaction was stopped, and the precipitate was filtered and washed with toluene and vacuum-dried at 80° C. for 10 h to obtain dry product I.

[0050] In the second step, phenyl dichlorinated phosphate (PDCP) (21.1g, 0.1mol) and 80mL of dichloromethane were added into a 250mL three-necked flask equipped with a mechanical stirrer, and the temperature of the system was controlled at -10°C; Add triethylamine (TEA) (21.3g, 0.21mol) in the system; Then drop into hydroxyethyl methacry...

Embodiment 3

[0054] In the first step, add 0.5mol (108g) DOPO and 200mL toluene to a 500mL three-necked flask equipped with a thermometer, a nitrogen inlet tube and a reflux condenser (the tail end is connected to an anhydrous calcium chloride drying tube), and the Under protection, stir and heat up to 80°C. After stirring until DOPO is completely dissolved, add 15g of paraformaldehyde, then heat up to 95°C and reflux for 8 hours. White precipitate will appear during the reaction. When the reaction was complete, the reaction was stopped, and the precipitate was filtered and washed with toluene and vacuum-dried at 70° C. for 12 h to obtain dry product I.

[0055] In the second step, add phenyl dichlorinated phosphate (PDCP) (21.1g, 0.1mol) and 80mL chloroform into a 250mL three-necked flask equipped with a mechanical stirrer, and control the temperature of the system at 5°C; after 30 minutes, add Triethylamine (TEA) (21.3g, 0.21mol); Add hydroxyethyl acrylate (HEA) (11.6g, 0.1mol) and 20mL ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com