Preparation method of polyacrylate levelling agent active matters for powdery paints

A technology of polyacrylates and acrylates, applied in powder coatings, coatings, etc., can solve the problems of insignificant dispersion and masking, improve recoating performance and appearance, anti-interference effect, and simplify the color change process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

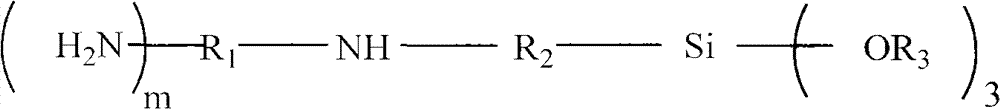

Method used

Image

Examples

preparation Embodiment 1

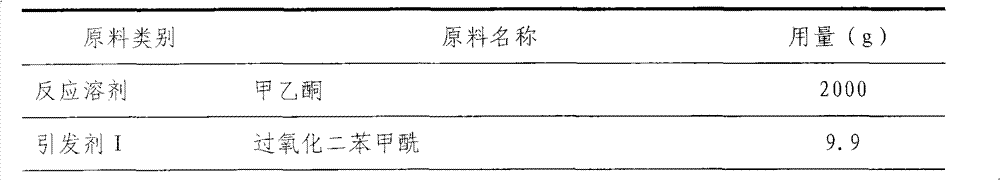

[0028] Table 1

[0029]

[0030]

[0031] The reaction materials and proportioning ratio are shown in Table 1. Proceed as follows:

[0032] (1) In a four-neck flask with a reflux condenser, a thermometer, a stirrer, and a dropping funnel, add the reaction solvent, start the stirrer, fill with nitrogen for protection, and heat up to solvent reflux (about 80°C);

[0033] (2) under reflux temperature, mixed monomer and initiator 1 are added dropwise in the flask, and 6h is dripped;

[0034] (3) Initiator II is supplemented in the flask, 10min is added, and then insulation reflux reaction 1.5h;

[0035] (4) Continue to maintain reflux, add the modifier dropwise to the reactor, drop it for 2.5 hours, and then continue to insulate for 2.5 hours;

[0036] (5) Distill under reduced pressure to remove the solvent, discharge and cool to obtain the leveling agent active substance A, which has a number average molecular weight of 9400 and a calculated Tg value of about -54.0°C. ...

preparation Embodiment 2

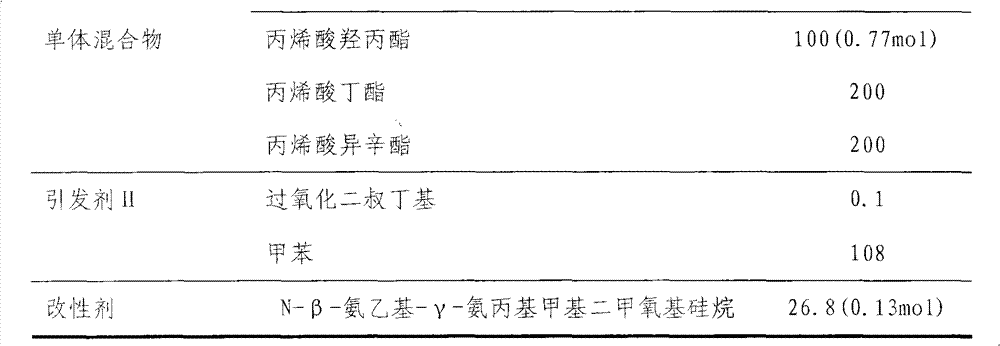

[0038] Table 2

[0039]

[0040]

[0041] The reaction materials and proportioning ratio are shown in Table 2. Proceed as follows:

[0042] (1) In a four-necked flask with a reflux condenser, a thermometer, a stirrer, and a dropping funnel, add the reaction solvent, start the stirrer, fill with nitrogen for protection, and heat up to solvent reflux (about 150°C);

[0043] (2) under reflux temperature, mixed monomer and initiator 1 are added dropwise in the flask, and 2h drops completely;

[0044] (3) Initiator II is supplemented in the flask, 60min is added, and then insulation reflux reaction 0.5h;

[0045] (4) Continue to maintain reflux, add the modifier dropwise to the reactor, drop it for 0.5h, and then continue to insulate for 0.5h;

[0046] (5) The solvent was removed by distillation under reduced pressure, and the leveling agent active substance B was obtained by discharging and cooling. The number average molecular weight was 7600 after testing, and the calcu...

preparation Embodiment 3

[0048] table 3

[0049]

[0050] The reaction materials and proportioning ratio are shown in Table 3. Proceed as follows:

[0051] (1) In a four-neck flask with a reflux condenser, a thermometer, a stirrer, and a dropping funnel, add the reaction solvent, start the stirrer, fill with nitrogen for protection, and heat up to solvent reflux;

[0052] (2) under reflux temperature, mixed monomer and initiator 1 are added dropwise in the flask, and 3h is dripped;

[0053] (3) Initiator II is replenished in the flask, 30min has been added, then insulation reflux reaction 1h;

[0054] (4) Continue to maintain reflux, add the modifier dropwise to the reactor, drop it for 1h, and then continue to insulate for 2h;

[0055] (5) Distill under reduced pressure to remove the solvent, discharge and cool to obtain leveling agent active substance C, the number average molecular weight is 8100 after testing, and the calculated Tg value is about -51.3°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com