Preparation method of special material for fluorine-containing plastic film

A technology of plastic film and special material, applied in the field of fluoroplastic film, can solve the problems of water vapor barrier, low thermal shrinkage, unsuitable for large-scale promotion, high thermal shrinkage, and achieve low water vapor transmission rate, excellent weather resistance, Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

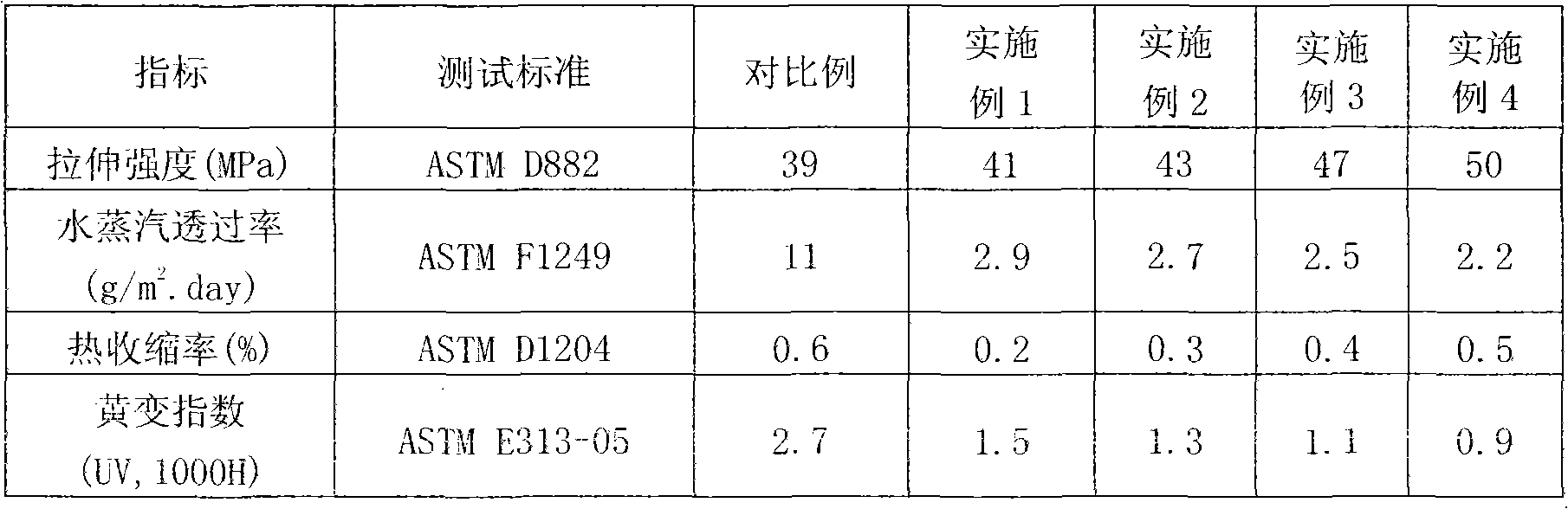

Examples

Embodiment Construction

[0015] The following implementation examples are to further illustrate the present invention, and the present invention is not limited to the following examples and implementation methods.

[0016] Examples 1, 2, 3, and 4 are four different special material formulas, listed in Table 1. The raw materials used in the embodiment are as follows:

[0017] Polyvinylidene fluoride (PVDF): SOLEF 1001, Solvay, USA

[0018] Polymethyl methacrylate (PMMA): 6N, Evonik

[0019] Titanium dioxide (Ti0 2 ): R-103, DuPont, USA

[0020] Calcium carbonate (CaCO 3 , Nanometer level): NPCC-201, Shanxi Ruicheng Xintai Nano Material Co., Ltd.

[0021] Dioctyl phthalate (DOP): Electrical grade DOP, Shandong Qilu Plasticizer Co., Ltd.

[0022] Heat stabilizer: antioxidant Irganox 1010, Ciba Chemical Co., Ltd.

[0023] The formulations of Examples 1 to 4 are shown in Table 1.

[0024] Table 1 Examples 1 to 4 formula (parts by weight: %)

[0025] raw material name

[0026] According to the formula in Table 1, wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com