Packaging polyolefin film and preparation method thereof

A polyolefin and film technology, applied in the field of polyolefin biaxially oriented film and its preparation, can solve the problems of poor physical and heat-sealing properties of PP stretched film, easy shrinkage, etc., and achieve excellent heat-sealing characteristics, low shrinkage rate, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

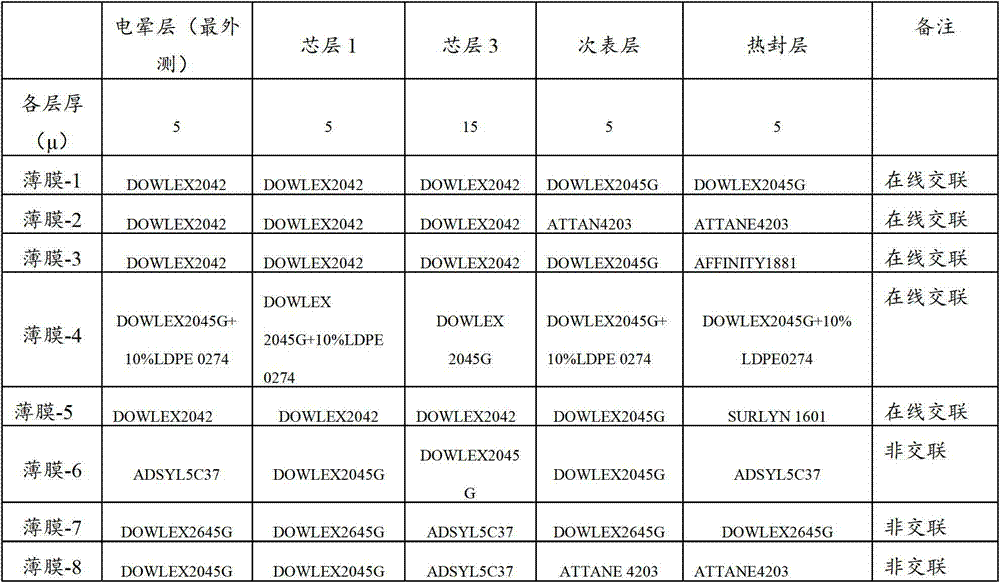

[0065] The BOPE stretched composite film is produced on a 5-layer co-extrusion tubular film biaxial stretching equipment, and its structure is shown in Table 1 below. Films 9 and 10 are PE films produced by conventional blow molding, and their structures are shown in Table 2.

[0066] The structure of the film (total thickness: 35 μ) of the present invention is shown in Table 1:

[0067] Table 1: Thin film structure of the present invention

[0068]

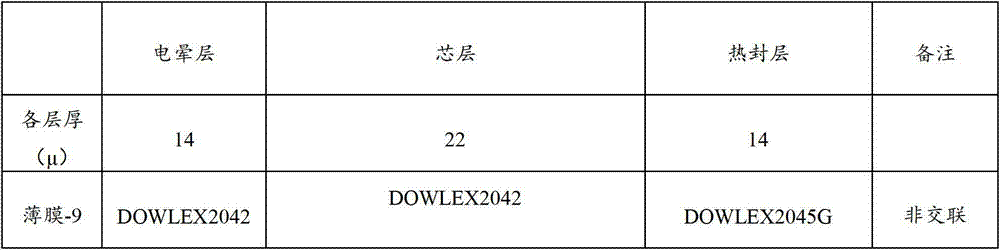

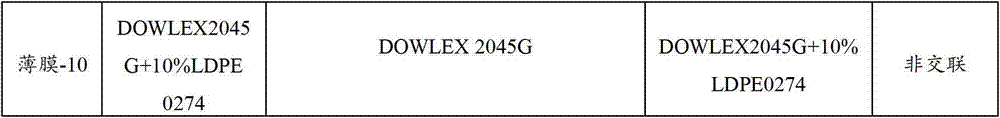

[0069] Table 2: Comparative film (total thickness: 50 microns) structure

[0070]

[0071]

[0072] The details of the materials used are shown in Table 3:

[0073] Table 3: Raw materials used

[0074]

[0075] The production of film 1-8 is produced on the production line of tubular film biaxial stretching process, and the specific process is as follows:

[0076] 1. Extrusion of polyolefin raw materials;

[0077] 2. Forming a circular first tube membrane through the ring head;

[0078] 3. The cooling water se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com