Material special for polyvinylidene fluoride film

A technology of polyvinylidene fluoride and special materials, which is applied in the field of special materials for polyvinylidene fluoride films, can solve problems such as unsuitable for large-scale promotion, high thermal shrinkage rate, low thermal shrinkage rate, etc., and achieve improved dimensional stability, high mechanical Effects of Strength and Low Thermal Shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

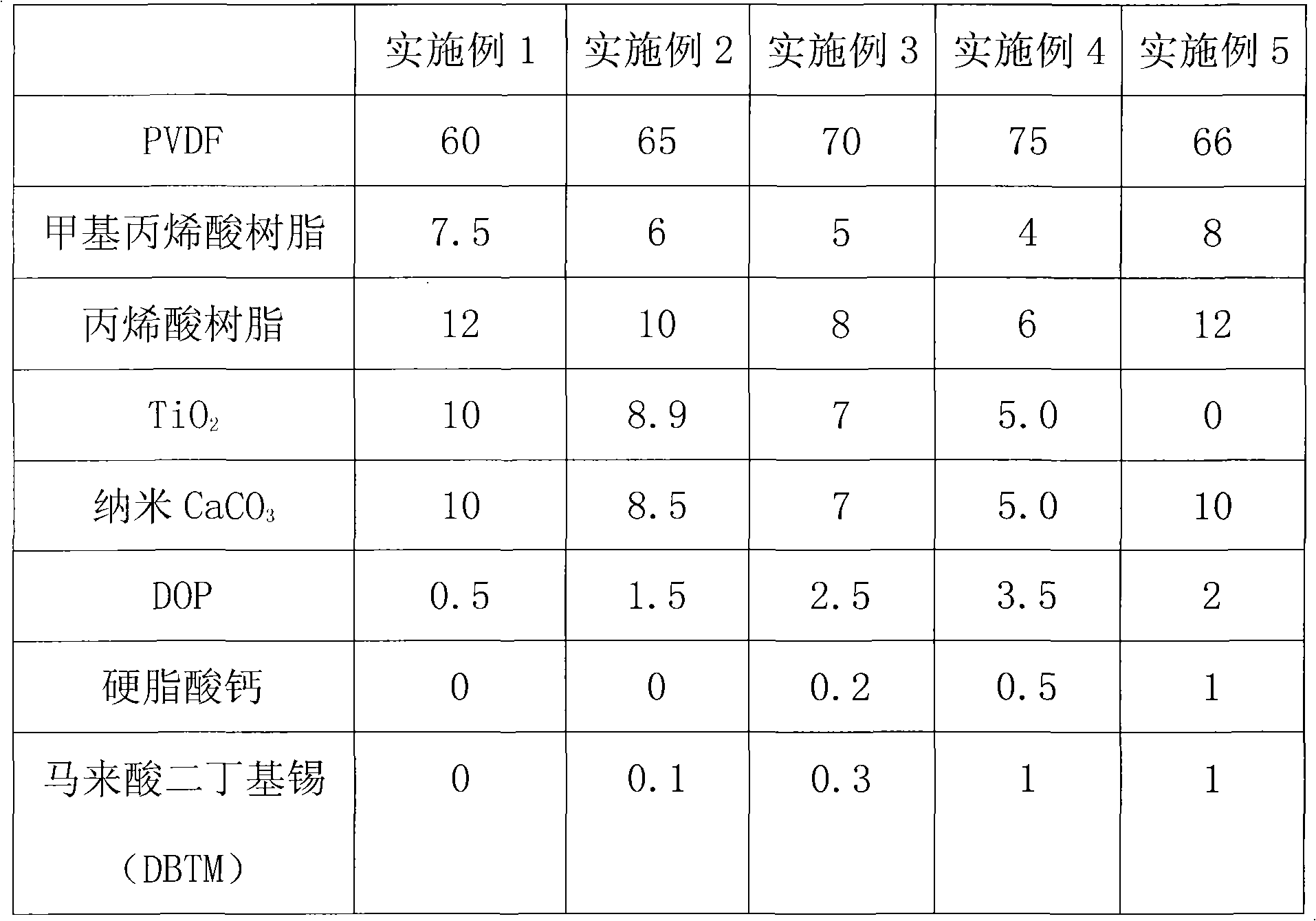

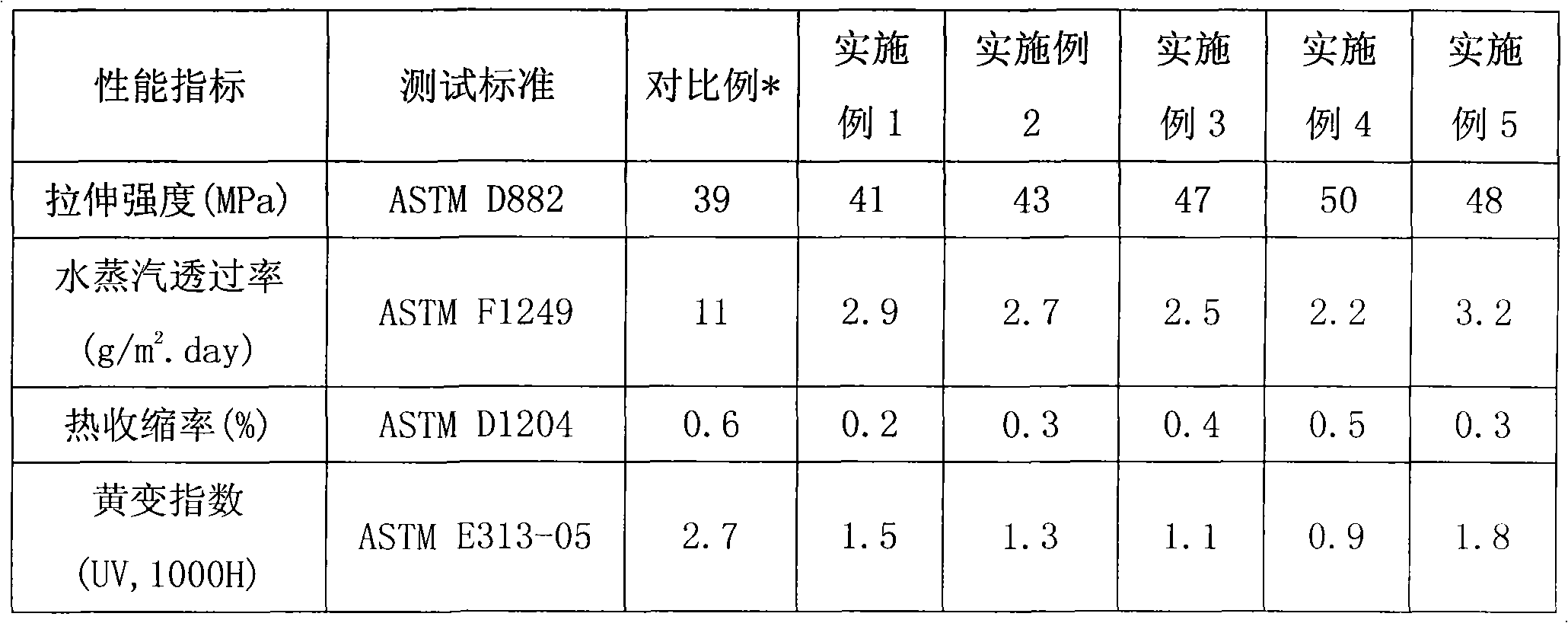

[0021] The following implementation examples are further descriptions of the present invention, but the present invention is not limited to the following examples and implementation methods.

[0022] When the molecular weight of polyvinylidene fluoride is between 200,000 and 1 million, the raw material can be plasticized and processed, and the mechanical properties of the film are excellent.

[0023] The fluidity modifier used in the present invention is any one or combination of any of phthalates and phosphates. Among them, the flow modifier of phthalates can be: dimethyl phthalate, diethyl phthalate, dibutyl phthalate, phthalate Dihexyl phthalate, dioctyl phthalate, diisooctyl phthalate, diisodecyl phthalate, bis(2-methyl phthalate) Hexyl ester), dicyclohexyl phthalate, etc.; the flow modifier of phosphate esters can be: triethyl phosphate, tributyl phosphate, trioctyl phosphate, etc.

[0024] The heat stabilizing aid used in the present invention is any one or a combinati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com