Composite diaphragm for lithium ion batteries, production method thereof, and lithium ion battery

A lithium-ion battery, composite diaphragm technology, applied in secondary batteries, battery pack parts, separators/films/diaphragms/spacers, etc. Problems such as direct contact between positive and negative electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

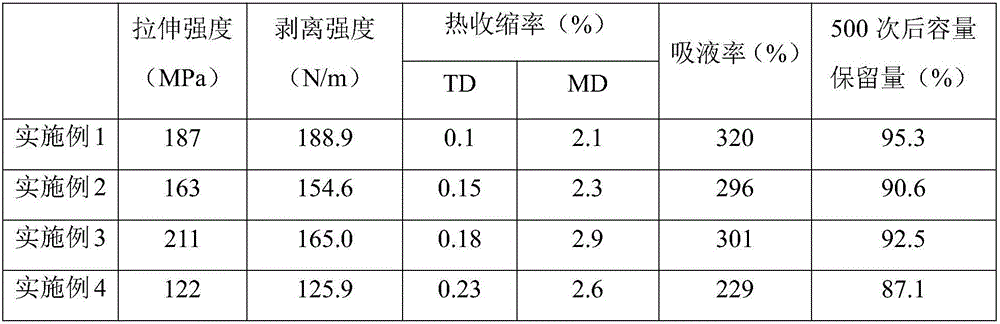

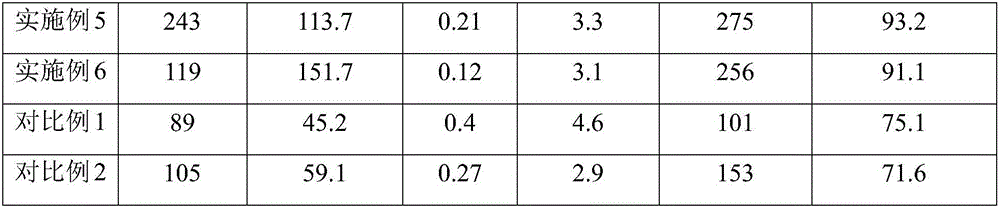

Examples

preparation example Construction

[0030] The present invention also provides a preparation method of a composite diaphragm for a lithium ion battery, comprising the following steps:

[0031] A. Carry out swelling treatment to cellulose, obtain swollen cellulose;

[0032] B. Mix the ceramic particles and ceramic whiskers in the dispersant evenly, then add swelling cellulose, add the binder after mixing evenly, and obtain the ceramic slurry after stirring evenly;

[0033] C. Coating the ceramic slurry on the surface of the polymer matrix, and drying to obtain a composite thin film for the lithium ion battery.

[0034] According to the present invention, the ceramic slurry is coated on the surface of the polymer matrix by a coating method, the coating speed is 5-100m / min, the drying temperature is 30-80°C, and the ceramic slurry coats the base film The thickness of the obtained ceramic coating is 0.1-50 μm.

[0035]According to the present invention, in step A, the swelling treatment step of the cellulose is: s...

Embodiment 1

[0044] A lithium ion battery is made up of positive pole, negative pole and diaphragm, and its preparation method is as follows:

[0045] (1) Preparation of positive electrode

[0046] 100 parts by weight of the positive electrode active material LiNi 0.33 co 0.33 mn 0.34 o 2 , 4 parts by weight of binder polyvinylidene fluoride (PVDF), 4 parts by weight of conductive agent acetylene black are added in 50 parts by weight of N-methylpyrrolidone (NMP), then stirred in a vacuum mixer to form a uniform positive electrode slurry ; Coat the slurry evenly on an aluminum foil with a width of 400mm and a thickness of 20μm, then dry it at 120°C, roll it under a pressure of 1.6MPa and cut it on a slitting machine to obtain a positive electrode with a size of 385mm×42mm×135μm , the dressing density of the obtained positive electrode sheet is 3.4g / cm 3 .

[0047] (2) Preparation of negative electrode

[0048] 100 parts by weight of negative electrode active material natural graphite...

Embodiment 2

[0056] A lithium ion battery is made up of positive pole, negative pole and diaphragm, and its preparation method is as follows:

[0057] (1) The preparation method of positive electrode is the same as embodiment 1;

[0058] (2) the preparation method of negative pole is with embodiment 1;

[0059] (3) Preparation of diaphragm:

[0060] A. Soak 1.5 parts by weight of cellulose in sodium hydroxide / urea aqueous solution (25° C.) for 5 hours, then filter to remove the filtrate, wash the filter residue with water until neutral, then ultrasonically disperse for 30 minutes, and filter to obtain swollen cellulose;

[0061] B, 9 parts by weight of magnesium oxide particles (average particle diameter is 10nm), 20 parts by weight of titanium dioxide particles (average particle diameter is 50nm), polyurethane spinning 0.72 parts by weight (average diameter is 100nm) and yttrium oxide crystal 5.8 parts by weight of whiskers (the average diameter is 100nm, and the average length is 2 μm)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com