Nontoxic, anti-heat shrinkable polyvinyl chloride material and manufacturing technology thereof

A polyvinyl chloride, manufacturing process technology, applied in the field of polymer material modification, to achieve good compatibility and stability, avoid stress concentration, overcome instability and extravasation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

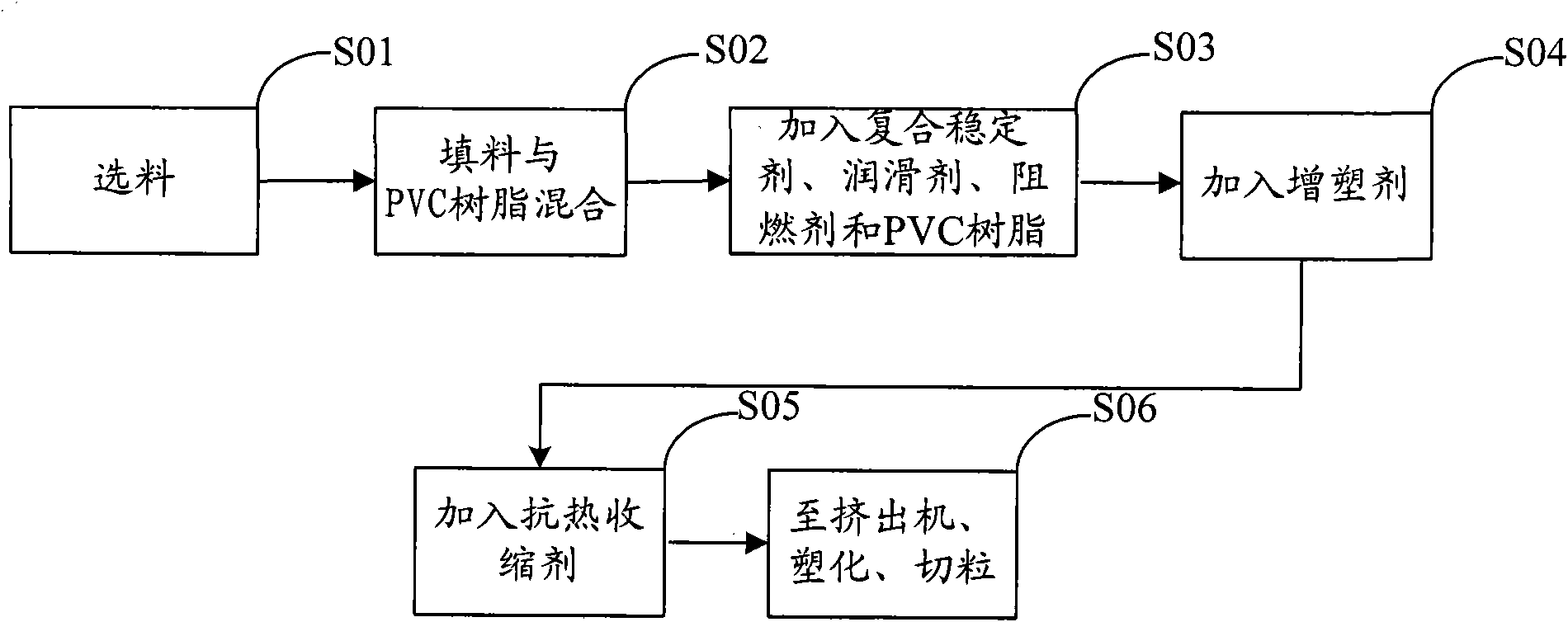

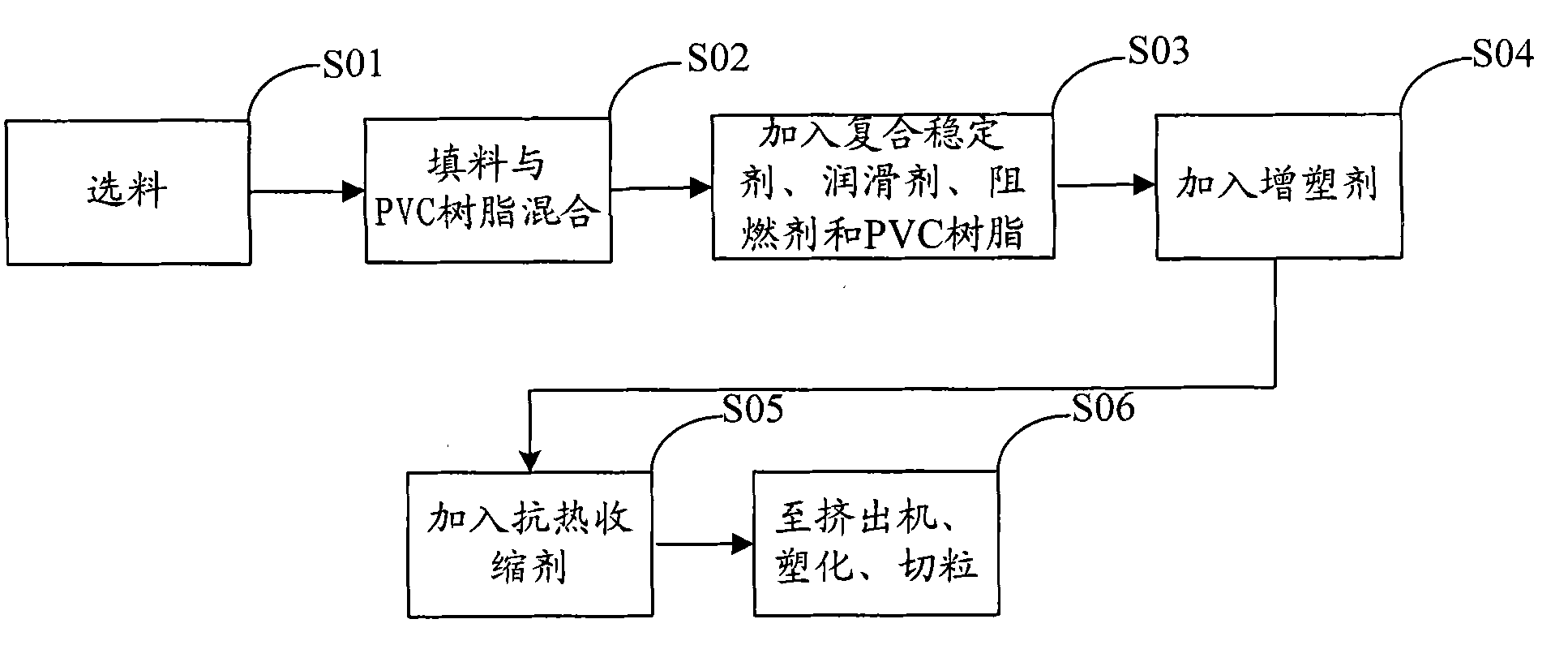

Method used

Image

Examples

Embodiment 1

[0065] The nontoxic, anti-shrinkage PVC material component and content thereof of the present embodiment are:

[0066] Polyvinyl chloride (PVC resin S-70, Ningbo Formosa Plastics) 100 parts;

[0067] Filler (calcium carbonate, Dongguan Meilitai) 25 parts;

[0068] Plasticizer (TOTM, PN-1013, Zhongshan Liancheng; soybean oil, Japan Mitsubishi) 50 parts;

[0069] Lubricant (OPE, stearic acid, Dongguan Kaiji) 1 part;

[0070] Foaming agent (AC foaming agent, i.e. azodicarbonamide) 0.5 parts;

[0071] Stabilizer (composite non-toxic high temperature resistant stabilizer, Japan ADK) 10 parts;

[0072] 8 parts of flame retardant (antimony trioxide, magnesium hydroxide, aluminum hydroxide, flashing star antimony industry);

[0073] 12 parts of anti-heat shrinkage agent (glass microspheres);

[0074] 1 part of dyeing agent (BASF, Germany).

[0075] The specific process of the manufacturing process of the nontoxic, heat-shrinkable PVC material of the present embodiment is as foll...

Embodiment 2

[0079] The nontoxic, anti-shrinkage PVC material component and content thereof of the present embodiment are:

[0080] Polyvinyl chloride (PVC resin TG-1300, Guangdong Tosoh) 100 parts;

[0081] 22 parts of filler (nanometer calcium carbonate);

[0082] Plasticizer (TOTM, Zhongshan Liancheng; soybean oil, Mitsubishi) 45 parts;

[0083] Lubricant (OPE, stearic acid, Dongguan Kaiji) 1 part;

[0084] Stabilizer (composite non-toxic high temperature resistant stabilizer, Japan ADK) 10 parts;

[0085] Flame retardant (antimony trioxide, magnesium hydroxide, aluminum hydroxide, flash star antimony industry) 10 parts;

[0086] 15 parts of anti-heat shrinkage agent (glass microspheres);

[0087] 1 part of dyeing agent (BASF, Germany).

[0088] The specific process of the manufacturing process of the nontoxic, heat-shrinkable PVC material of the present embodiment is as follows: add 22 kilograms of calcium carbonate powder in the high-speed mixer with 10,000 horsepower, then add 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com