Cooling fluid of engine

A technology of engine coolant and alkali metal salt, which is applied in the field of engine coolant, can solve the problems of limited use, cavitation corrosion, high production cost of all organic acid engine coolant, etc., and achieve the effect of reducing usage and large cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

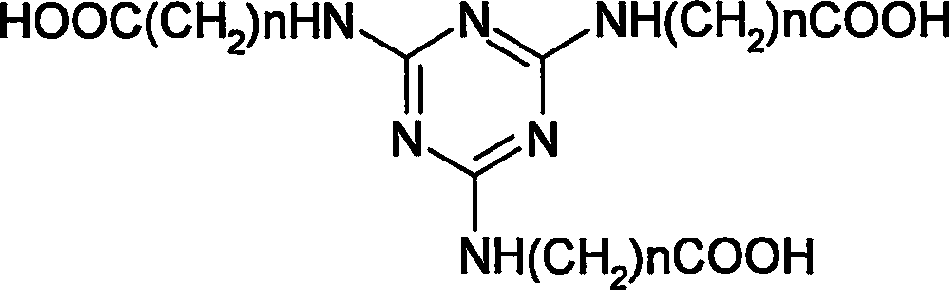

Method used

Image

Examples

Embodiment Construction

[0039] The cooling liquid formula of the present invention has been subjected to a large number of screening experiments, and a formula combination with reasonable economy and excellent technology has been obtained. The following table is 8 embodiment formulas:

[0040]

components

Content in formula %

1

2

3

4

5

6

7

8

ethylene glycol

92.5

92.3

93.0

65

58

53

45

39

Organic tripolycarboxylic acid

1.0

0.8

0.7

0.6

0.4

0.3

0.2

0.1

sodium adipate

0.2

0.3

0.4

0.6

0.8

1.0

Sodium pimelate

0.3

sodium suberate

0.3

0.5

0.8

1.0

1.2

1.5

Sodium Azelate

0.5

sodium sebacate

3.0

2.0

1.0

0.8

0.5

0.3

Potassium sebacate

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com