Perforating machine applied to preparation of medical dressings

A technology of punching machine and switching mechanism, which is applied in the direction of metal processing, etc. It can solve the problems that the continuous input and output of dressing cannot be realized through mechanical action, manual loading of dressing and discharging work, and low work efficiency, so as to achieve high drilling efficiency , simple structure, and the effect of improving output output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

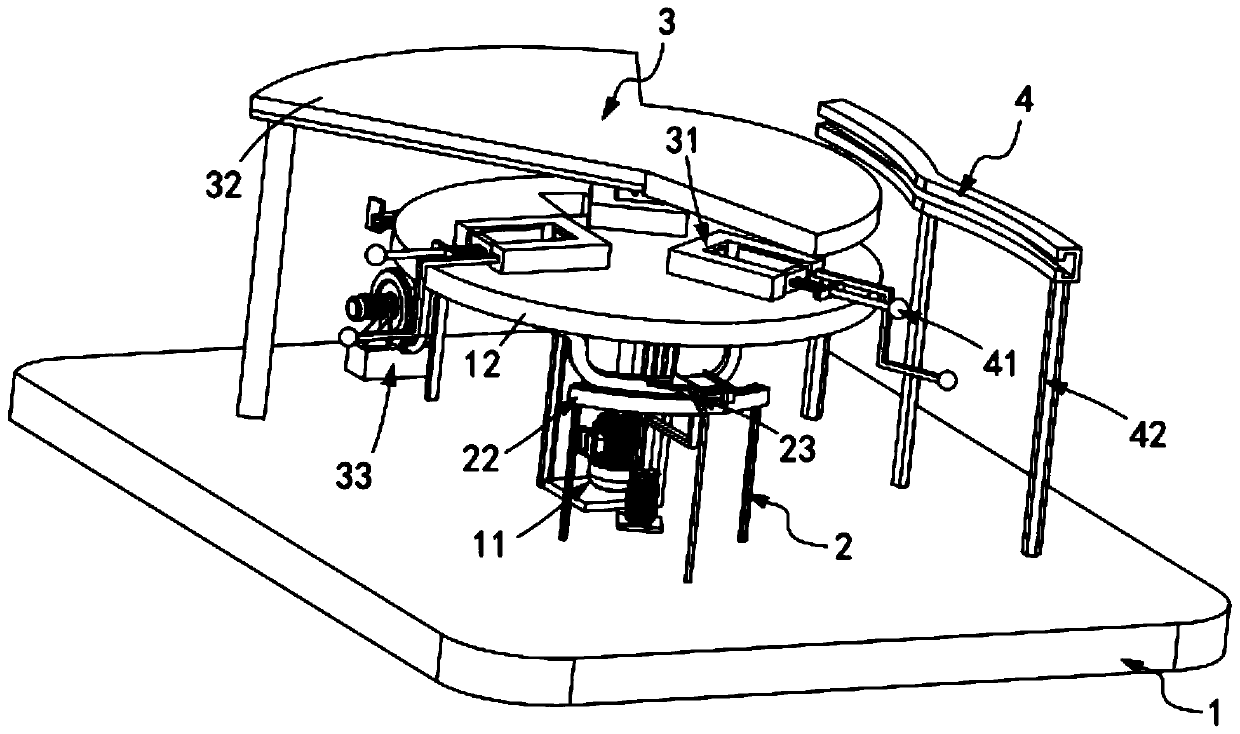

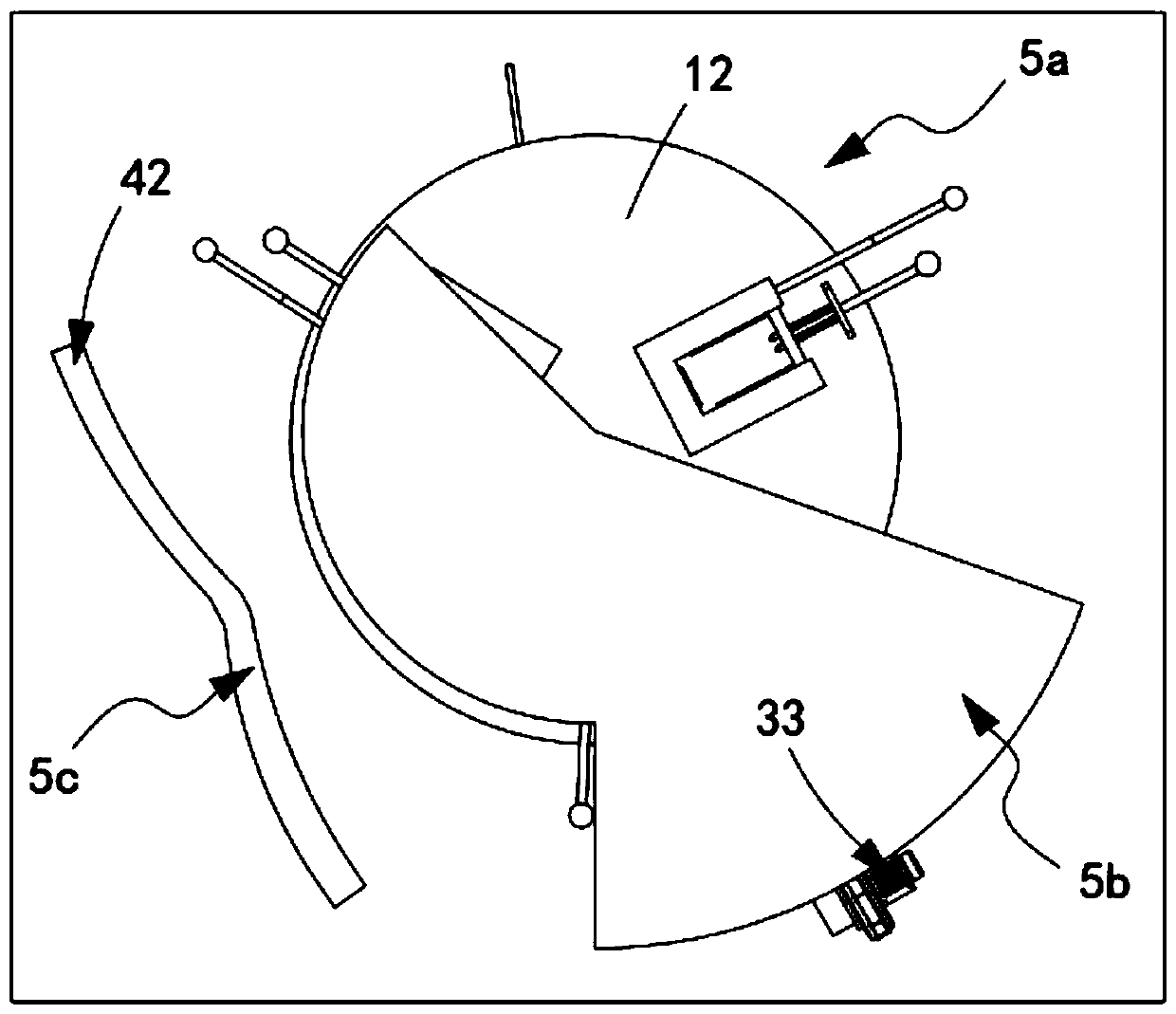

[0082] Such as figure 1 , figure 2 and Figure 23 As shown, a punching machine applied to the preparation of medical dressings, including:

[0083] A station switching mechanism 1, the station switching mechanism 1 includes a drive assembly 11 and a rotating disk 12 driven by the driving assembly 11 to rotate in a circle, and several groups of dressings and dressings are provided on the rotating disk 12 at equal intervals along its circumferential direction. 10 matching positioning slots 13;

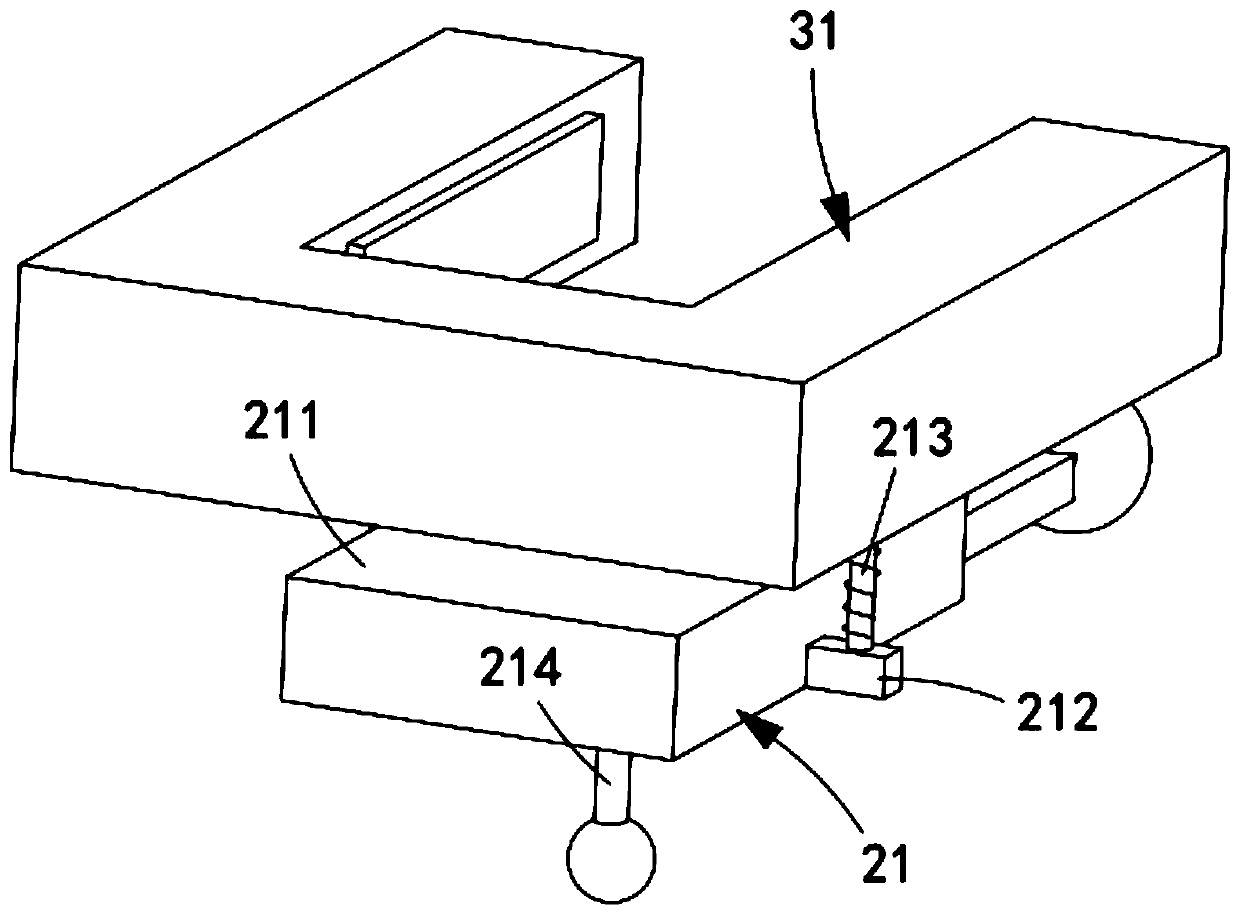

[0084] The dressing loading mechanism 2, the dressing loading mechanism 2 includes the lifting assembly 21 arranged under the rotating disk 12 and corresponding to the positioning groove 13 one by one, cooperates with the lifting assembly 21 and is arranged on the lifting assembly 21, the guide assembly 22 on the outer side, the feeding assembly 23 that cooperates with the guide assembly 22 to transmit the dressing to the lifting assembly 21, and is arranged corresponding to the outp...

Embodiment 2

[0133] Such as Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 and Figure 22 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0134] further, such as Figure 18 As shown, the punching assembly 41 includes:

[0135] The slider c411, the slider c411 is slidably arranged in the T-shaped groove 413 on the rotating disk 12 through the T-block 412;

[0136] Needle threading unit 414, the needle threading unit 414 is arranged in two groups at equal intervals along the length direction of the slider c411, which includes a thimble 415 penetrating through the slider c411 with its tip facing into the pressing assembly 31 and sleeved A spring 416 outside the thimble 415 and one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com