Full-automatic pipe mouth shaping machine for U-shaped copper pipe

A fully automatic, shaping machine technology, applied in the field of copper tube production equipment, can solve problems such as low shaping efficiency, and achieve the effects of improving shaping efficiency, increasing production output, and reducing personnel costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

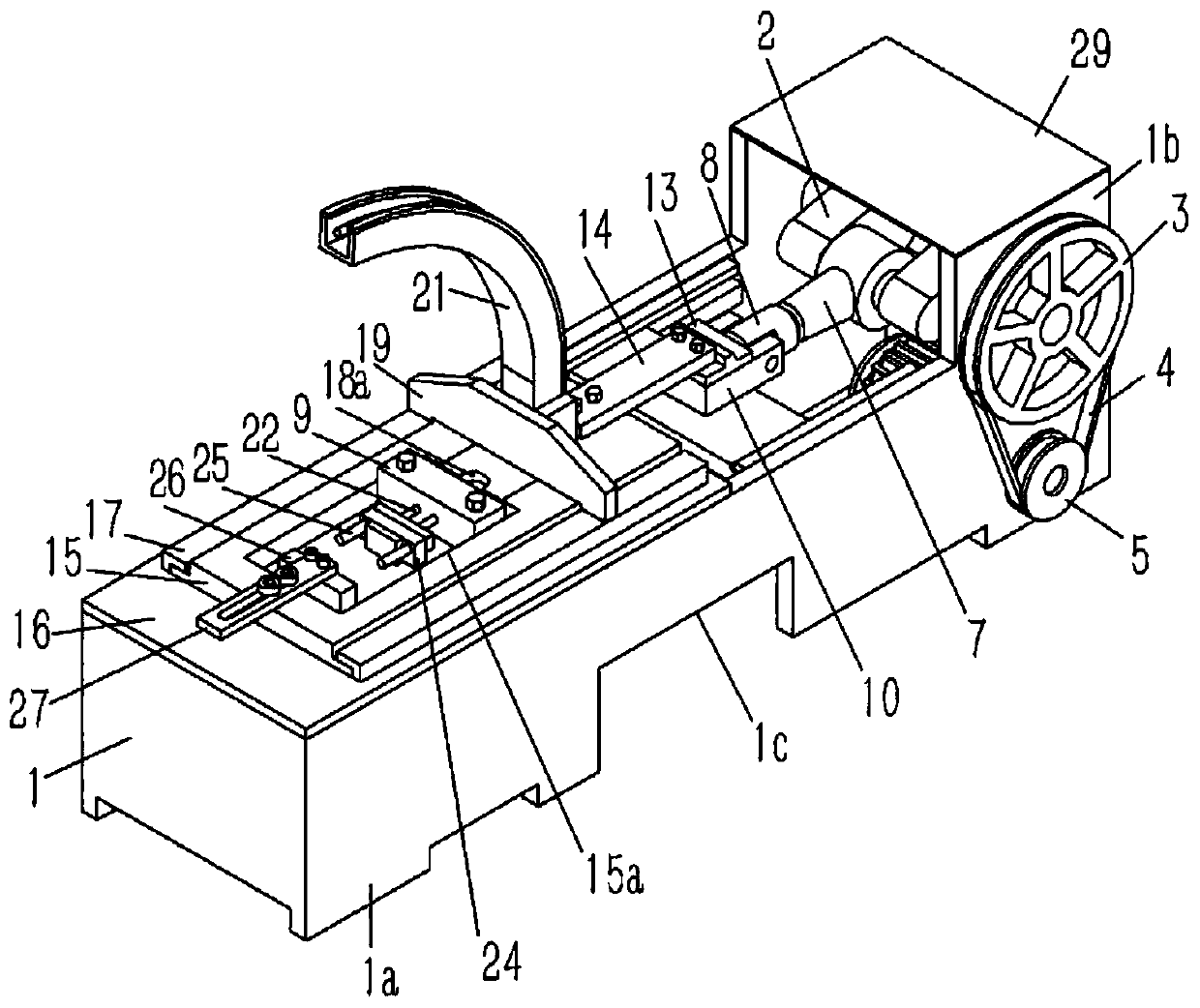

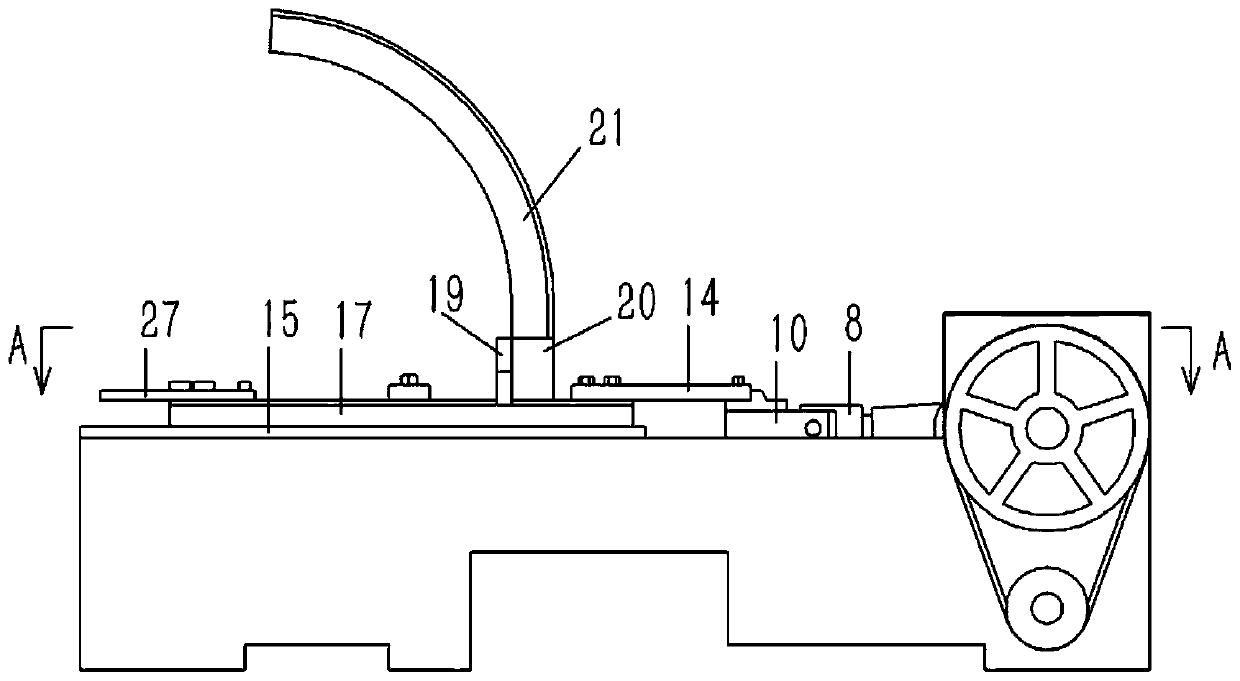

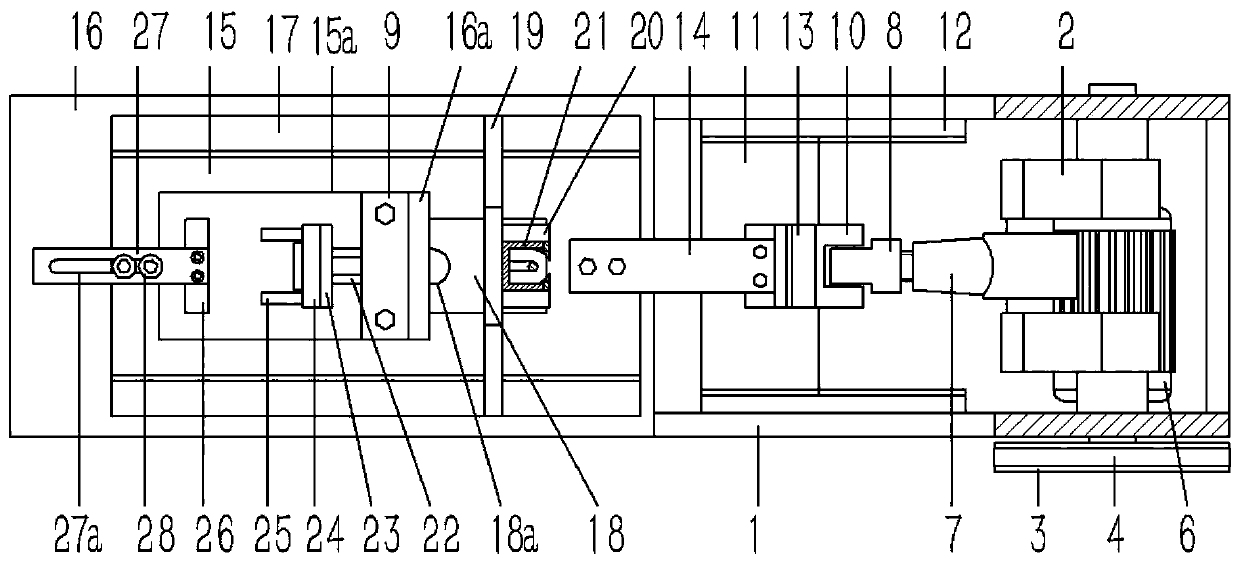

[0022] Example: see Figures 1 to 6 As shown, the U-shaped copper tube automatic nozzle shaping machine includes a frame 1. The frame 1 is composed of a rectangular frame. On the two side frames at the right end of the frame 1, an upwardly extending support plate 1b is formed. The support plate 1b There is a crankshaft 2 between them, and the two ends of the crankshaft 2 are hinged on the support plate 1b of the frame 1 through bearings, and one end of the crankshaft 2 passes through the support plate 1b to insert and fix the driven pulley 3, and the driven pulley 3 passes through the The transmission belt 4 is connected with the driving pulley 5, the driving pulley 5 is inserted and fixed on the rotating shaft of the motor 6, and the motor 6 is fixed on the frame 1;

[0023] The crankshaft 2 is hinged with a connecting rod 7, and the other end of the connecting rod 7 is fixedly connected with a connector 8, and the connector 8 is hinged to the sliding seat 10 through a hinge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com