Burr machining equipment for plastic shell of storage battery

A technology for processing equipment and batteries, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of reducing the fine finish of deburring work, unable to fix the positioning of the battery shell, etc., to improve the fast release effect, Easy and precise cutting, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

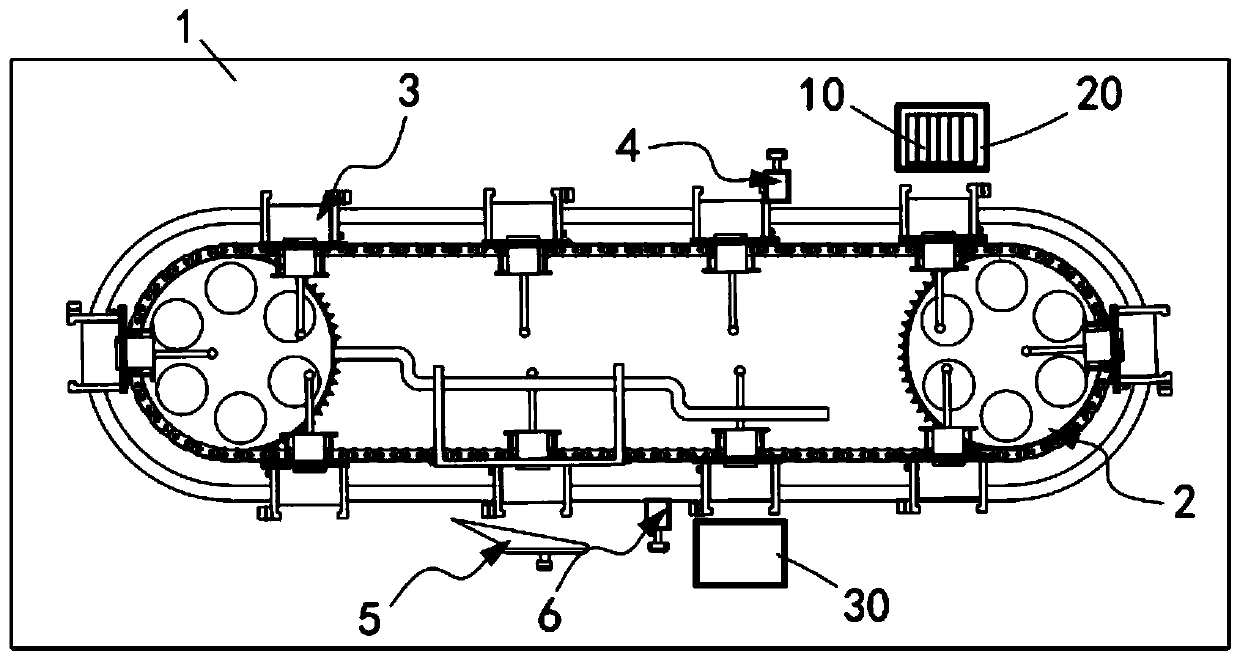

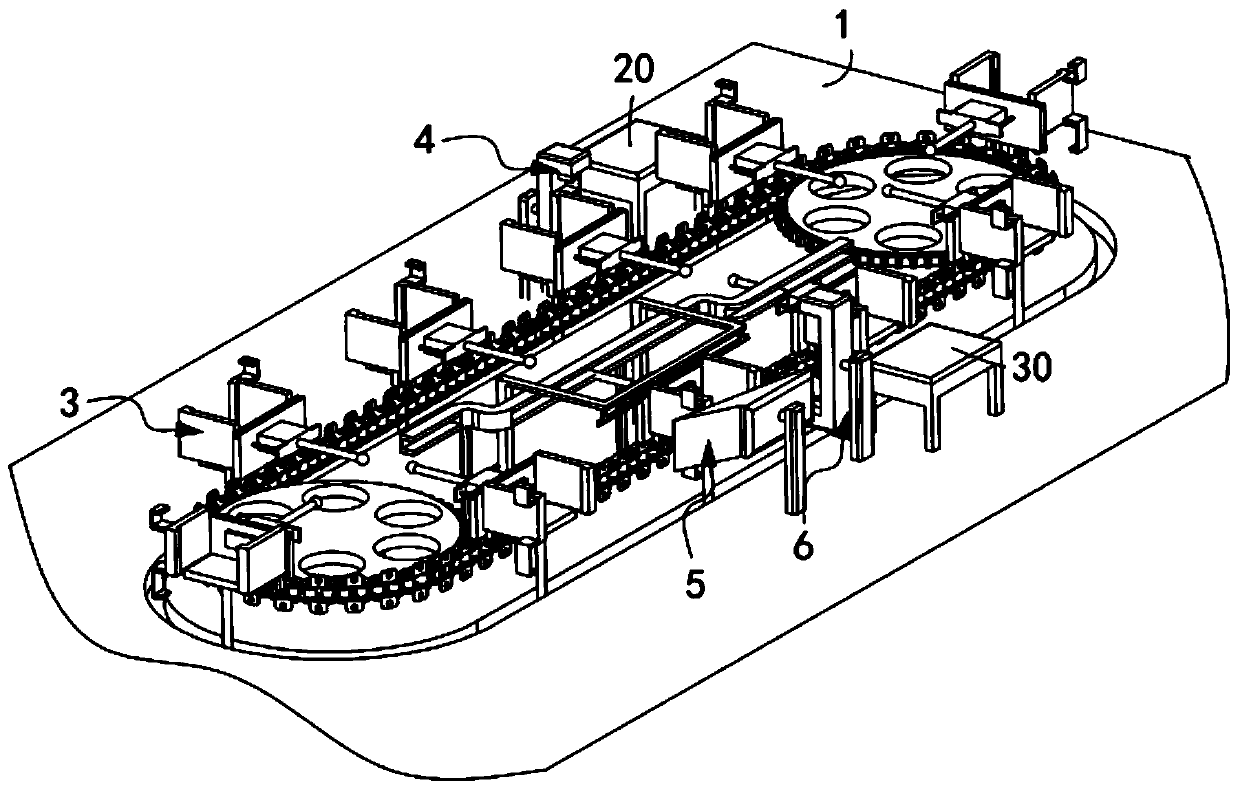

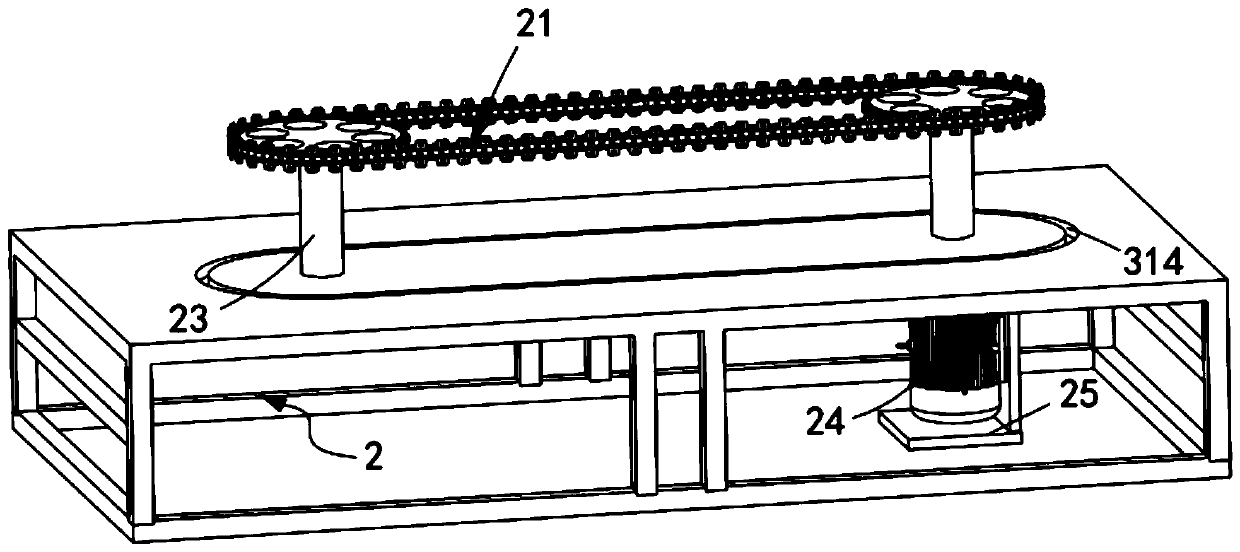

[0074] Such as figure 1 , figure 2 As shown in the figure, a battery plastic case burr processing equipment includes a frame 1, a turnover mechanism 2 installed on the frame 1, and several sets of clamping mechanisms 3 equidistantly arranged along the transmission direction of the turnover mechanism 2;

[0075] The frame 1 is provided with an upper loading station 4a, a cutting station 5a, and a discharging station 6a in sequence along the rotation direction of the turnover mechanism 2, and the upper loading station 4a is provided with an upper loading mechanism 4, and the cutter The position 5a is provided with a cutting mechanism 5, and the discharge station 6a is provided with a discharge mechanism 6;

[0076] The battery case 10 is uploaded from the loading station 4a to the clamping mechanism 3 through the loading mechanism 4, enters the cutting station 5a driven by the turnover mechanism 2, and completes the burr processing work through the cutting mechanism 5, and the...

Embodiment 2

[0122] Such as Figure 17 , Figure 18 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0123] further, such as Figure 17 , Figure 18 As shown, the horizontal pushing assembly 51 includes:

[0124] A pushing member 511, the pushing member 511 includes a push plate 5111, a support 5112 fixed to the outside of the push plate 5111 and two sets of telescopic units c5113 connecting the support 5112 and the outside of the side plate 315, and the side plate 315 is provided with a sliding groove 5114, the push plate 5111 is matched and slidably arranged in the sliding groove 5114; and

[0125] The guide rail 512, the guide rail 512 includes a first horizontal part 5121, a second horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com