Chlorine dioxide reaction device

A reaction device and chlorine dioxide technology, applied in chlorine oxide and other directions, can solve the problems of complex composition and unattainable system working efficiency, and achieve the effects of promoting release, preventing excessive gas pressure and increasing production output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

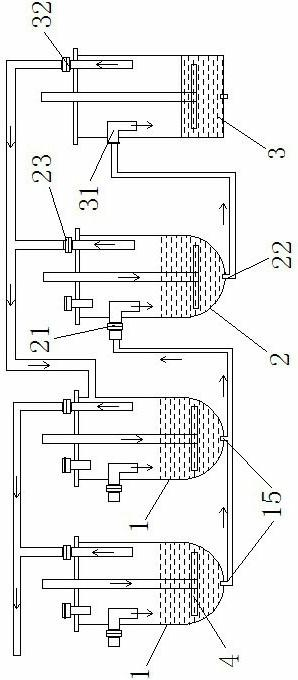

[0022] Such as figure 1 As shown, a chlorine dioxide reaction device includes two main reactors 1 and a secondary reactor 2, and is characterized in that: two primary reactors 1 are connected in parallel to form a first-stage reaction, and the secondary reactor 2 is connected in parallel with two The main reactor 1 is connected in series to form the second-stage reaction, and the secondary reactor 2 and the gas-liquid blower 3 are connected in series to form the third-stage reaction; after the outlet pipe 21 of the secondary reactor 2 and the outlet pipe 32 of the gas-liquid blower 3 are connected It is connected to one of the main reactors 1, and the parallel outlet pipes of the two main reactors 1 are connected to the collection tank. The inlet pipes 11 of the two main reactors 1 are connected to each other and then connected to the raw material tank; the drain pipes 15 of the two main reactors are connected to each other and connected to the inlet pipe 21 in the secondary ...

Embodiment 2

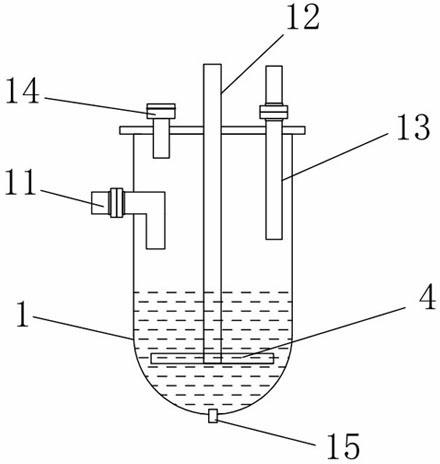

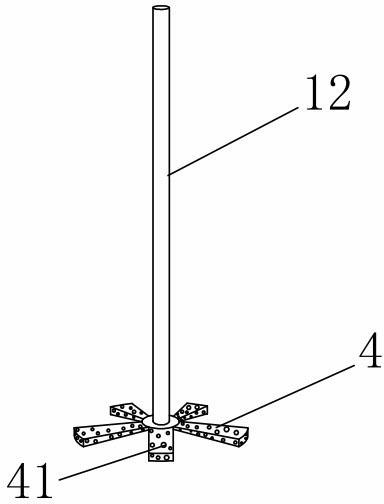

[0025] Such as figure 2 and image 3 As shown, the specific implementation is the same as in Example 1, and the difference is that the structure of the main reactor 1 is that the side wall is provided with a liquid inlet pipe 11, and the top of the kettle is provided with an air inlet pipe 12, an air outlet pipe 13 and an explosion-proof device 14; The trachea 12 extends to the lower part of the reactor and is submerged by the solution. The bottom of the inlet pipe 12 is provided with stirring blades 4 , and each stirring blade 4 is provided with an air outlet 41 ; the bottom of the reactor is provided with a drain pipe 15 .

[0026] The raw material enters the main reactor 1 through the liquid inlet pipe 11 of the main reactor 1 for the first-stage reaction, and the two main reactors 1 are connected in parallel with each other. 13 are connected in parallel with each other, and the supply and discharge are carried out uniformly but independent of each other without affecting...

Embodiment 3

[0028] The specific embodiment is the same as Example 2, the difference is that: the inlet pipe 12 of the main reactor 1 is located in the middle of the top of the kettle; the stirring blade 4 is cylindrical, and the stirring blade 4 rotates around the inlet pipe 12; the air outlet 41 is along the evenly distributed around the circumference.

[0029] Stirring blade 4 itself also rotates, cooperates air outlet 41 to cause the double agitation solution of solution, promotes the carrying out of reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com