Method and device for fixing a sheet of glass with counter-blade

A watch glass and fastening technology, which is applied in the field of watch manufacturing, can solve the problems of a large amount of investment, etc., and achieve the effect of facilitating assembly and improving sturdiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

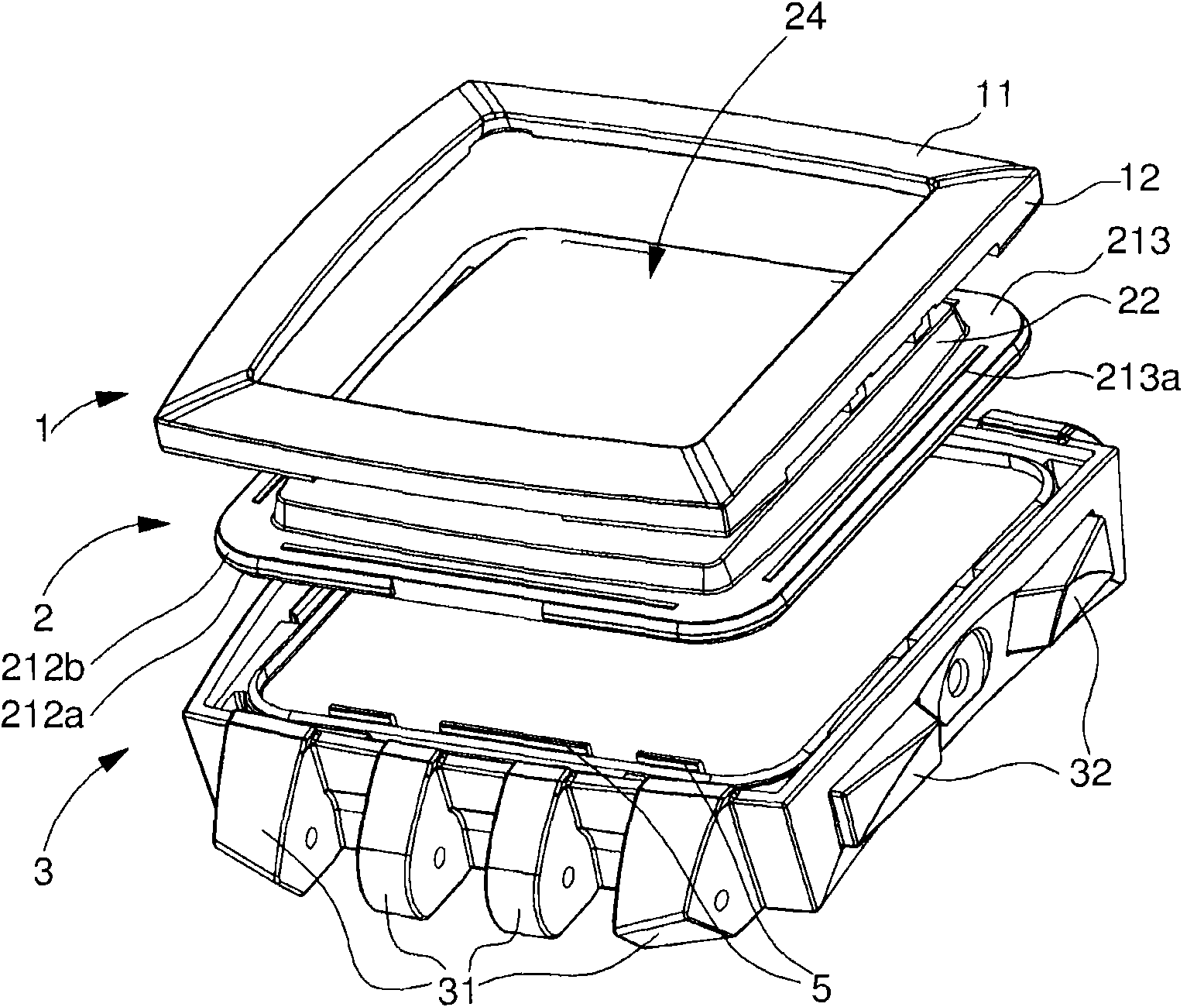

[0017] The present invention uses the concept of a snap fit or press fit installation, which involves elastic deformation of the elements during assembly, but unlike the push-in method (also specifically called setting in the jewelry field), which does not require friction to hold assembly position. The snap-fit assembly also differs from the push-in method in that since the snap-fit element then returns to the normal shape it had at rest before the snap-fit operation, once the snap-fit has started, the force applied to the snap-fit The deformation force on the component should disappear.

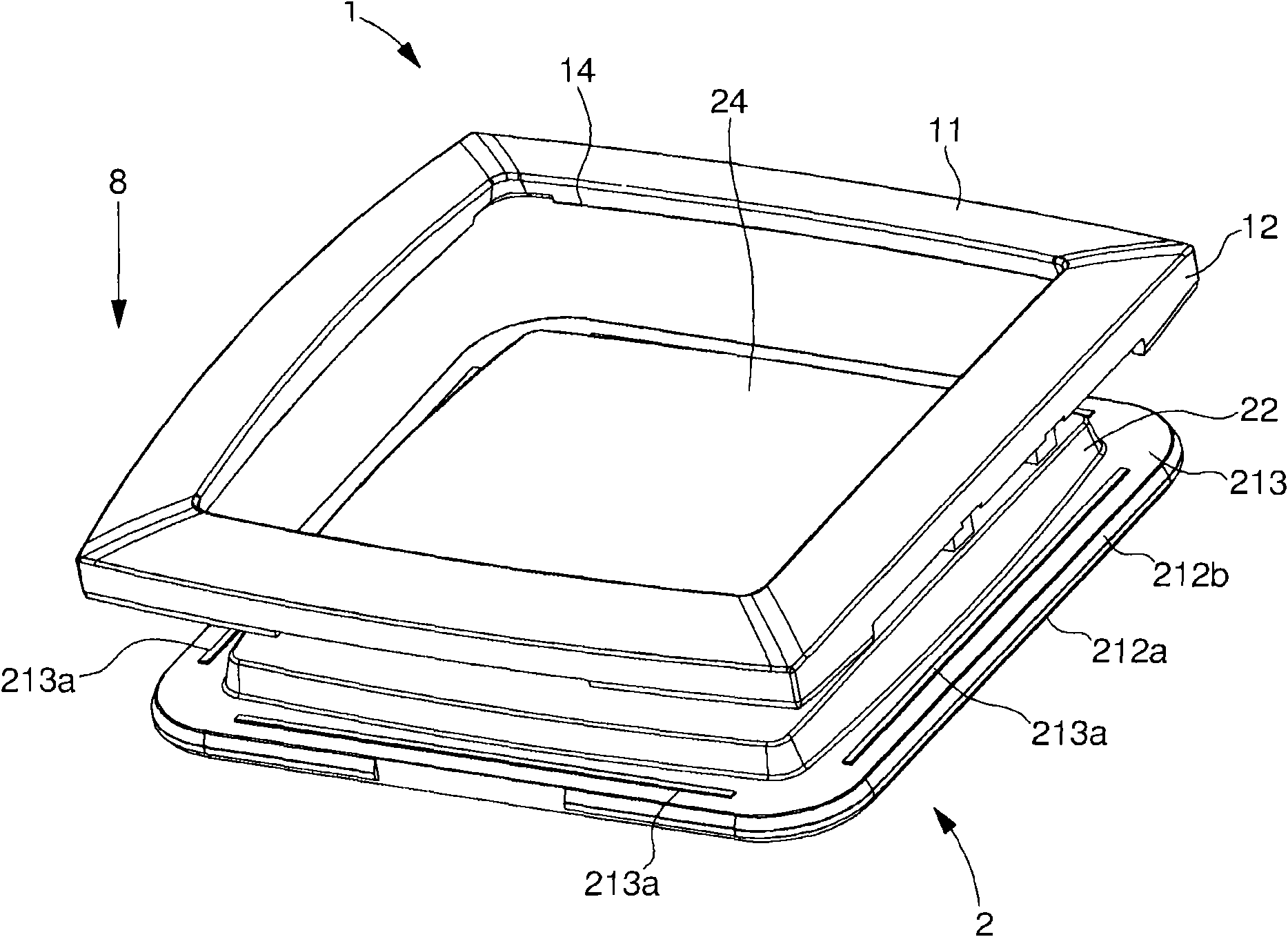

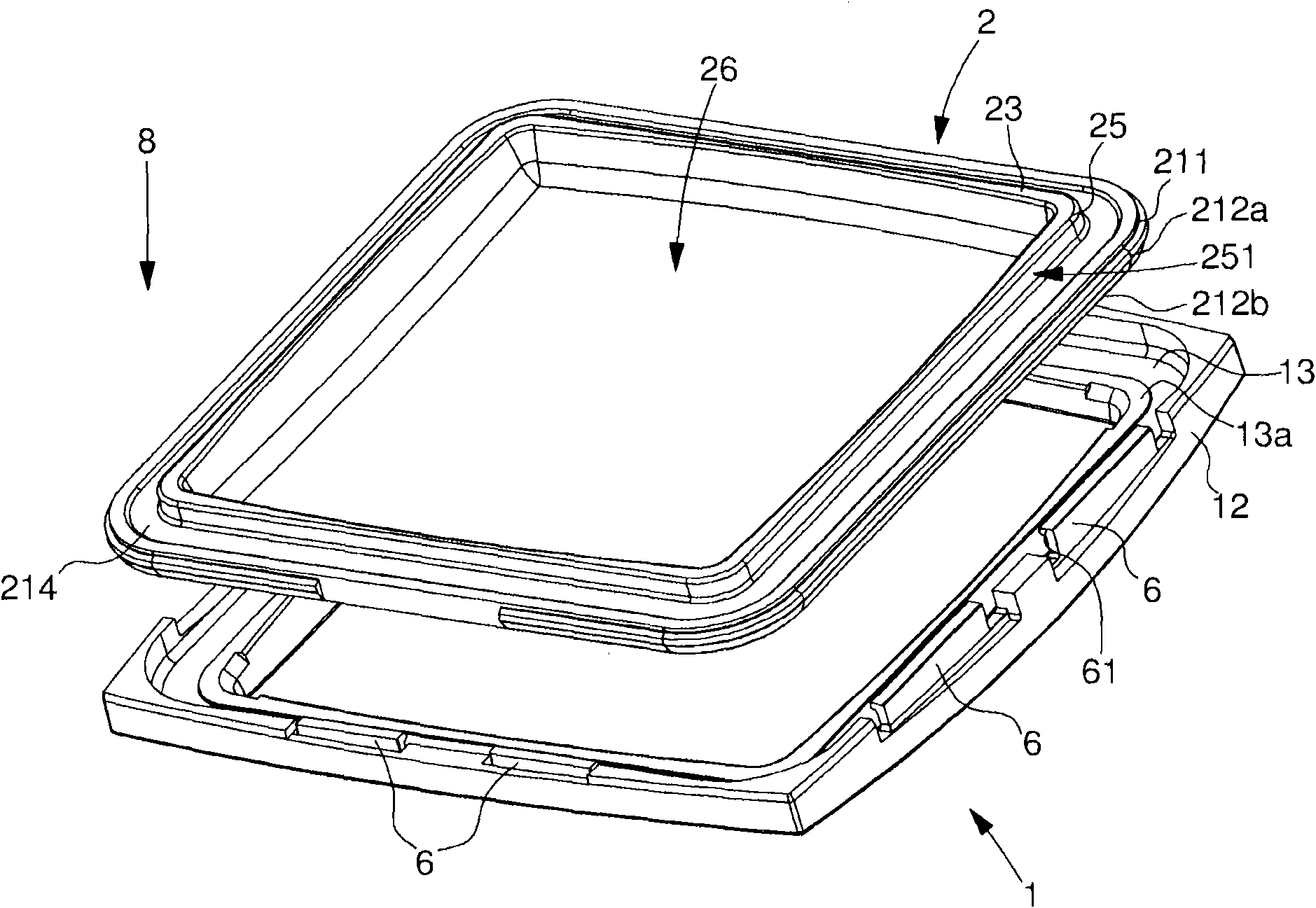

[0018] figure 1 Shows bezel 1 and crystal 2 not yet assembled to each other according to a preferred variant of the invention viewed from above, which concerns square plastic bezel 1 and crystal 2 .

[0019] On the bezel 1 is shown the outer substantially vertical wall 12 and the top outer surface 11 forming a substantially horizontal, slightly domed surface to better match the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com