Automatic bottom rotating device and process for heat preservation container product

A technology for thermal insulation containers and products, applied in measuring devices, testing of machines/structural components, instruments, etc., can solve problems such as easy brushing of the bottom, inconvenient positioning, etc., to reduce production costs, increase production output, and save operators Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

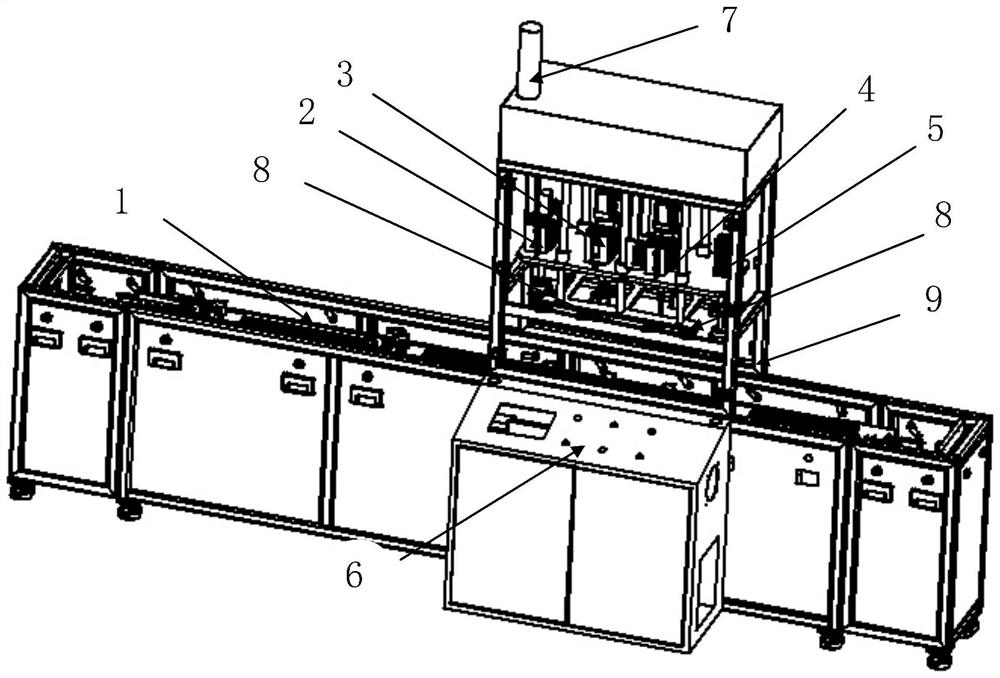

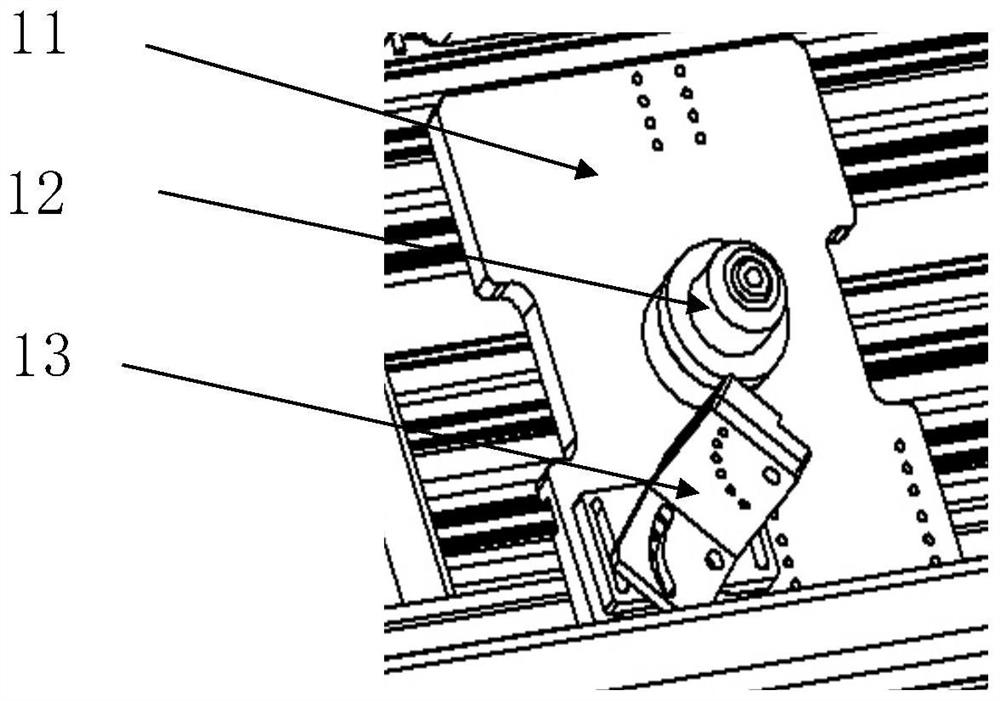

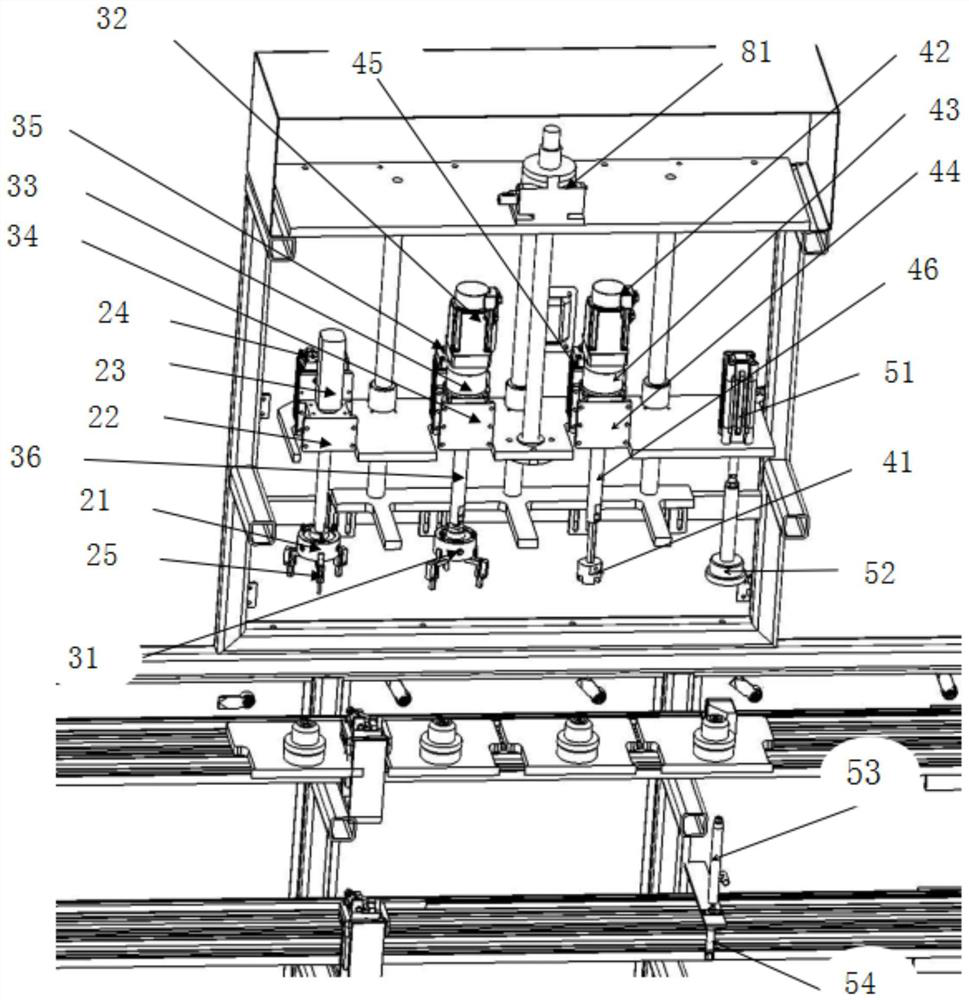

[0025] see Figure 1 ~ Figure 3, This embodiment consists of double-speed chain assembly line 1, pre-rotation positioning mechanism 2, large bottom tightening mechanism 3, bottom screw tightening mechanism 4, airtightness detection mechanism 5 and electrical control system. There are several running carriers 11 in the double-speed chain assembly line 1. The center position of the running carrier 11 is provided with a positioning head 12. The positioning head 12 is positioned centrally with the bottle mouth of the heat preservation container. There is an inclined plane with an included angle of 90 degrees at the bottom of the through hole, and the outside of the positioning head 12 is provided with anti-scratch soft silica gel. The edge of the running carrier 11 is provided with an adjustable stall stop block 13 to ensure that the stall stop block can play t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com