Patents

Literature

44results about How to "High degree of work automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

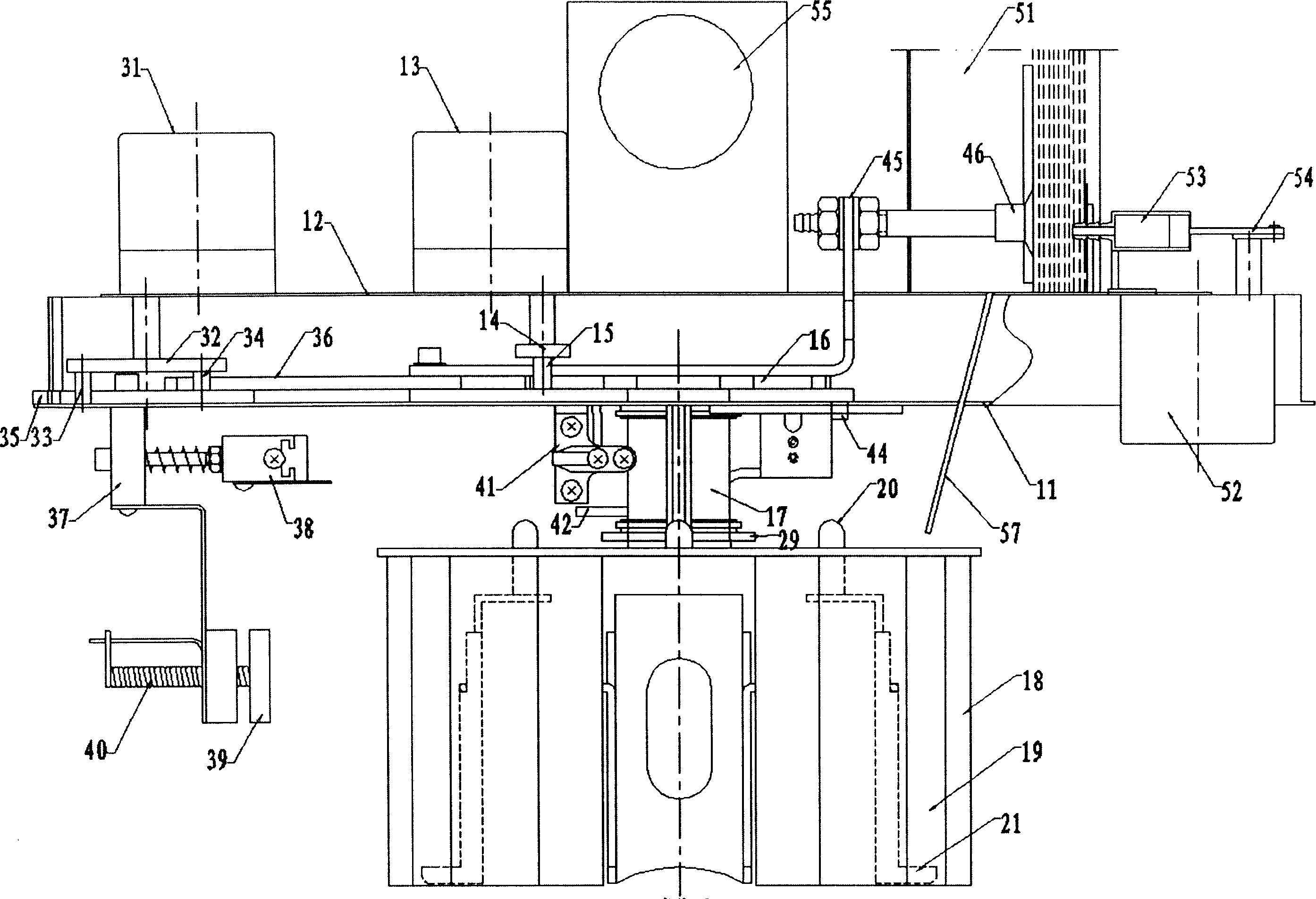

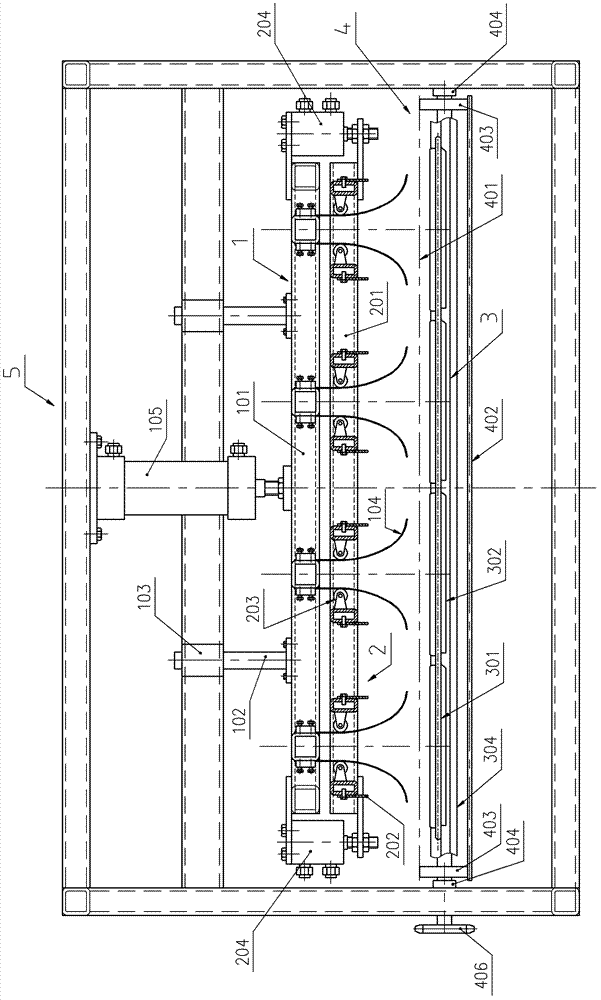

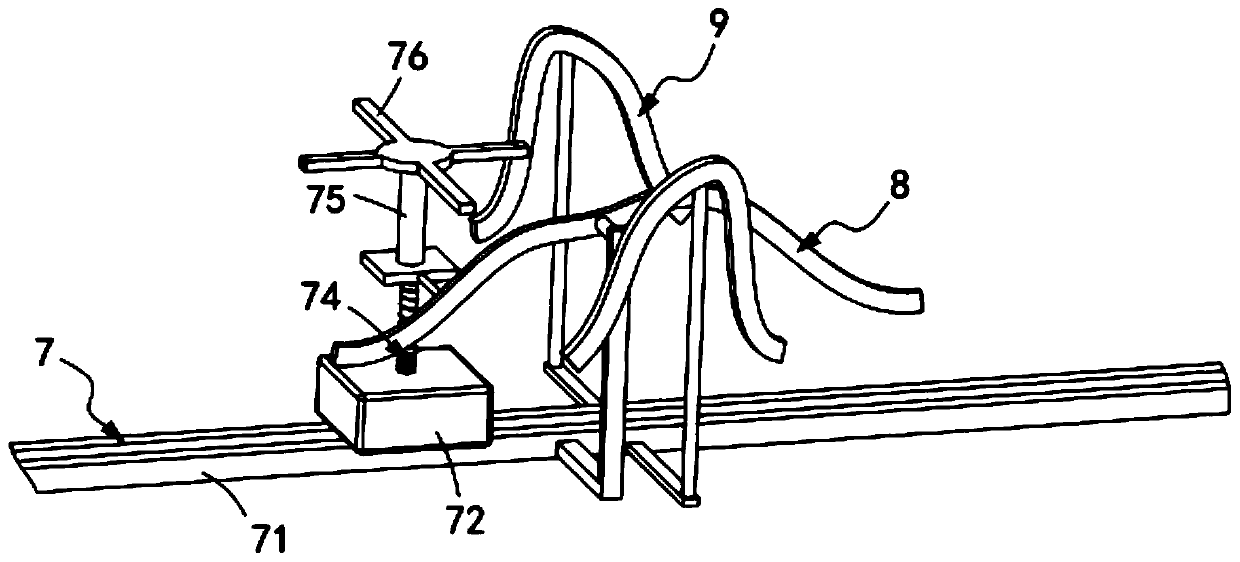

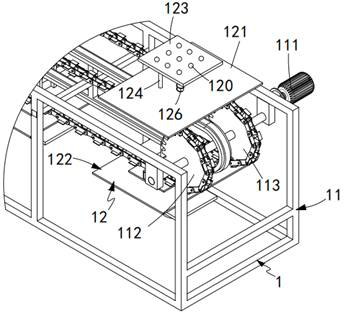

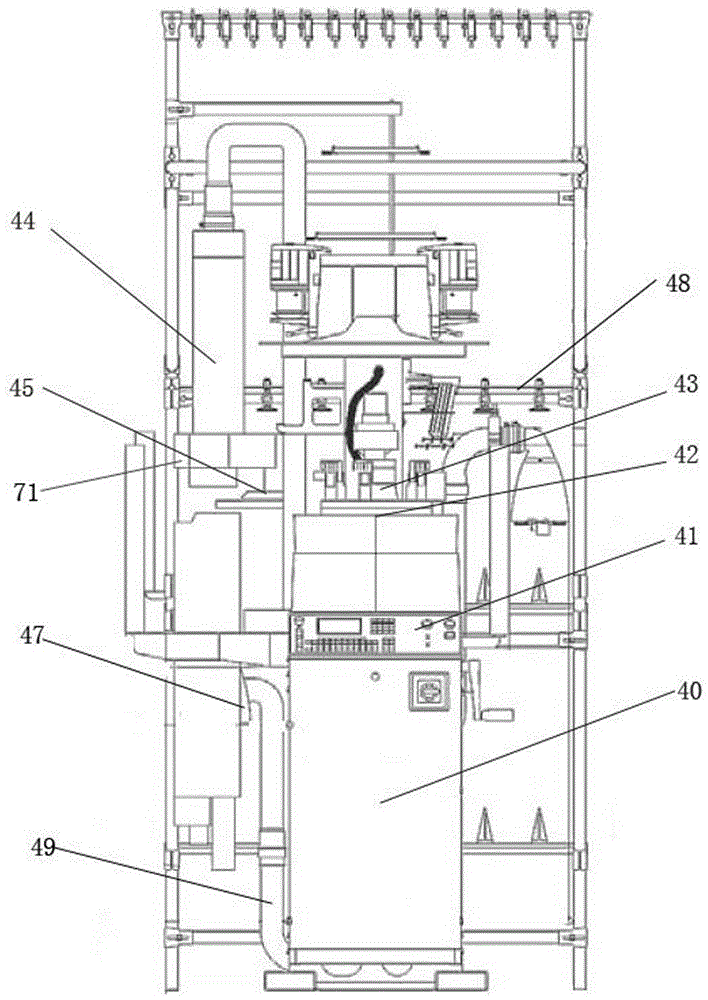

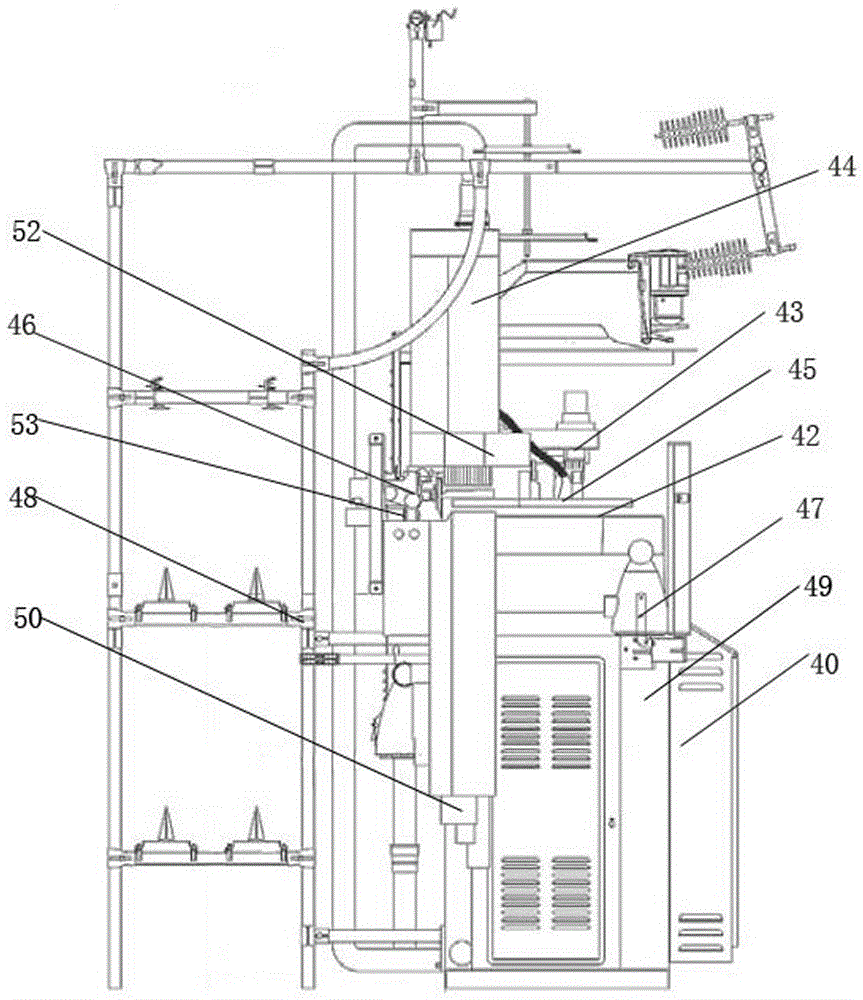

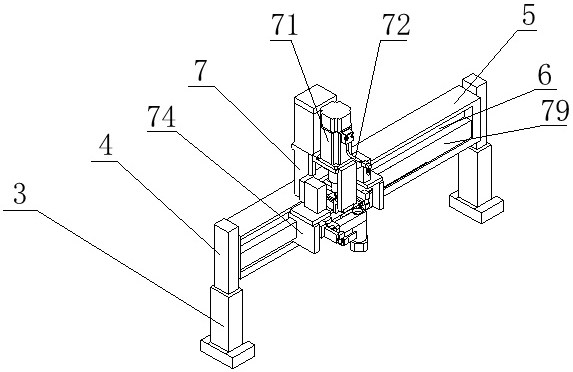

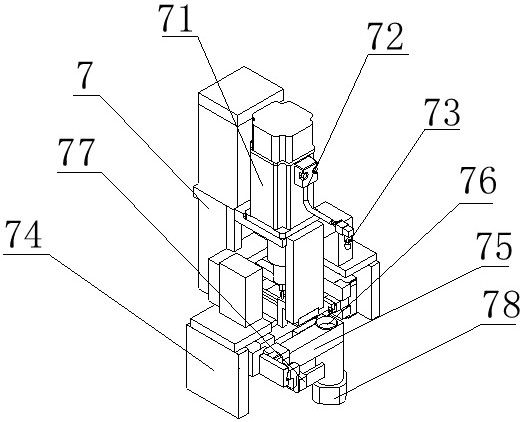

Hosiery knitting and end sewing integrated weft knitting hosiery knitter and use method

ActiveCN104611823AHigh degree of work automationMechanical cleaningPressure cleaningElectric machineryEngineering

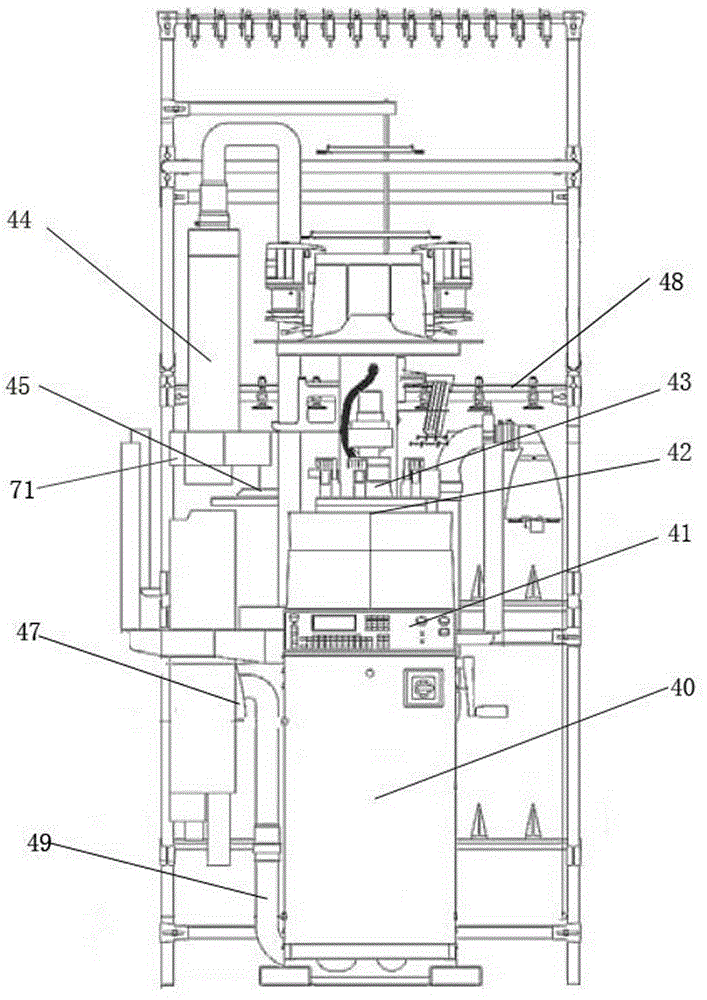

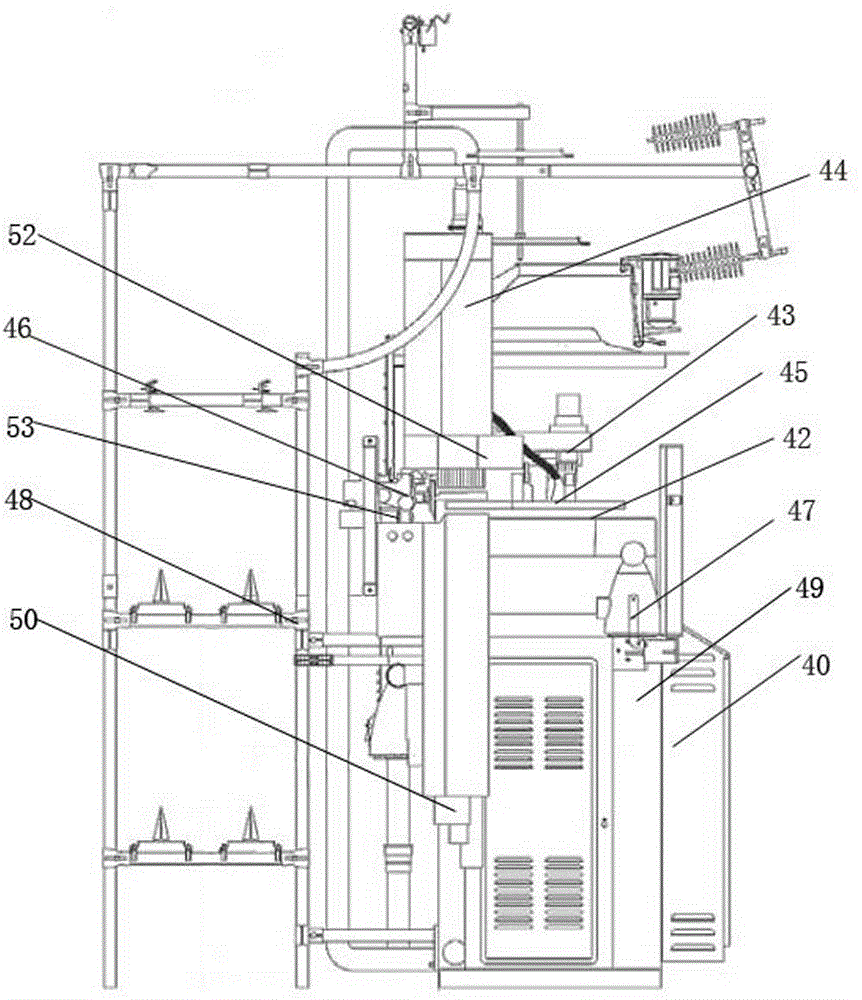

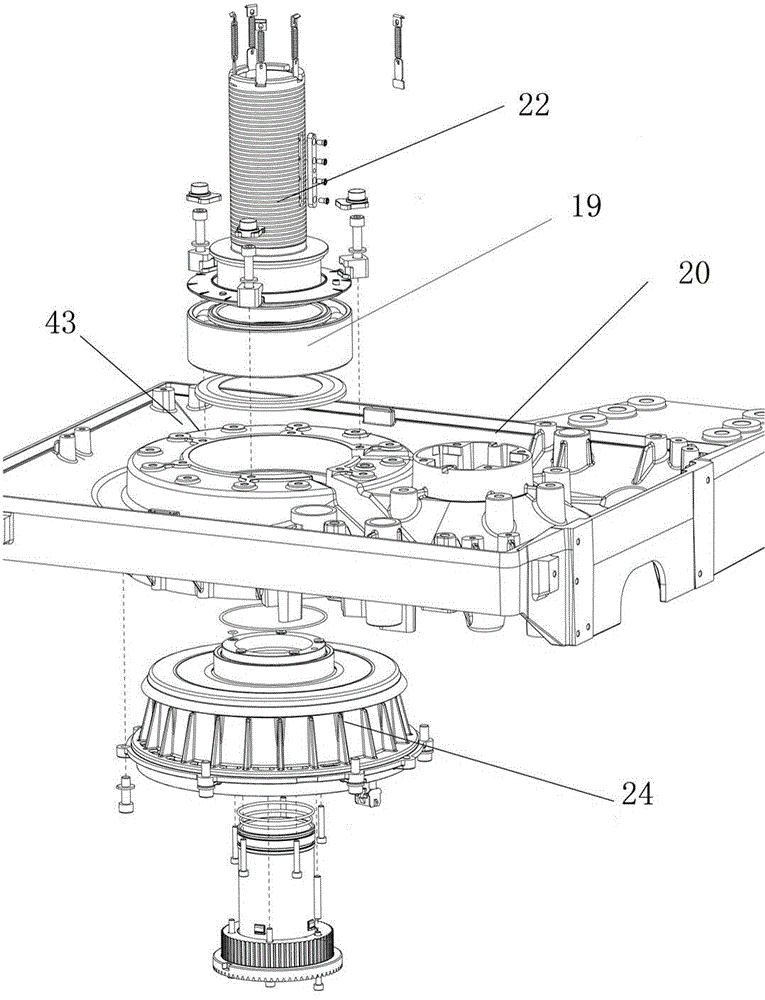

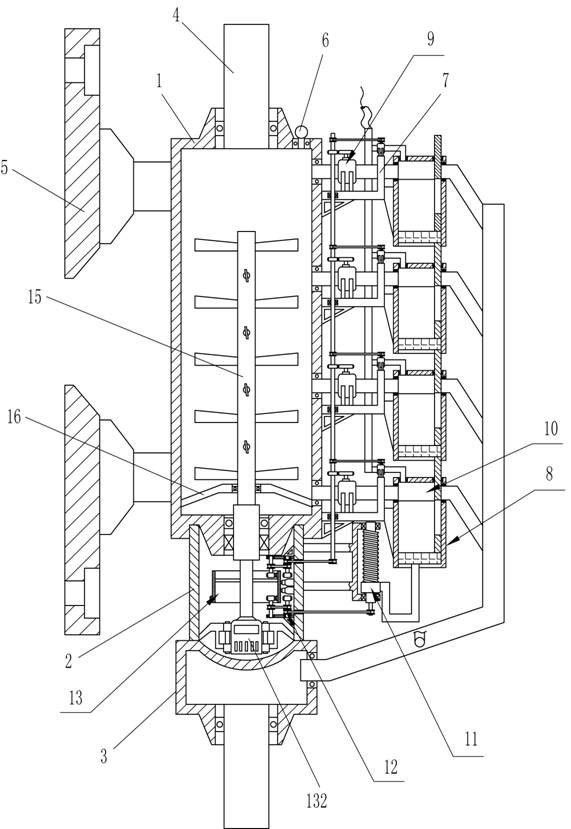

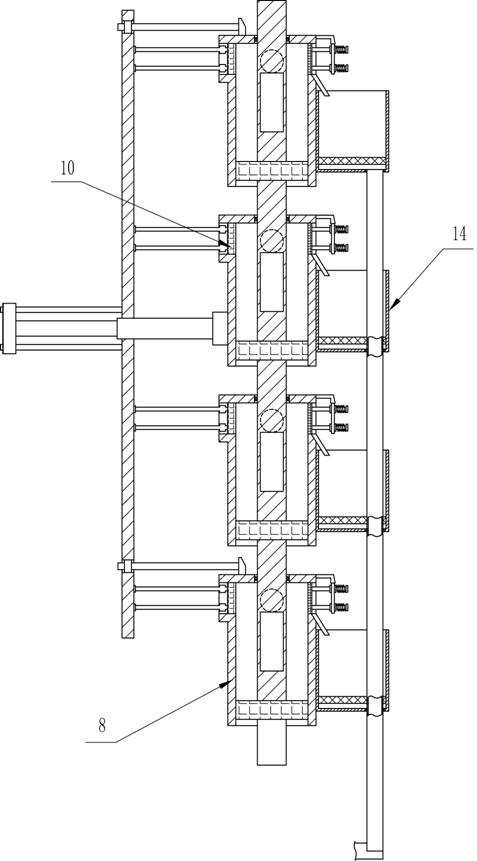

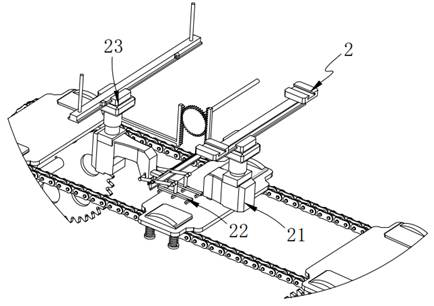

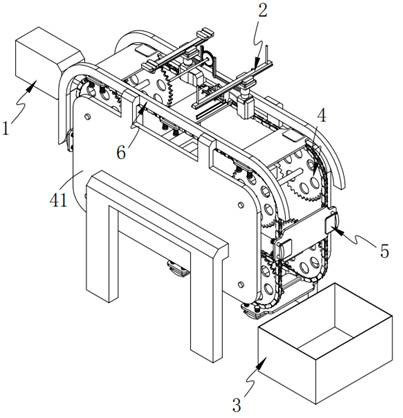

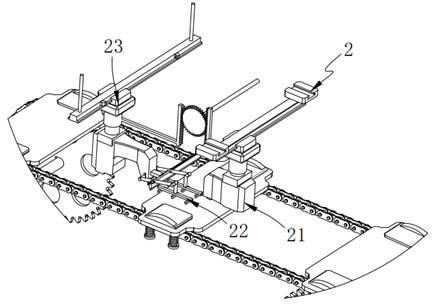

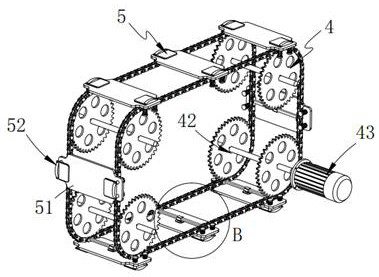

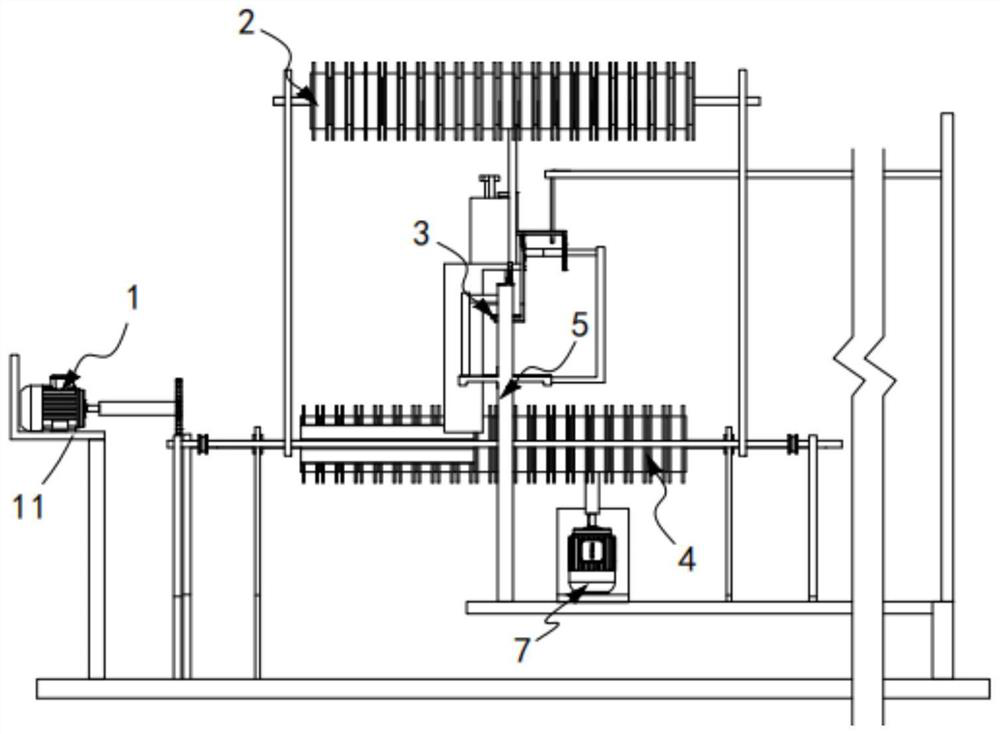

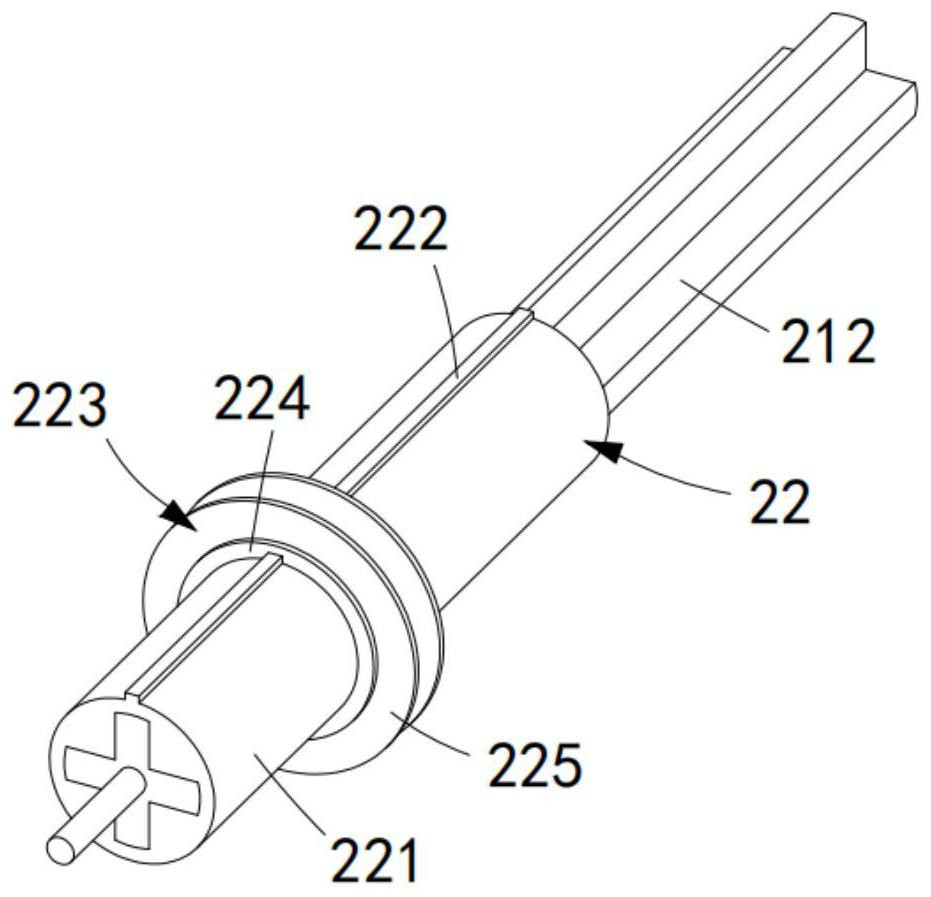

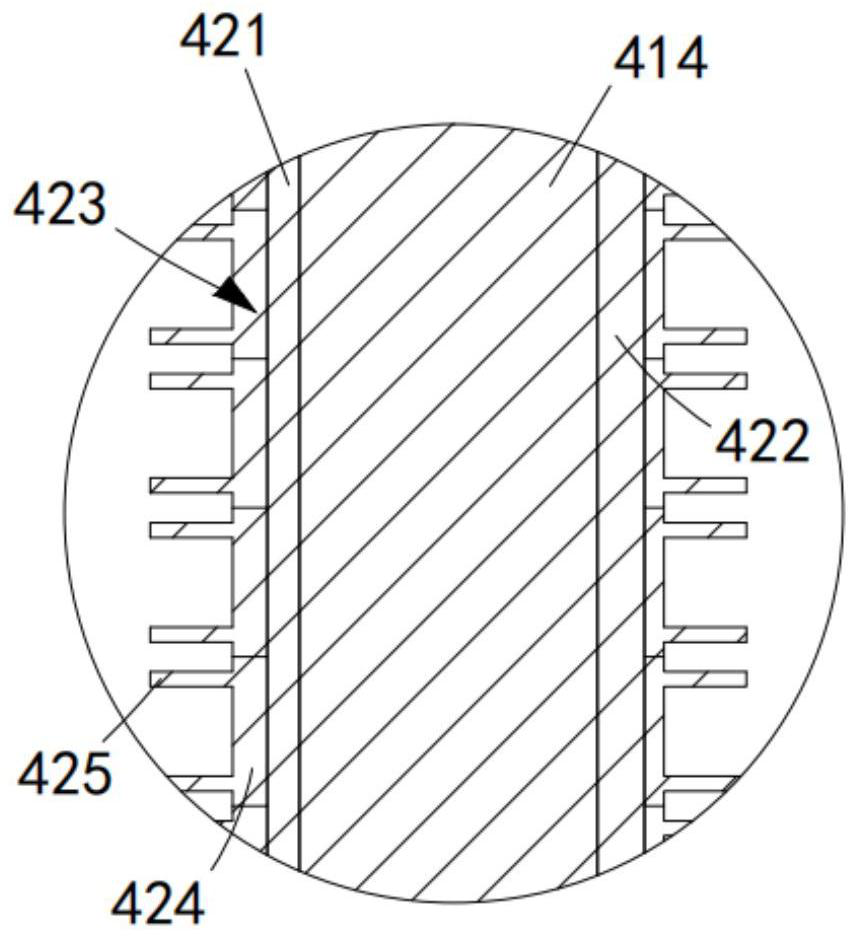

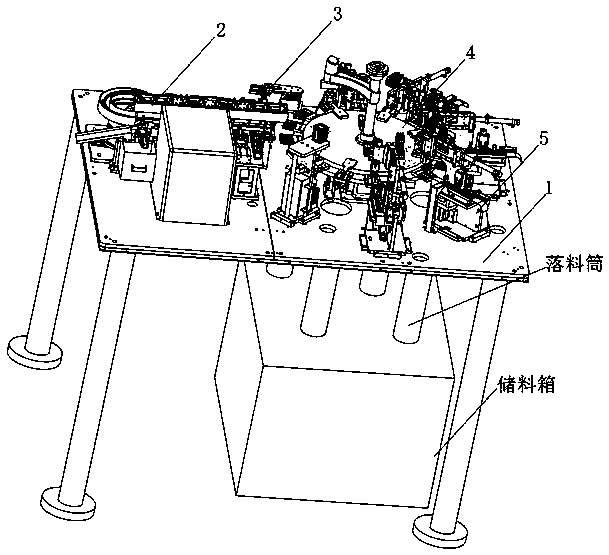

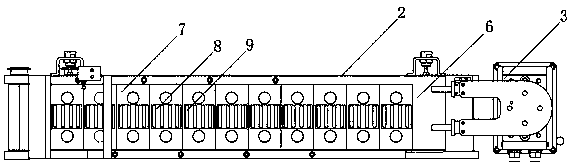

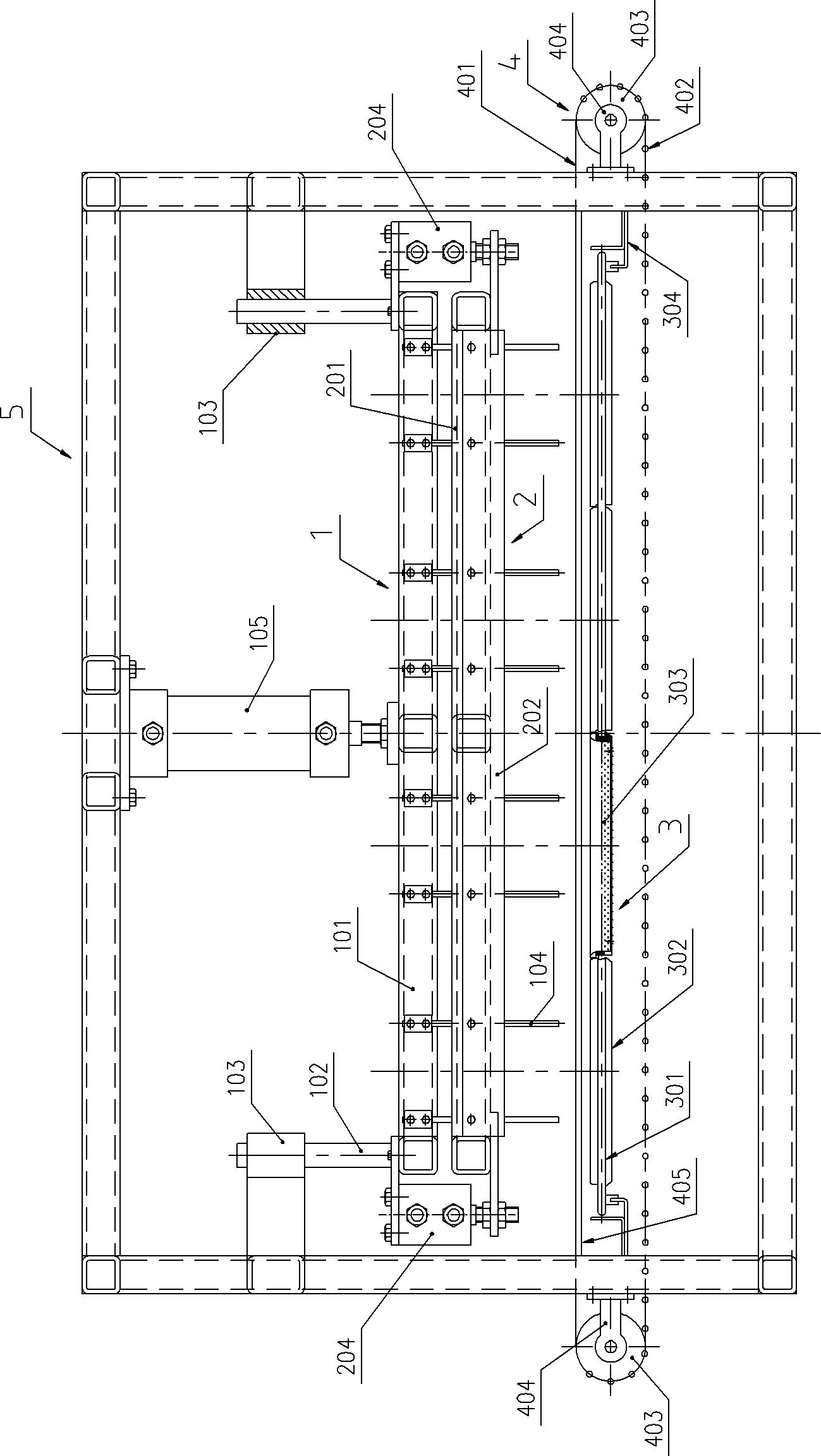

The invention discloses a hosiery knitting and end sewing integrated weft knitting hosiery knitter. A control panel is arranged on an electric control box. A working table is installed on a working box and provided with a hosiery knitting machine, a hosiery turning device, a mechanical arm and an end sewing machine. The mechanical arm is located between the hosiery knitting machine and the hosiery turning device. The hosiery turning device and the end sewing machine are located on the same straight line. The hosiery knitting machine is connected with a main motor through a conveying belt. The hosiery turning device is connected with a hosiery turning rod lifting motor and a tongs lifting motor through transmission devices respectively. A pair of mechanical arm tongs is installed on the mechanical arm. The mechanical arm is connected with a rotating motor through a worm and a gear. The end sewing machine is connected with an end sewing motor through a driving belt. The control panel is connected with the main motor, the hosiery turning rod lifting motor, the rotating motor and the end sewing motor through circuits respectively. An air suction pipe is arranged on the hosiery turning device and provided with a hosiery outlet cover. Thus, the hosiery knitting work, the hosiery turning work and the end sewing work can all be completed at a high automation degree.

Owner:诸暨镭尔福机械科技有限公司

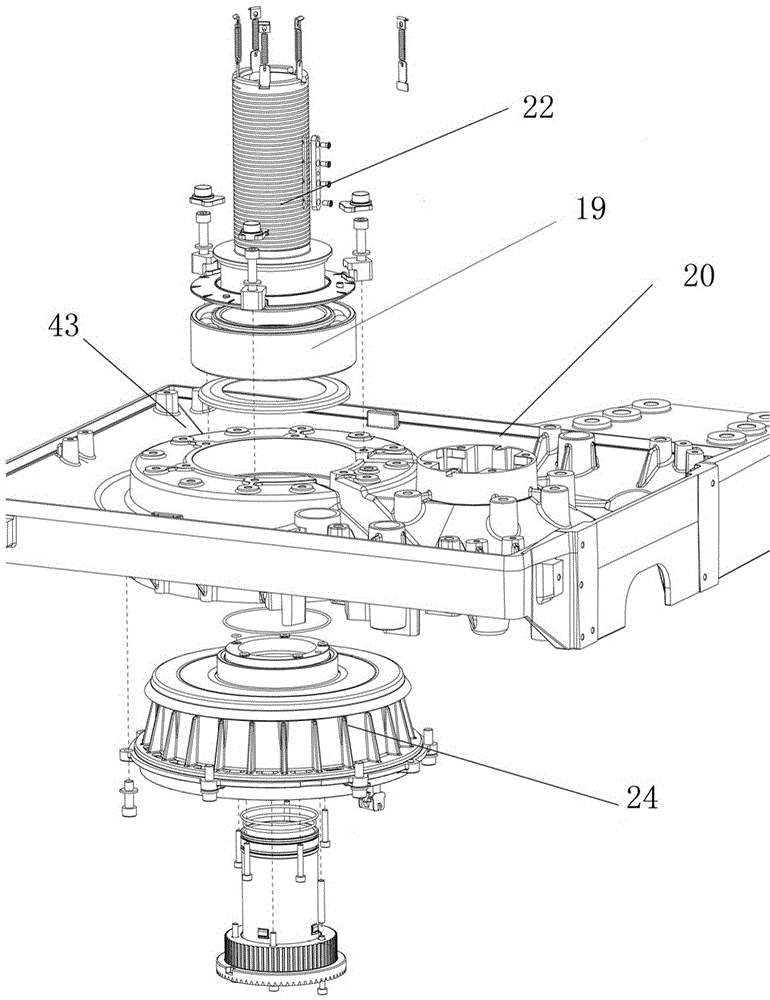

Minitype vertical liquid packing machine

InactiveCN1907810ALess flow pathNot prone to pollutionWrapper twisting/gatheringPackaging automatic controlPulp and paper industrySlide plate

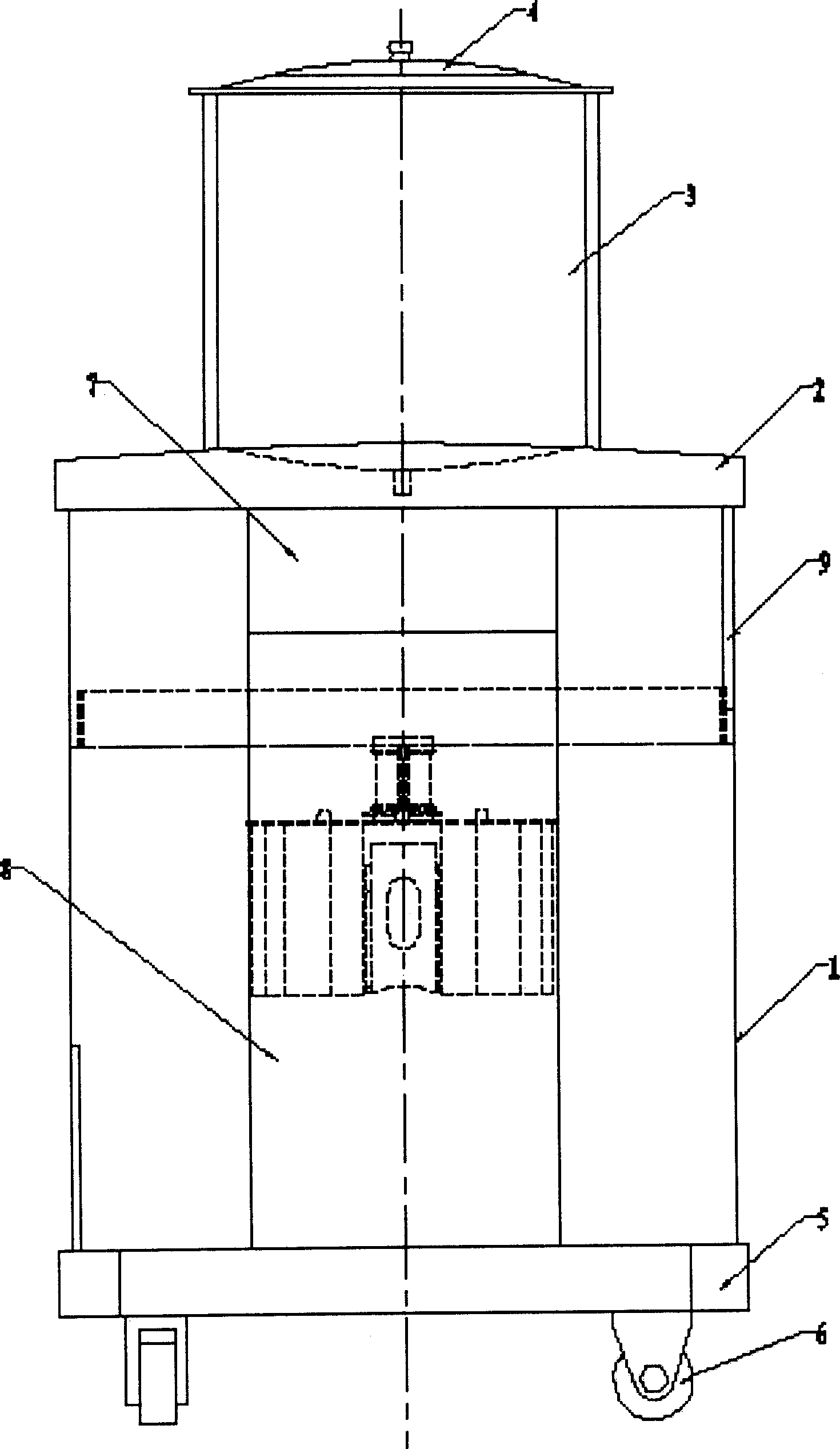

The invention relates to a small upright liquid packing machine, which is formed by cylinder frame, liquid pot, and packing integration, wherein the packing integration comprises rotator, main controller, bag feeder, filler, and sealing device; the rotator is formed by rotational motor, dial fork disc, mume wheel, and the rotational wheel with several bag grooves; the main controller is formed by main control motor, main control dial fork disc, upper sliding plate, and lower sliding plate; the bag feeder is formed by bag chamber, adsorption disc, adsorption motor, and plug pump; the filler is formed by blower, micro switch, filling motor and filing ejector; the sealing device is formed by sealing block, sealing compressor and sealing heater. The invention can pack liquid in small patch, with high automatic degree, stable operation, better sealing property, and wider application, without liquid pollution.

Owner:南浩俊

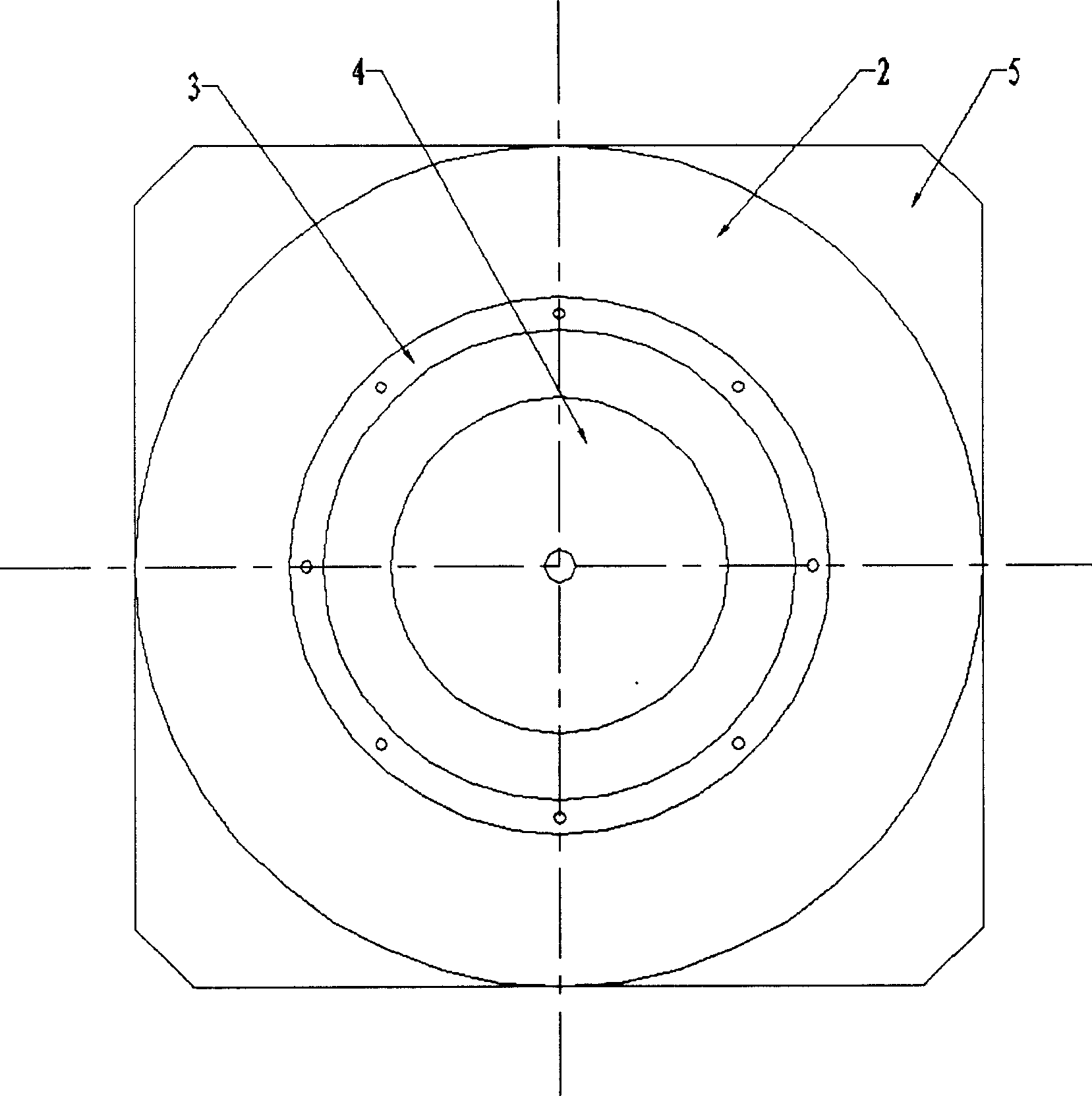

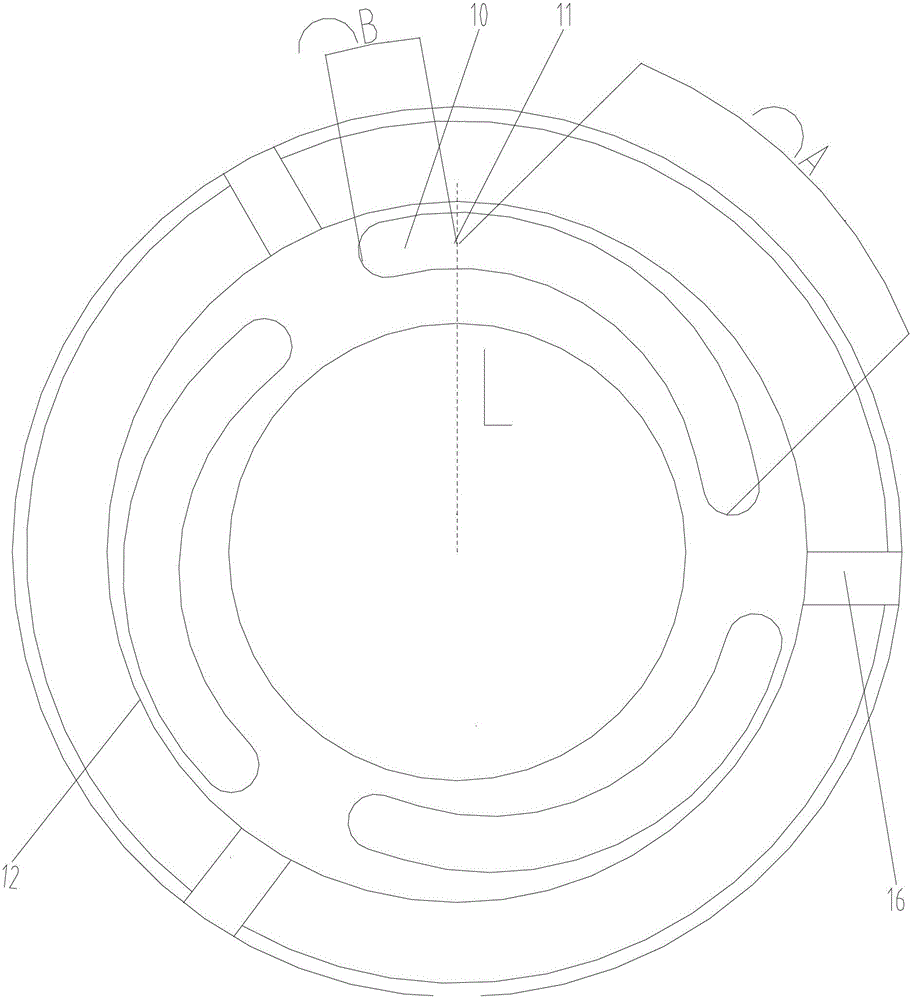

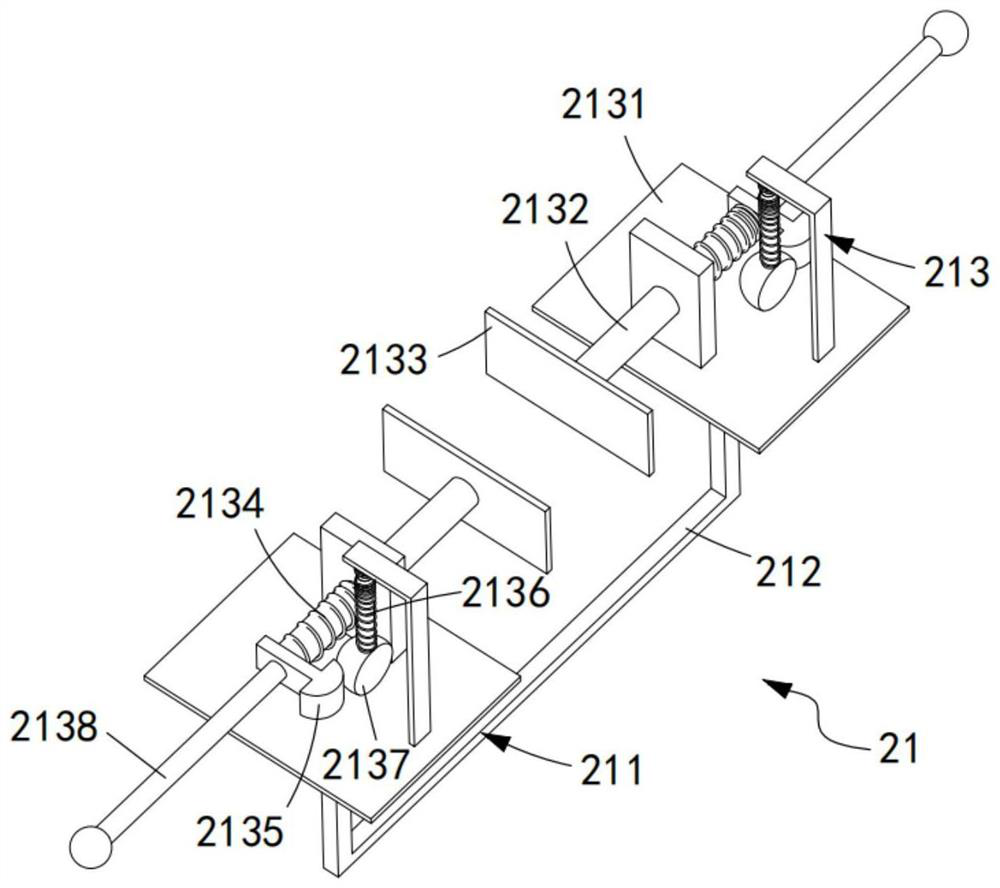

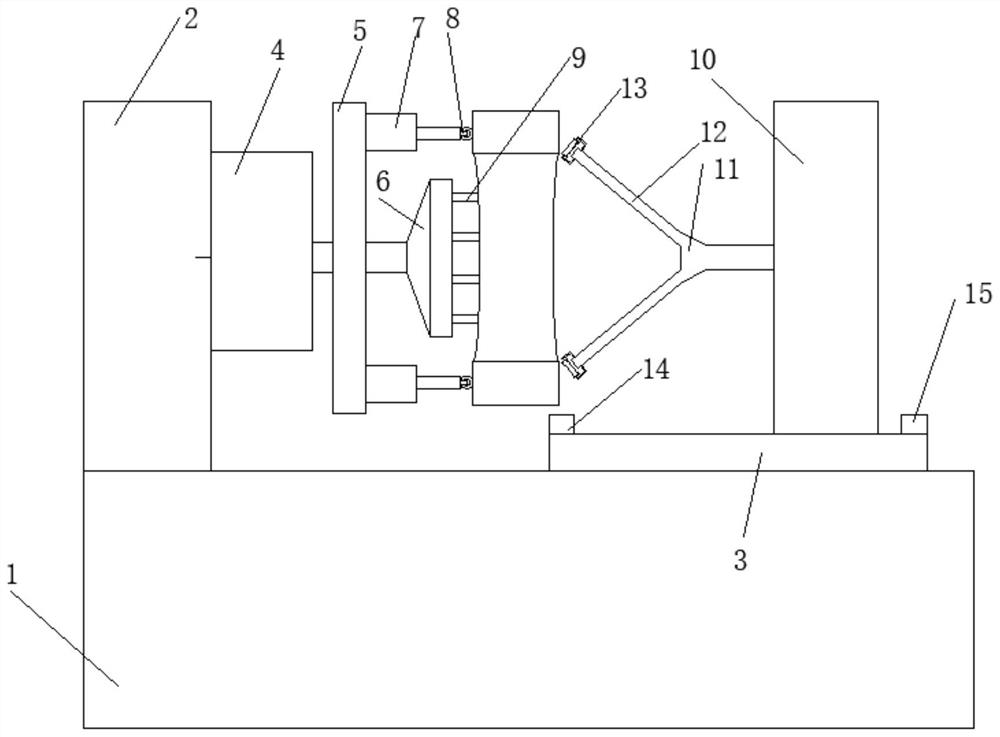

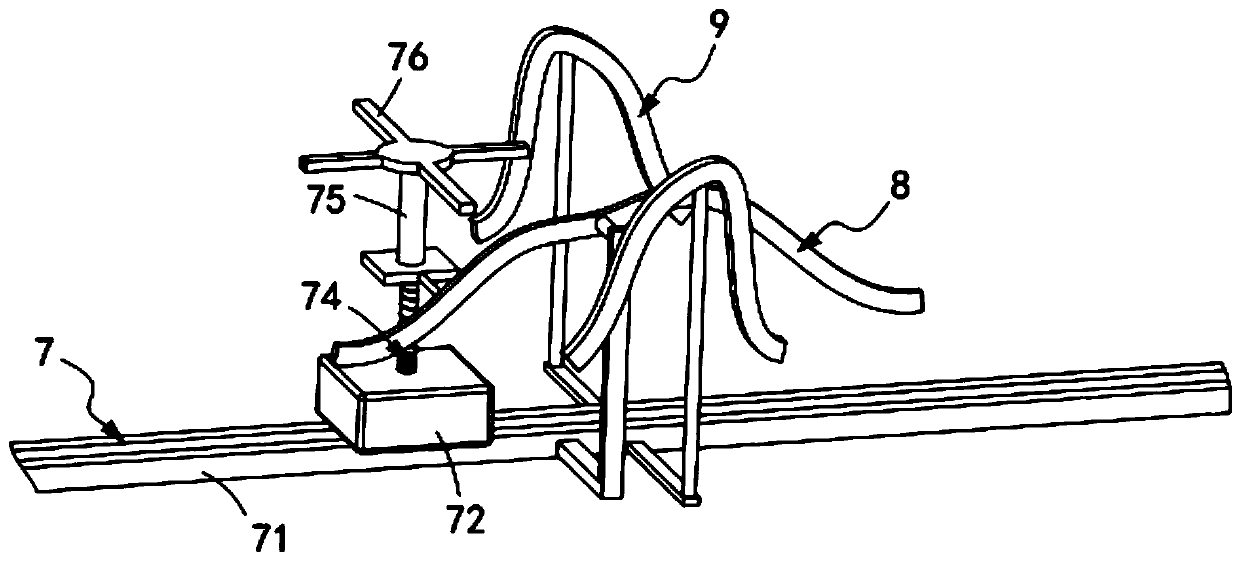

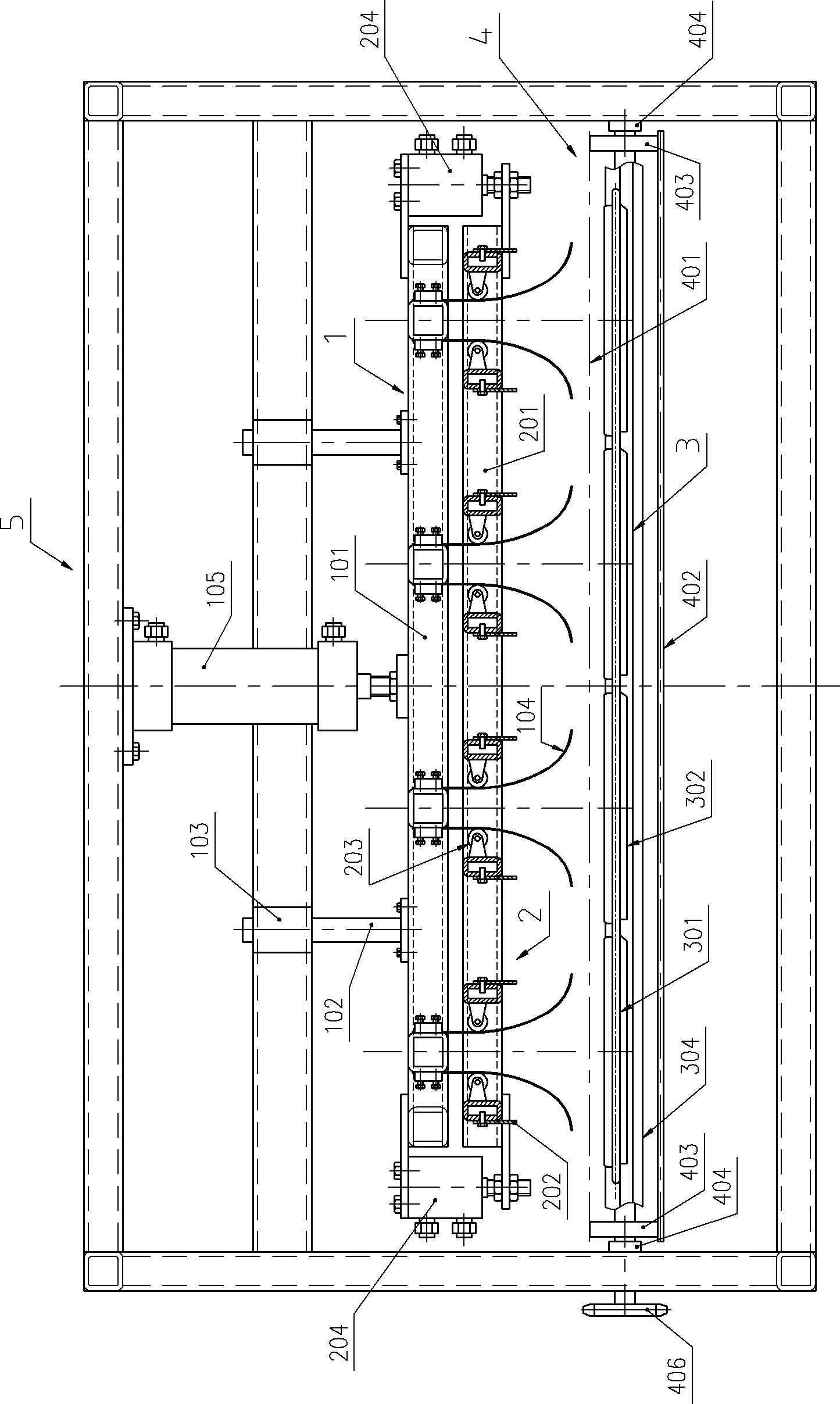

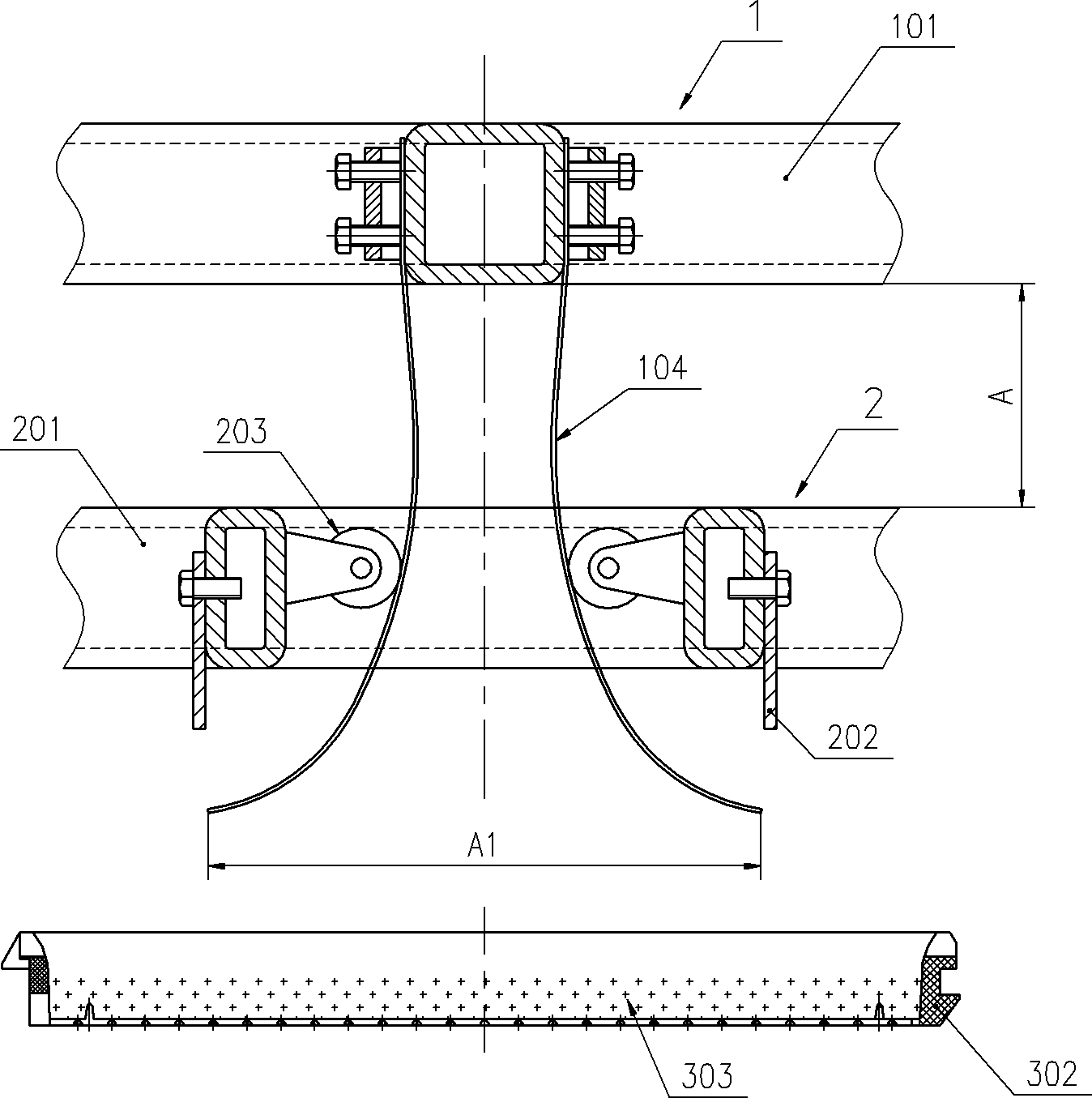

Connector for connecting loading arm with tank truck

InactiveCN103148297AExtended service lifeHigh degree of work automationCouplingsTank truckEngineering

The invention discloses a connector for connecting a loading arm with a tank truck. The connector comprises a base, at least three shaft lugs uniformly distributed and fixed along the outer edge of the base, and a rotary plate rotationally connected with the base, wherein each shaft lug is hinged with a clamping jaw used for connecting the base with the connector end of the tank truck; arc-shaped grooves corresponding to the clamping jaws in number are formed in the rotary plate; the center of each arc-shaped groove deviates from that of the rotary plate; and the lower end of each clamping jaw is positioned in the corresponding arc-shaped groove. According to the connector provided with the rotary plate, the clamping jaws can rotate relative to the shaft lugs by rotating the rotary plate only, and the loading arm is stably connected with the tank truck, so that the automation level in the working process is high, the working process is safe and reliable, and the service life of each clamping jaw is prolonged.

Owner:JIANGSU CHANGLONG PETROCHEM EQUIP

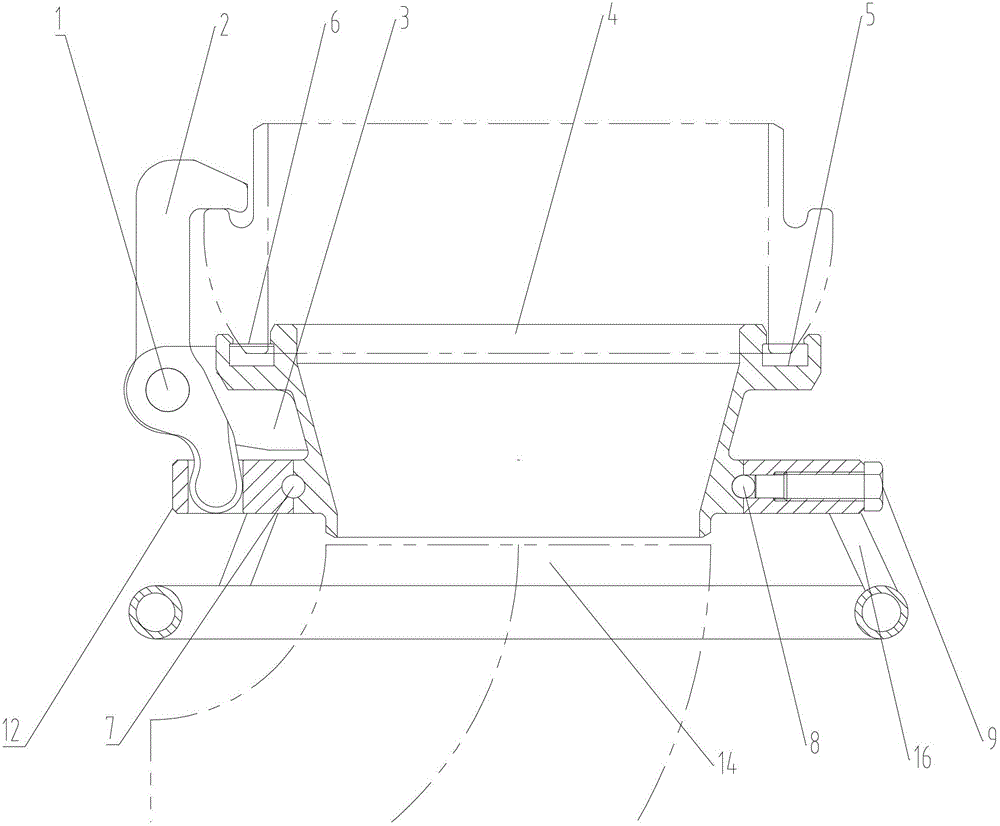

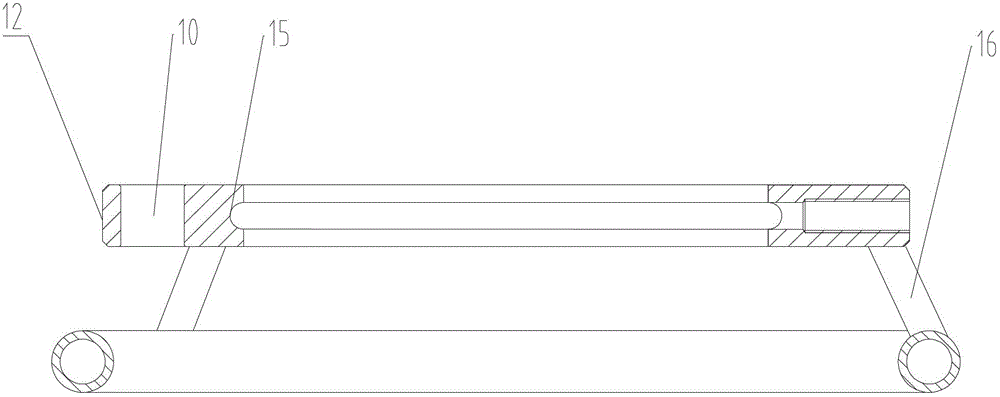

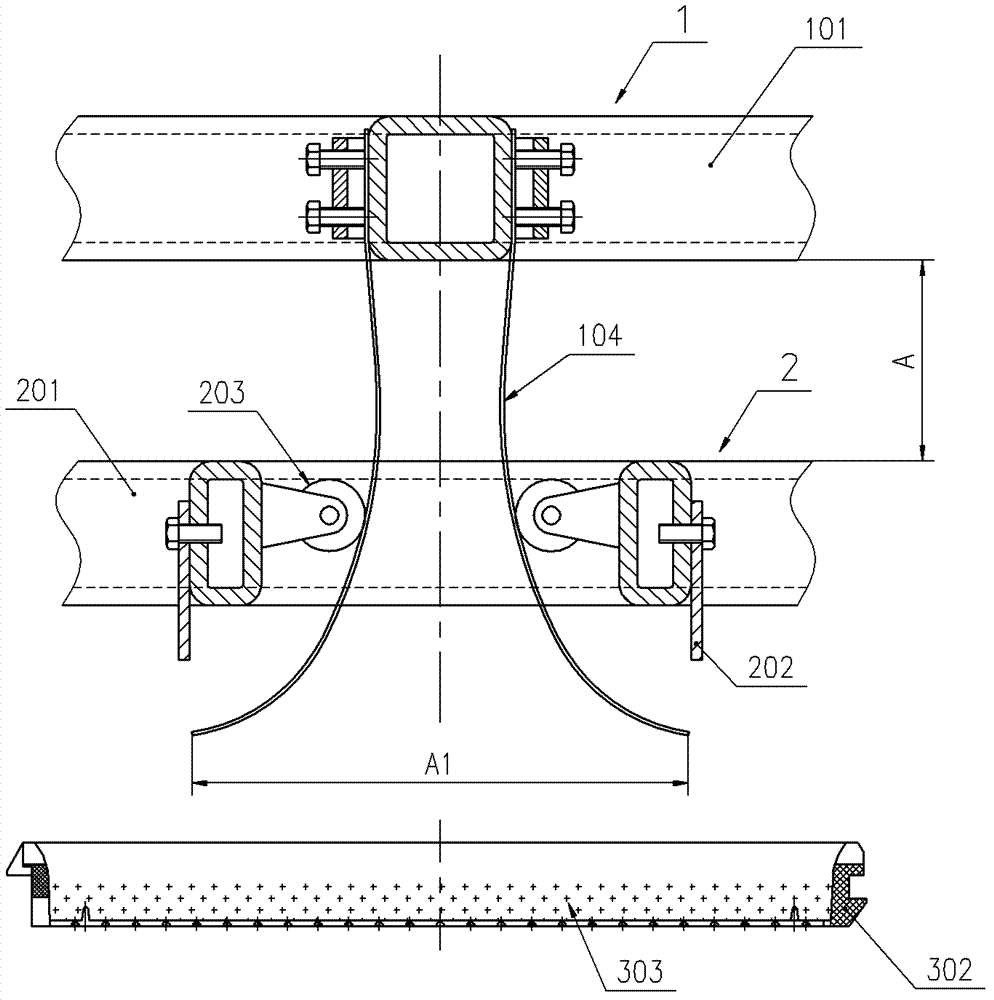

Cake fetching device for algae material processing

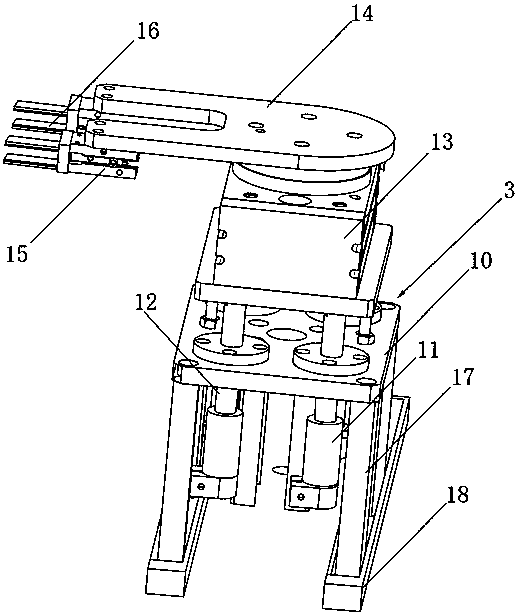

ActiveCN102763869AHigh degree of work automationWork reliablyFood preparationEngineeringMaterials processing

The invention provides a cake fetching device for algae material processing. The device comprises a first frame assembly, a second frame assembly, a cake fetching member and a rack. By mutual extrusion and extrusion relief motions of the claw-type cake fetching member installed on the first frame and an interacting member installed on the second frame, and with the cooperation of vertical movement and relative movement of the first and second frames, the lower end of the claw-type member spreads or contracts to fetch a material cake in a material tray, and the material cake is sent out of the unit through a discharging assembly. The device provided by the invention is one of the key technological devices for realizing operational automation of algae material processing units, and has technical characteristics of simple structure, reliable operation, stable performance and high degree of automation.

Owner:LIANYUNGANG FUAN LAVER MACHINE

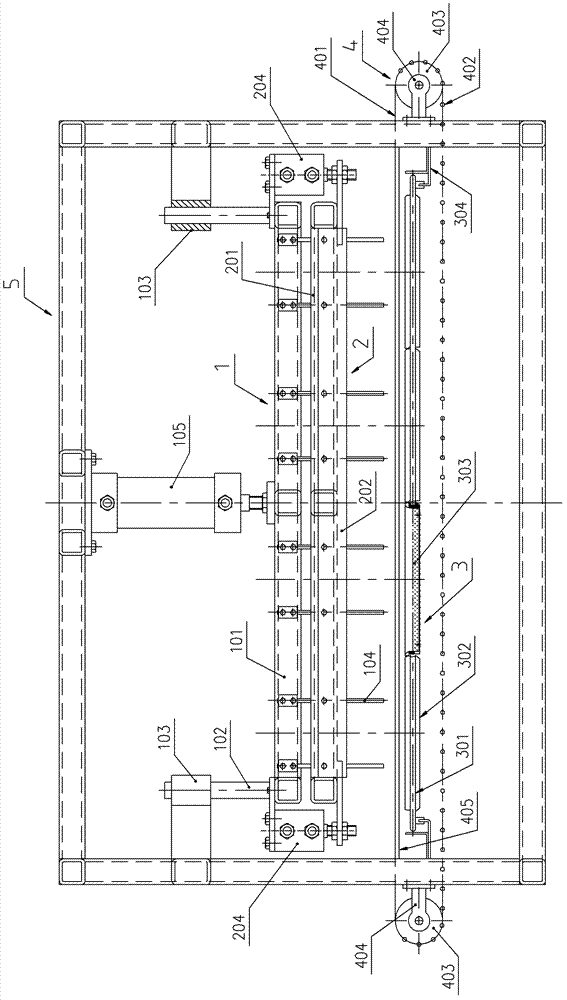

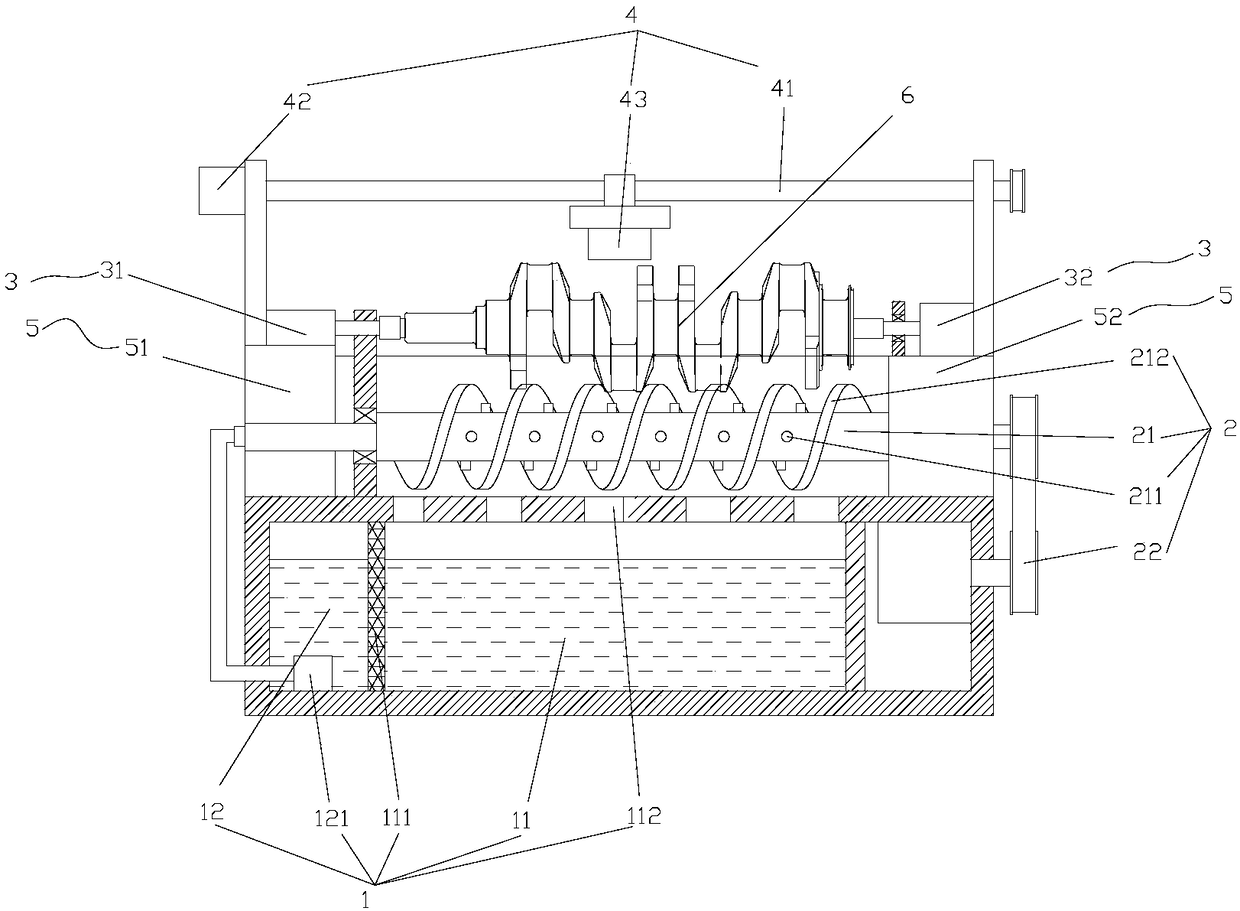

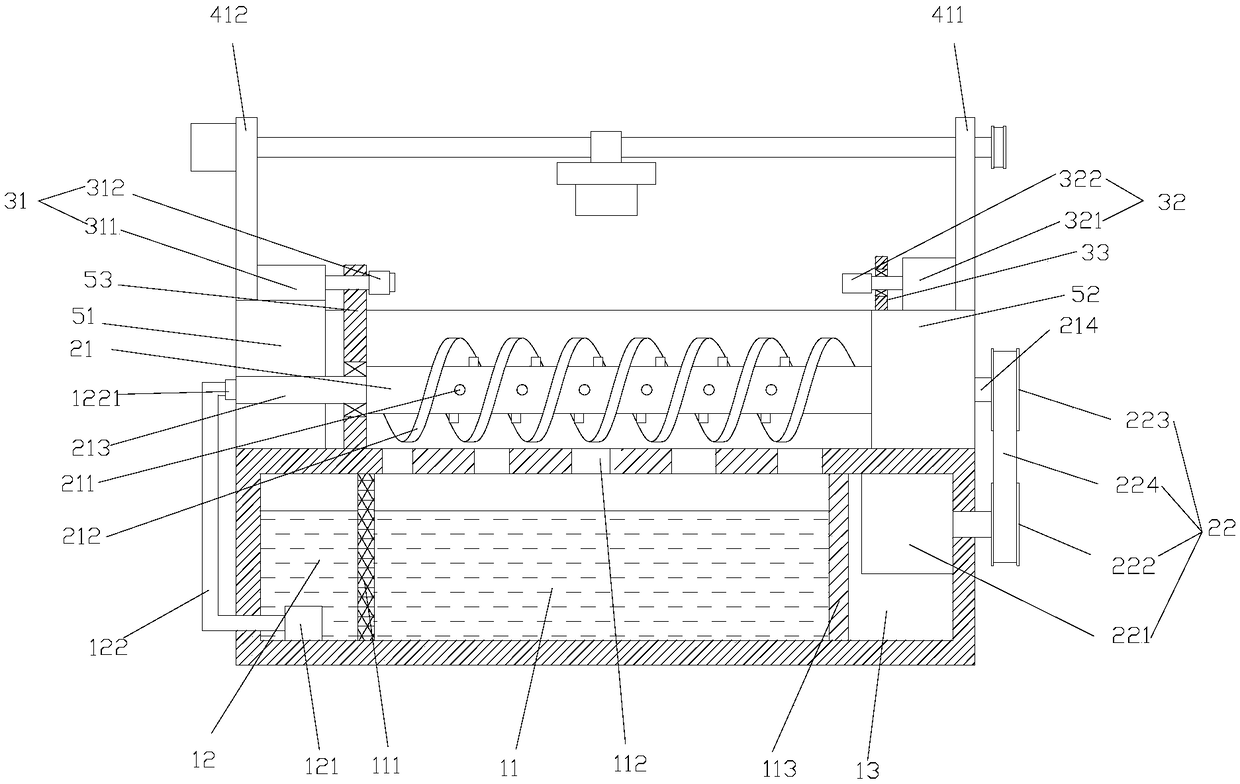

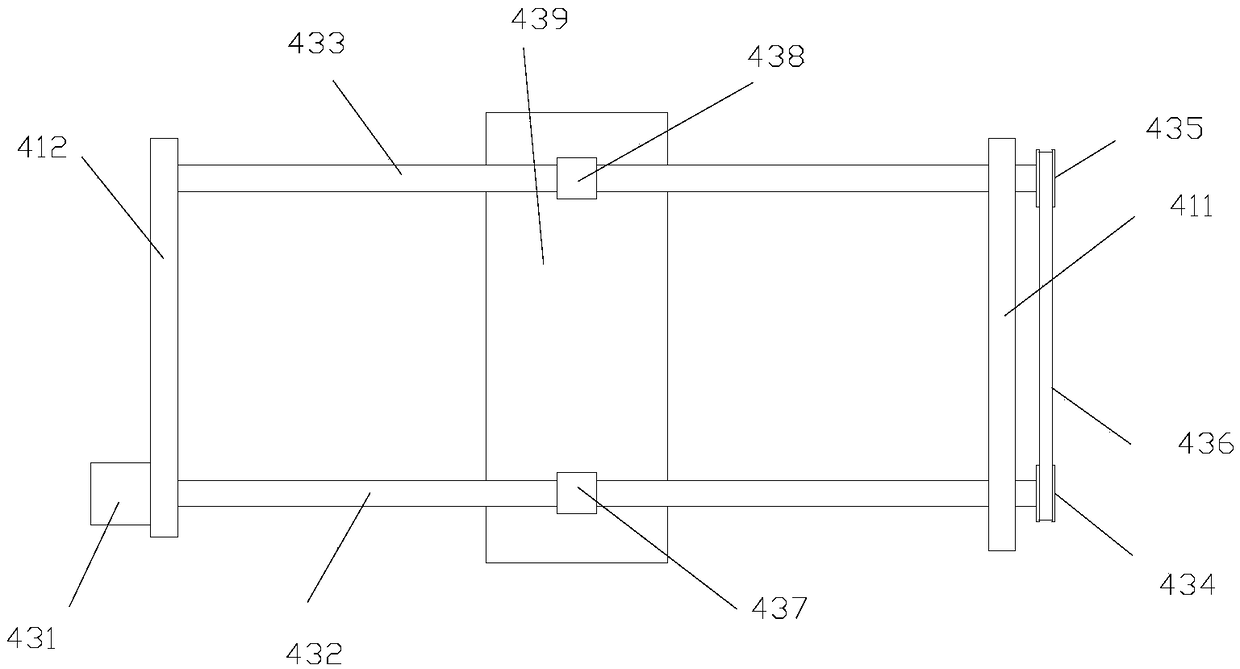

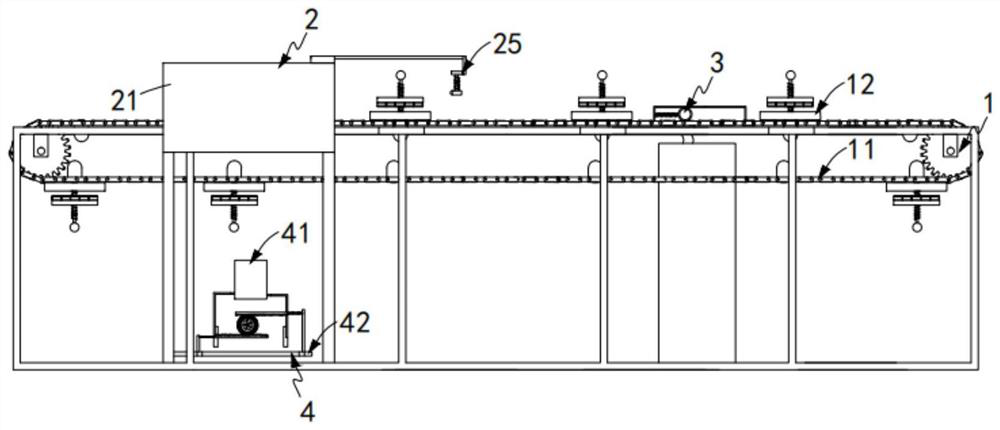

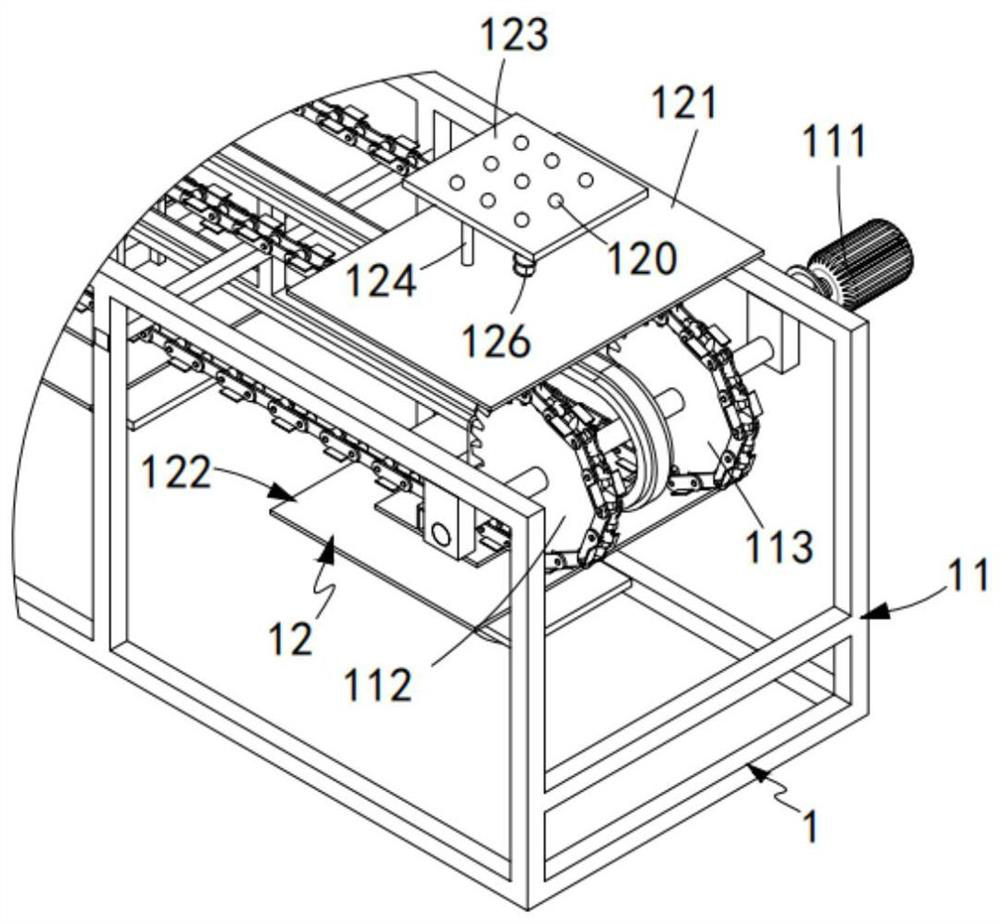

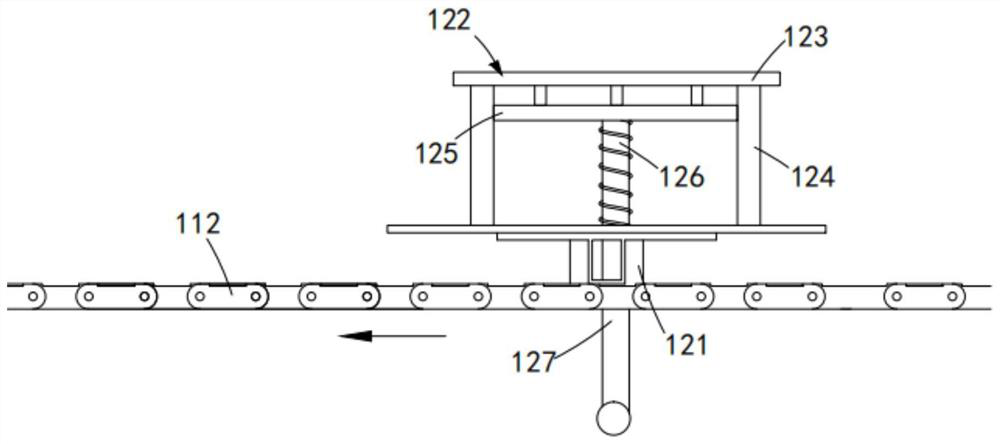

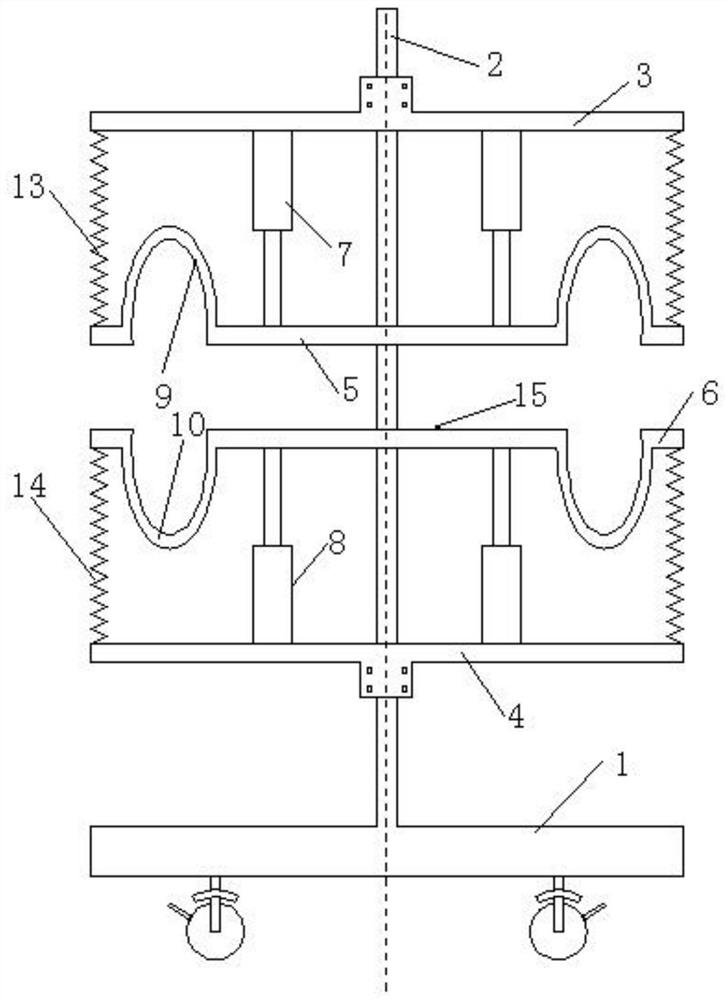

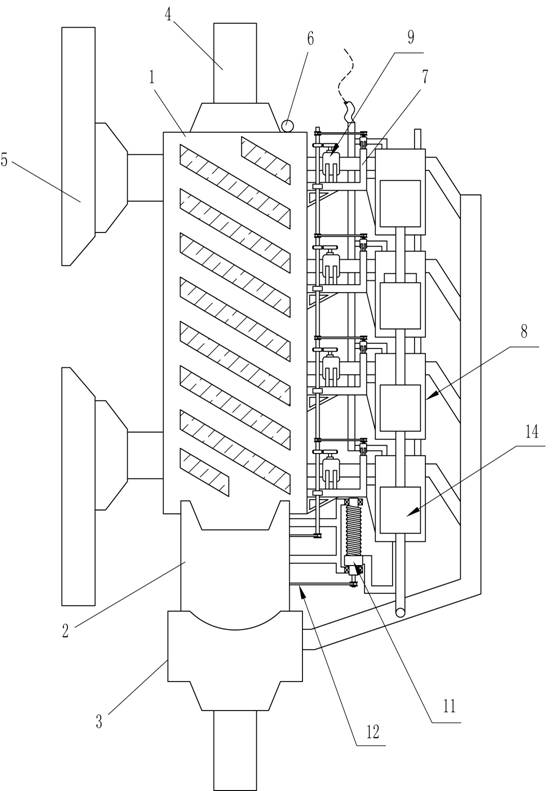

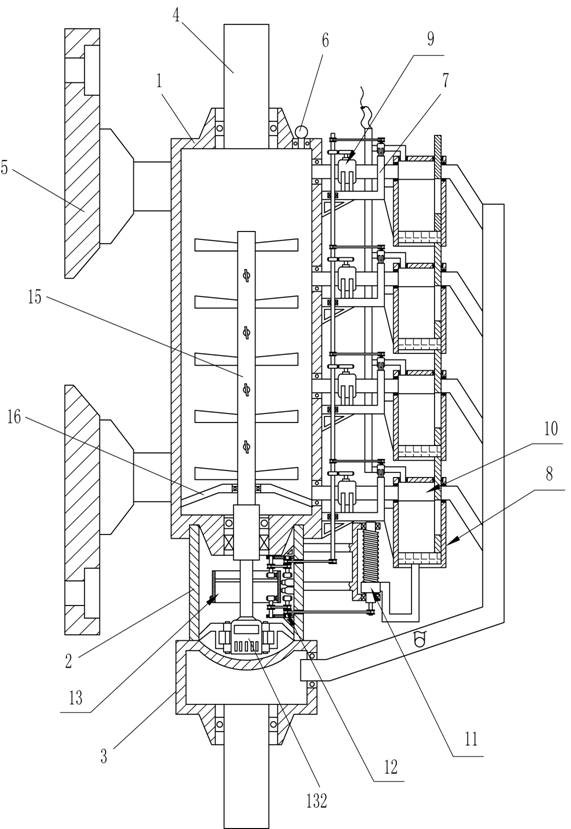

Washing and drying device and method for crankshaft of diesel engine

ActiveCN108787593AReduce processShorten the timeCleaning using liquidsHeating arrangementEngineeringDiesel engine

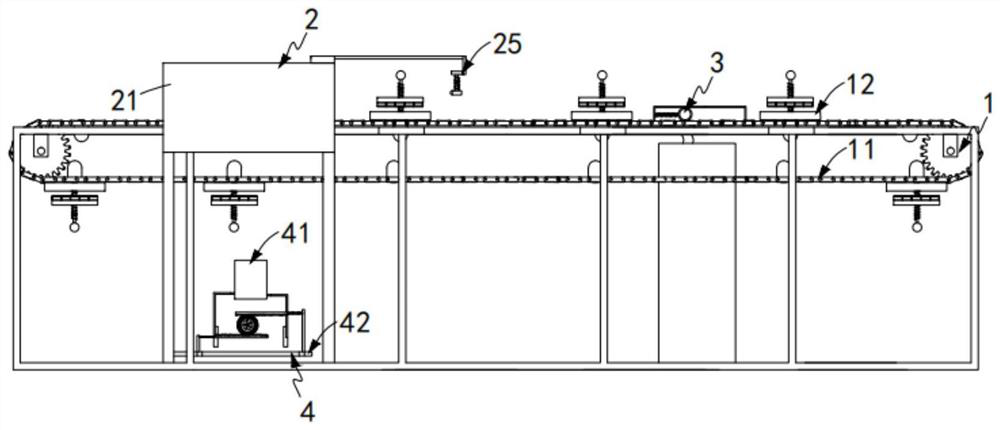

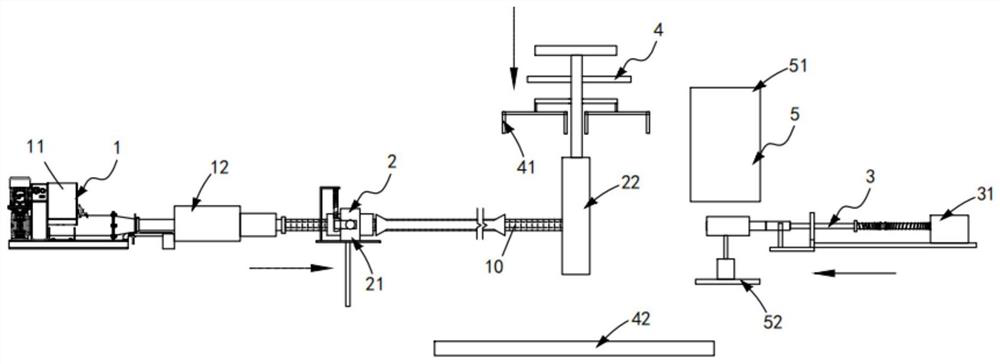

The invention discloses a washing and drying device and method for a crankshaft of a diesel engine. The washing and drying device comprises a shell, a washing device, clamping devices and a drying device, wherein the washing device can rotate circumferentially; the clamping devices are capable of clamping the two ends of the crankshaft and driving the crankshaft to rotate; the shell is of a box type structure with an opening on the top surface; the washing device is fixed on the shell and is horizontally arranged above the shell; the clamping devices are fixed above the shell and are horizontally arranged above the shell; and the drying device is higher than the clamping devices. The invention also discloses the drying method. The washing and drying device and method for the crankshaft ofthe diesel engine have the beneficial effects that the clamping devices are used for clamping the crankshaft; the washing device is used for washing the crankshaft; the drying device is used for drying the crankshaft; the secondary clamping is not needed; washing and drying are completed at a time; working procedures are saved; time is saved; the automation degree of work is high; and the operation is simple.

Owner:ANHUI QUANCHAI ENGINE

Environment-friendly sewage treatment equipment

ActiveCN112090167AReduce processing costsAvoid cloggingTreatment involving filtrationMultistage water/sewage treatmentSewageWaste water treatment plant

The invention discloses environment-friendly sewage treatment equipment which comprises a pressure pipe and a connecting box, wherein the pressure pipe and the connecting box are provided with a flowdividing device, a starting and stopping device, a removing device, a lifting device, a transmission device and a driving device; a connecting box is fixedly connected to one side of the pressure pipe, a communicating pipe is fixedly connected to the other side of the connecting box, external connecting pipes are connected into the communicating pipe and the other side in the pressure pipe in a sealed mode, a wall hanging frame is fixedly connected to one side of the pressure pipe, and a water pressure gauge is connected to the position, away from one side of the connecting box, of the pressure pipe in a sealed mode. At least one mounting frame is fixedly connected to the side, away from the wall hanging frame, of the pressure pipe. Through cooperation of the flow dividing device, the starting and stopping device, the removing device, the lifting device, the transmission device and the driving device, the efficiency in the sewage treatment process is improved, a pipeline cannot be blocked in the sewage conveying process, the environmental protection property is improved, and the workload of a sewage treatment plant is reduced.

Owner:河南正远化工有限公司

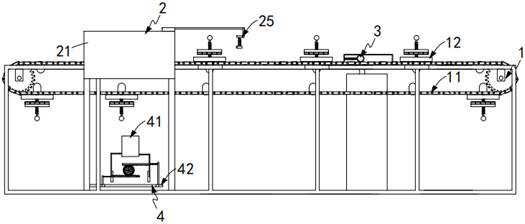

Bread production dryer with good drying effect

ActiveCN112535421AIncrease productionFast formingBaking ovenBakery productsStructural engineeringMechanical engineering

The invention relates to a bread production dryer with a good drying effect, which comprises a transmission mechanism, the transmission mechanism comprises a first transmission assembly and a bearingassembly; a drying mechanism which comprises a drying box, a positioning assembly, a first direction dividing assembly, wherein two sets of clamping assemblies symmetrically arranged on the two sidesof the direction dividing assembly, and a second direction dividing assembly arranged outside the drying box and matched with the clamping assemblies to conduct longitudinal direction dividing work; acore injection mechanism; and a packaging mechanism which comprises a bearing assembly arranged below the first transmission assembly and a bagging assembly arranged below the bearing assembly and used for packaging bread output from the bearing assembly. The technical problems that when old bread is packaged, the bread needs to be stacked in a bag manually, placed in sequence and then packaged,the working efficiency is low, and the yield is low are solved.

Owner:阜阳市家居乐食品有限公司

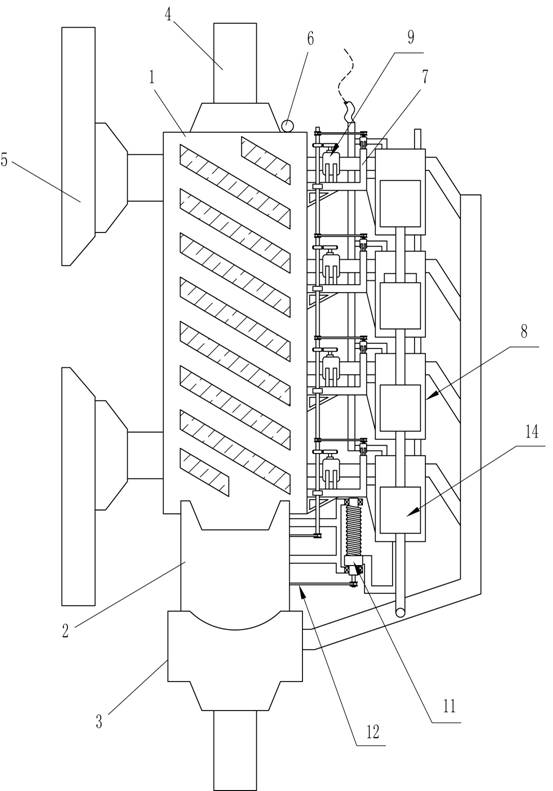

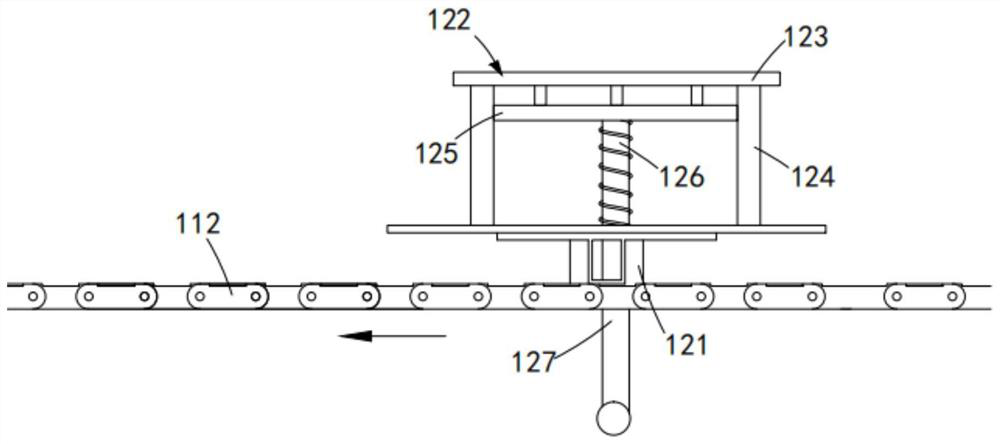

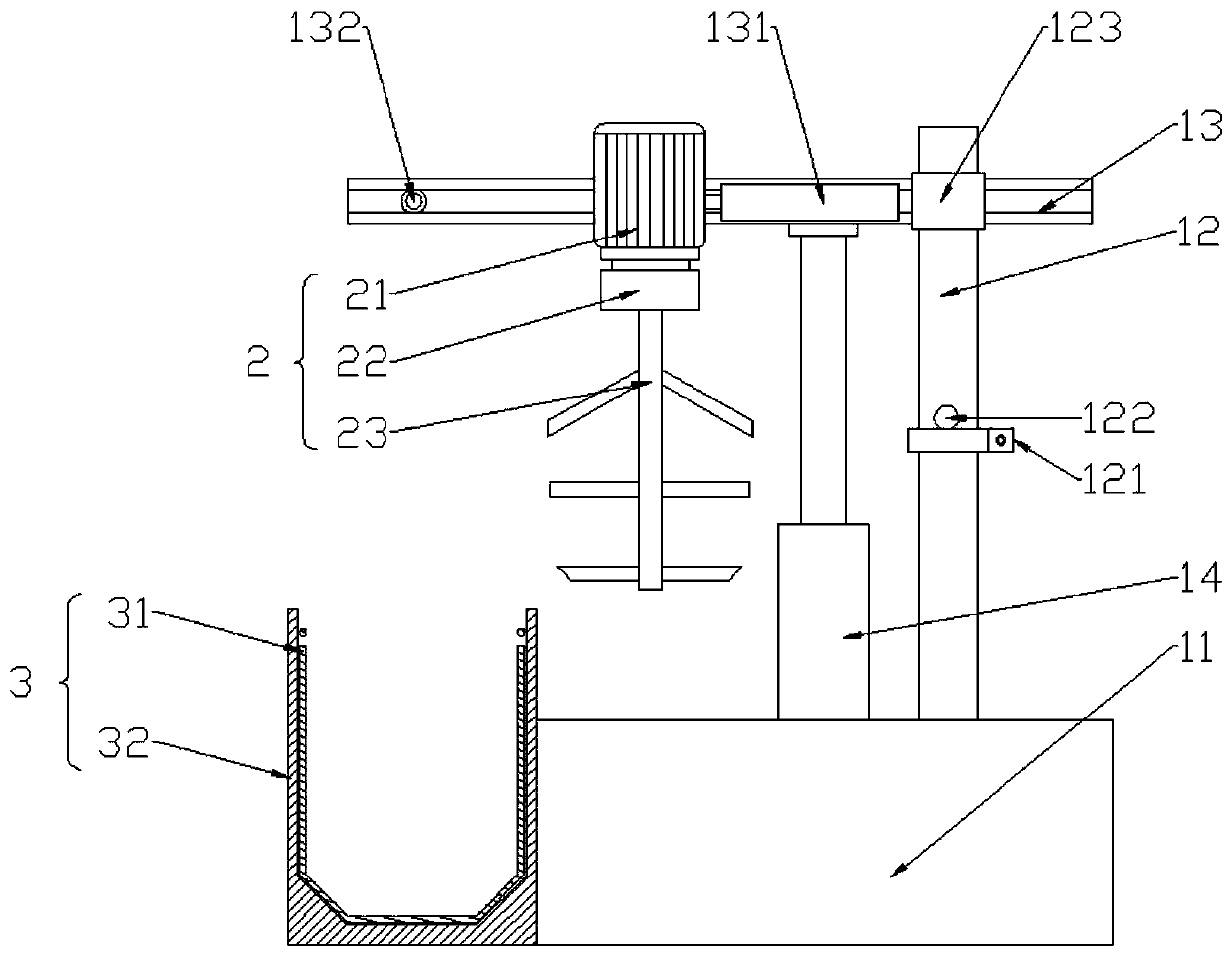

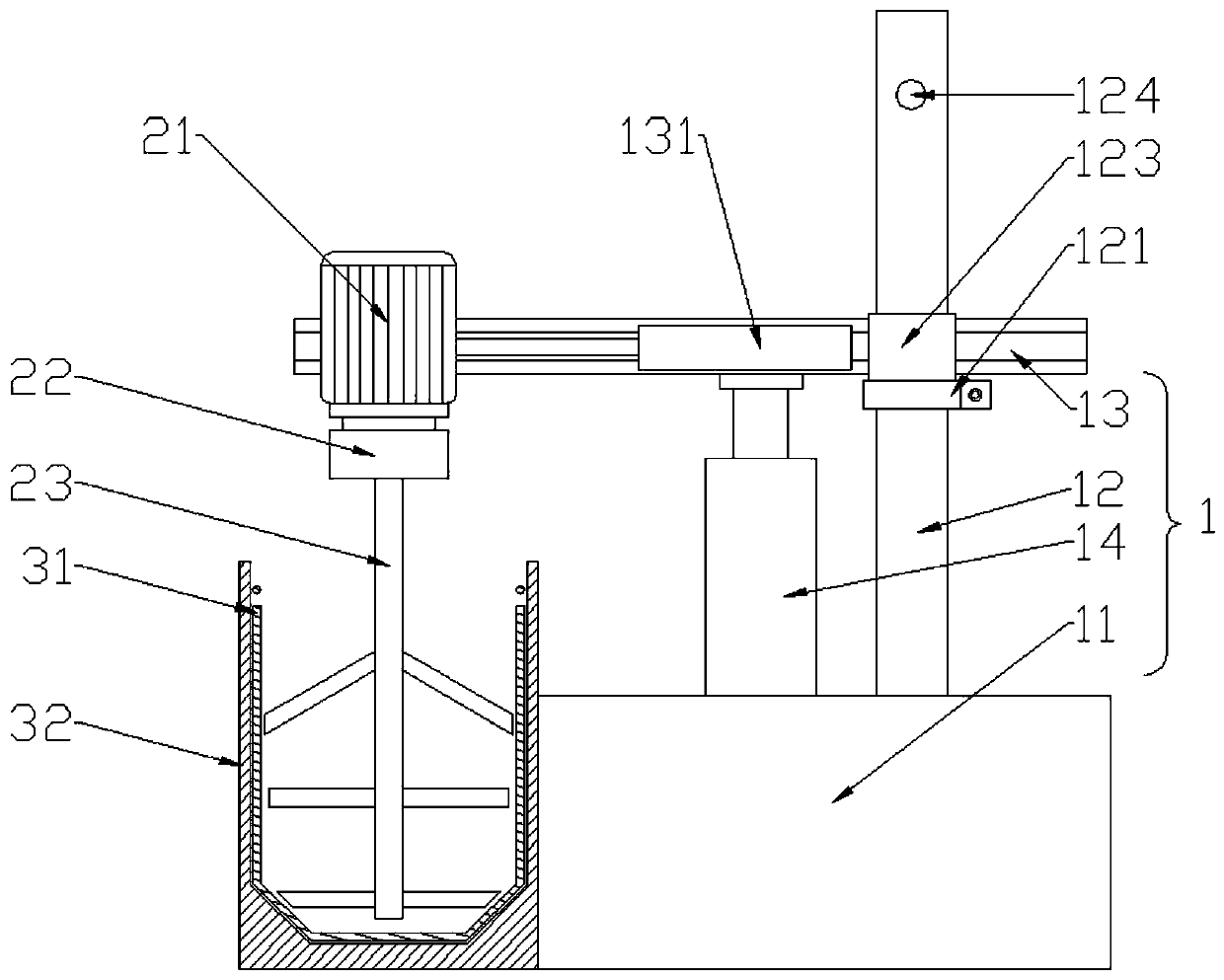

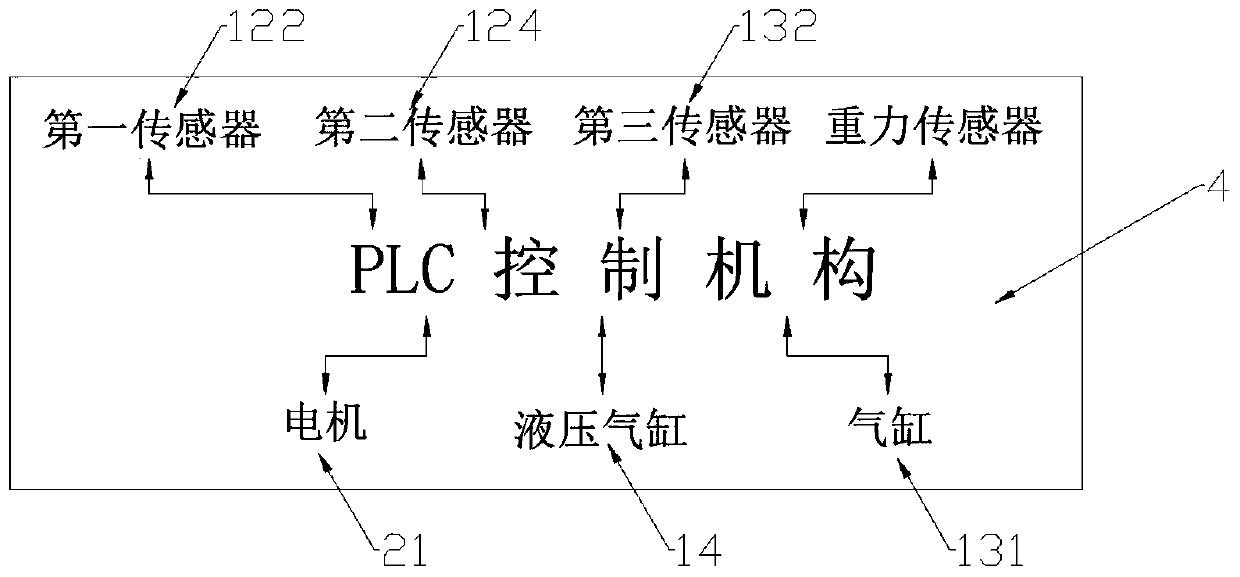

Mixing stirrer for medium-hardness heat vulcanized heat conduction silicone rubber and preparation process

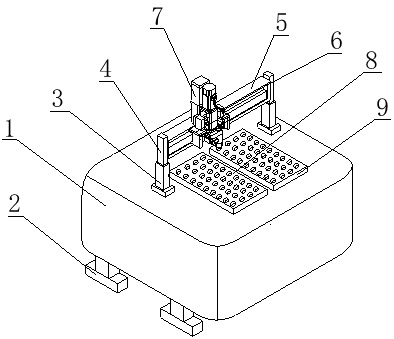

The invention discloses a mixing stirrer for medium-hardness heat vulcanized heat conduction silicone rubber and a preparation process. The mixing stirrer comprises a machine frame, a stirring assembly and a stirring object container assembly, wherein the stirring assembly is arranged on the machine frame, the stirring object container assembly is arranged on the side, close to the stirring assembly, of the machine frame, the machine frame comprises a base, a guide column, a moving beam assembly and a hydraulic air cylinder, the guide column is perpendicularly arranged at the upper end part ofthe base, the moving beam assembly is perpendicularly connected with the guide column, the hydraulic air cylinder is arranged at the upper part of the base, the upper end part of the hydraulic air cylinder is connected with the moving beam assembly, the stirring object container assembly comprises a stirring barrel and a stirring barrel base, and the stirring barrel is arranged inside the stirring barrel base. According to the mixing stirrer for the medium-hardness heat vulcanized heat conductive silicone rubber and the preparation process, the machine and barrel separation arrangement is adopted so that the stirring barrel can be conveniently cleaned, the application of multiple induction devices, the stirring process and the time control are fixed, and the stirring effect and the safetyare improved.

Owner:苏州歌诗夫新材料有限公司

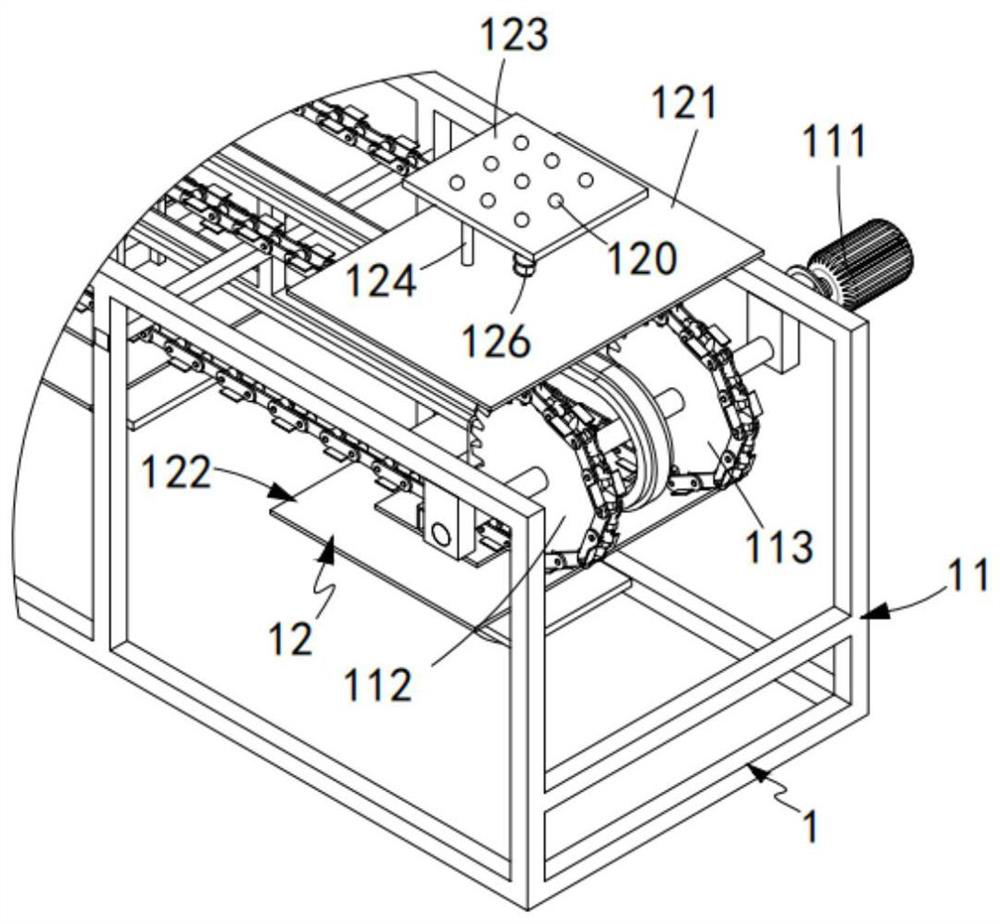

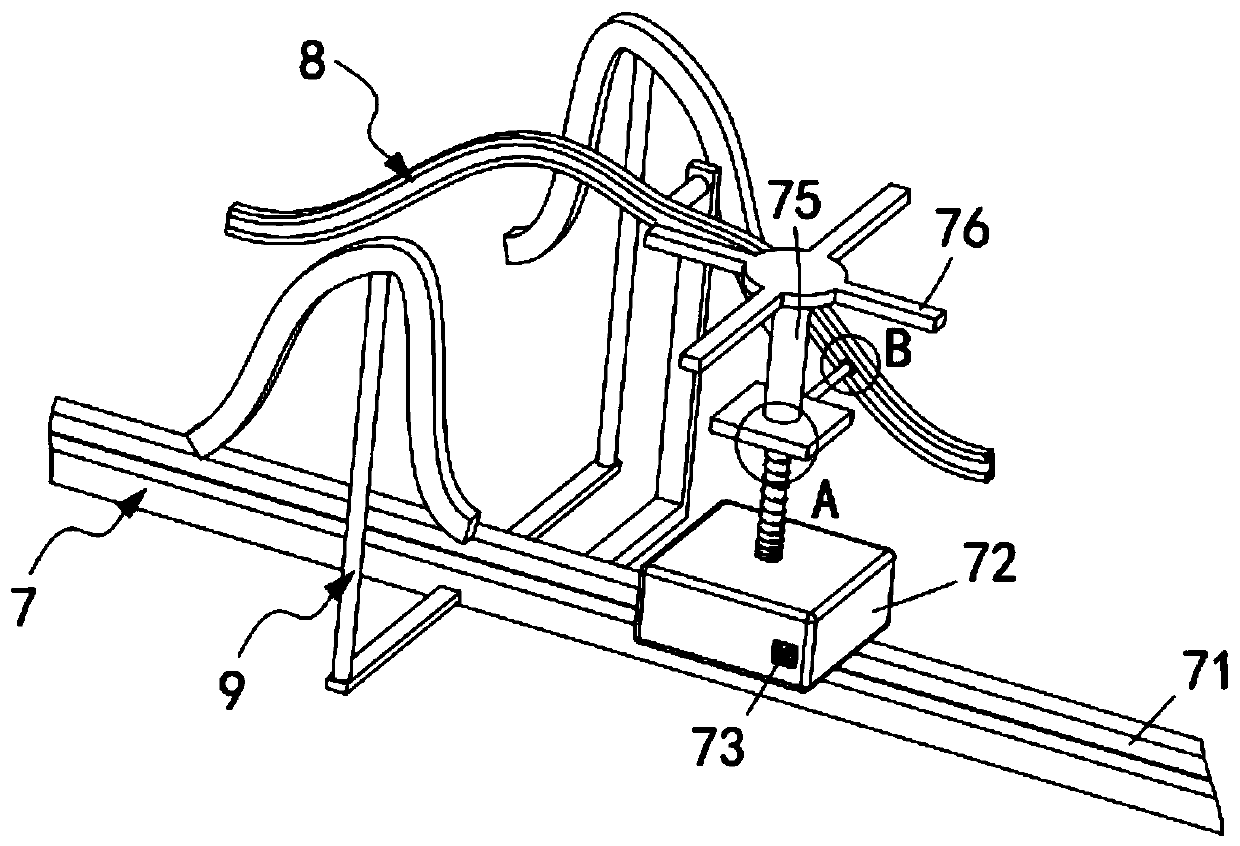

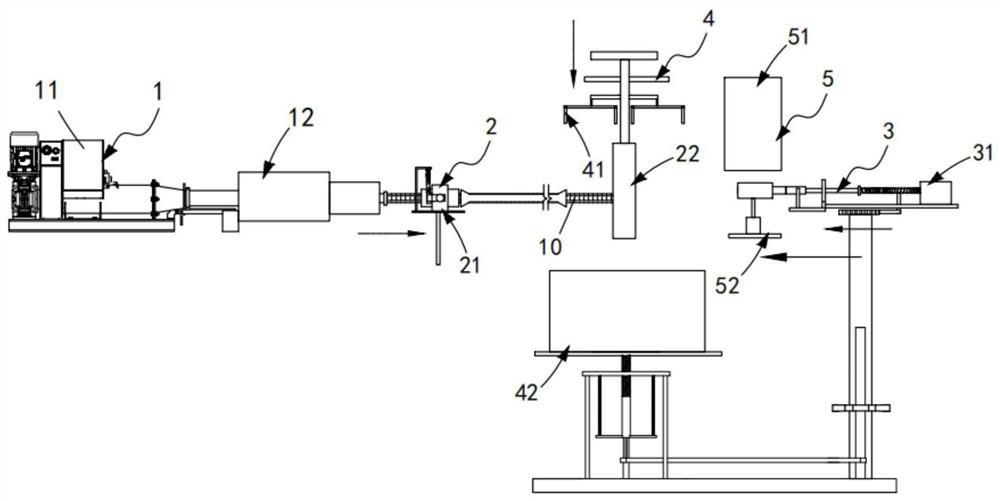

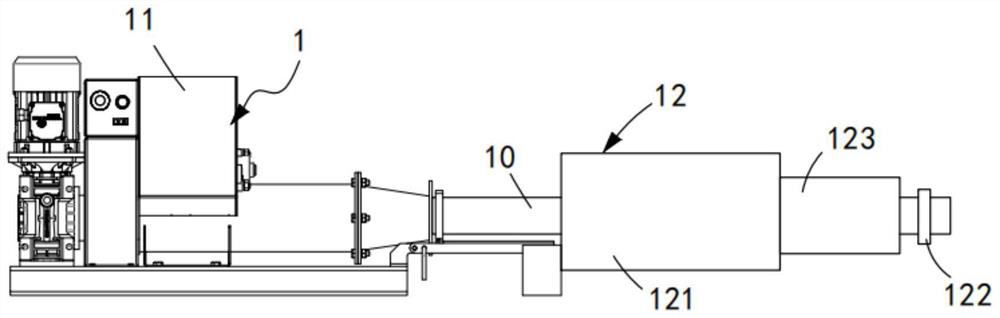

Continuous packaging equipment for furniture gap blocking rubber strips

InactiveCN112743792AEasy to moveHigh degree of work automationFilament handlingStacking articlesEngineeringStacker

The invention relates to continuous packaging equipment for furniture gap blocking rubber strips. The continuous packaging equipment for the furniture gap blocking rubber strips comprises a conveying mechanism, a traction mechanism, a winding mechanism, a stacking mechanism and a mold loading mechanism, wherein the conveying mechanism comprises an extruder and a cooling assembly; the traction mechanism comprises a clamping assembly and a supporting assembly; the winding mechanism comprises a hoop assembly and a cutting assembly; a hooping mold is placed on the hoop assembly; the stacking mechanism comprises a downward pushing assembly arranged above the supporting assembly and a stacking assembly matched with the downward pushing assembly and located below the supporting assembly; and the mold loading mechanism comprises a mold storage assembly arranged above the hoop assembly and a conveying assembly used for driving the mold storage assembly to automatically enter the hoop assembly. The continuous packaging equipment for the furniture gap blocking rubber strips solves the technical problems that when rubber and plastic strips are packaged, shutdown is needed for cutting, a new roller is replaced for winding work after cutting, the machine is shut down to work, the working time is wasted, the machine is prone to damage, the service life is short, and meanwhile, the working efficiency is low.

Owner:浙江笙龙家具有限公司

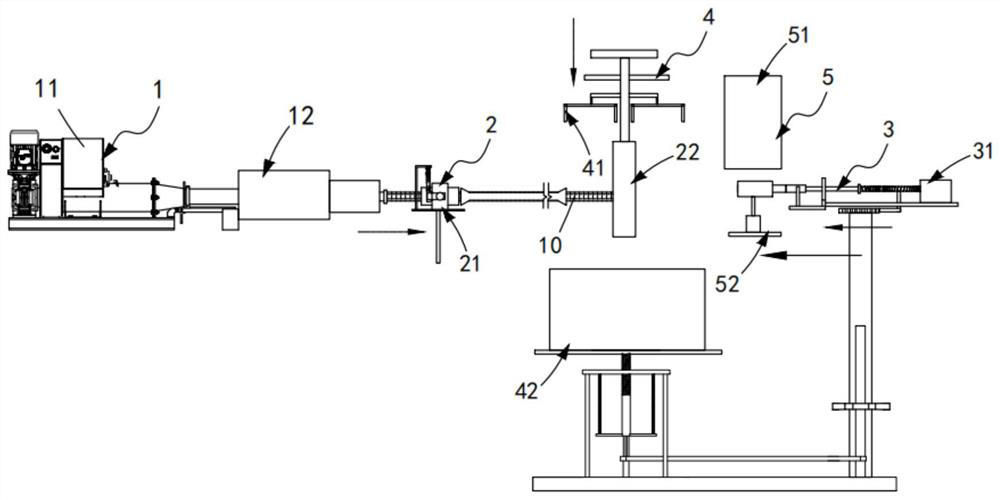

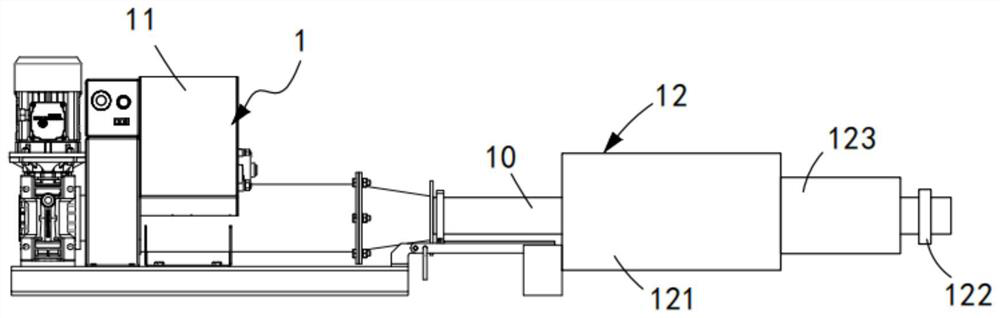

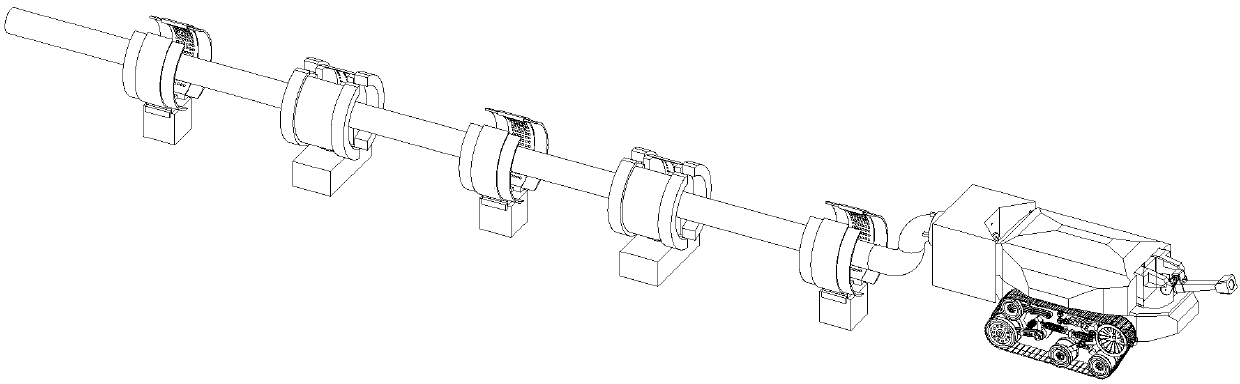

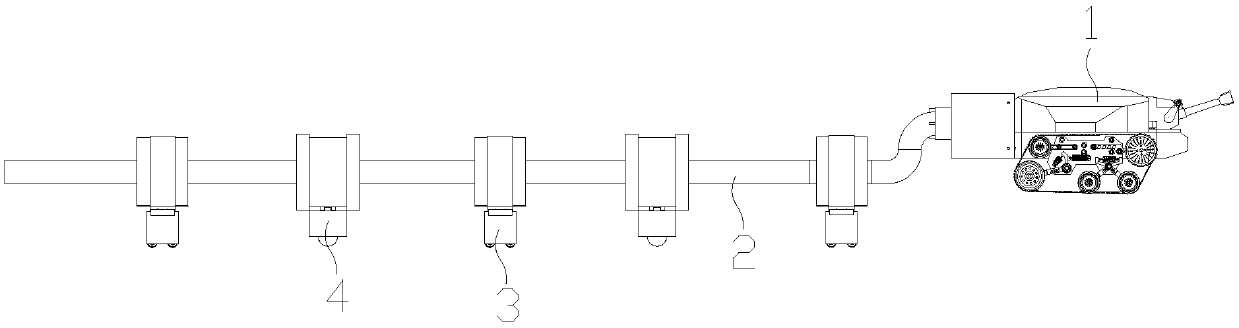

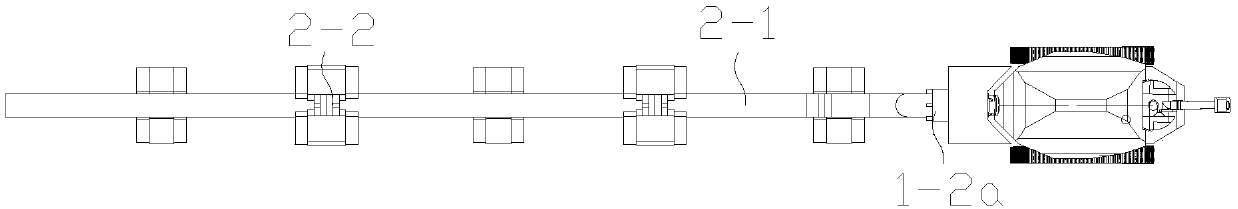

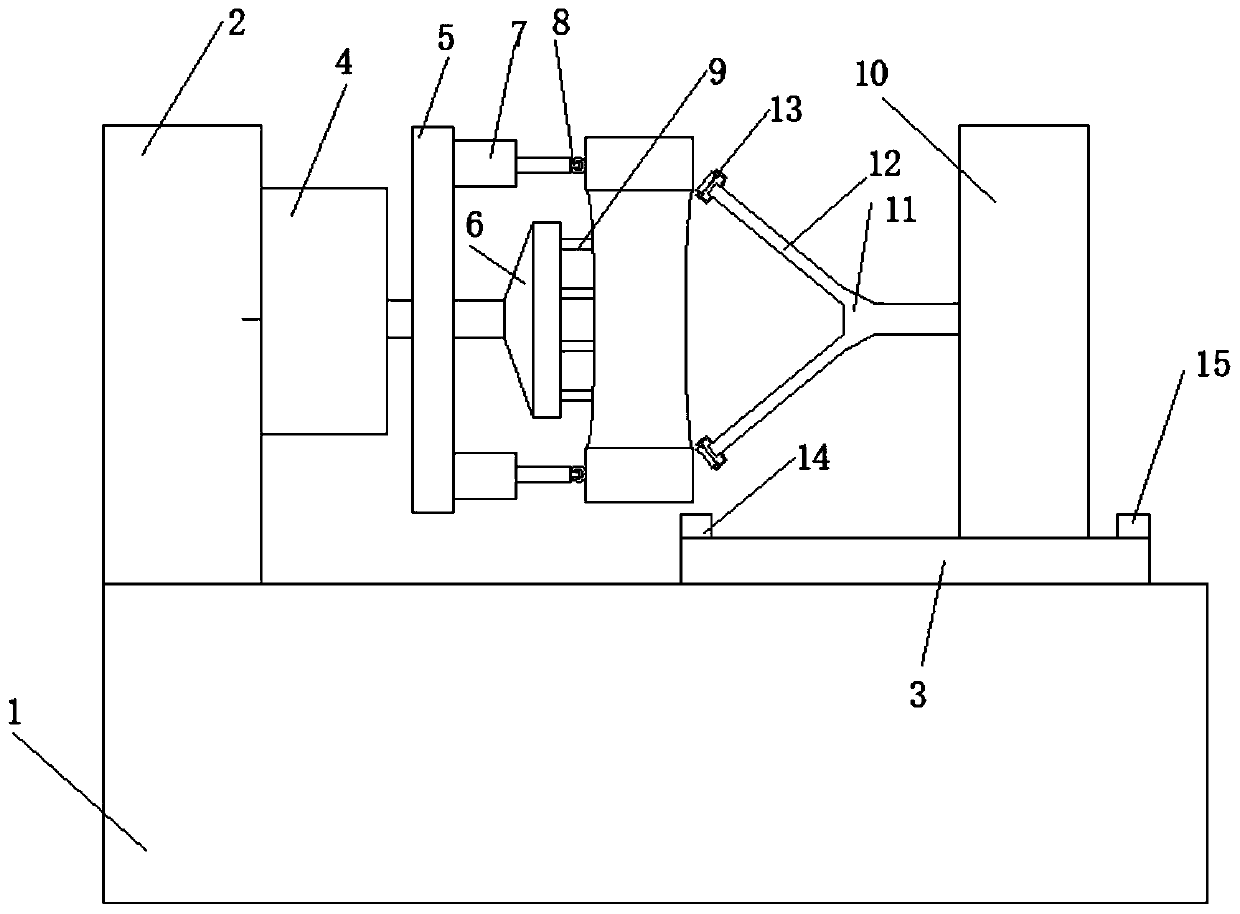

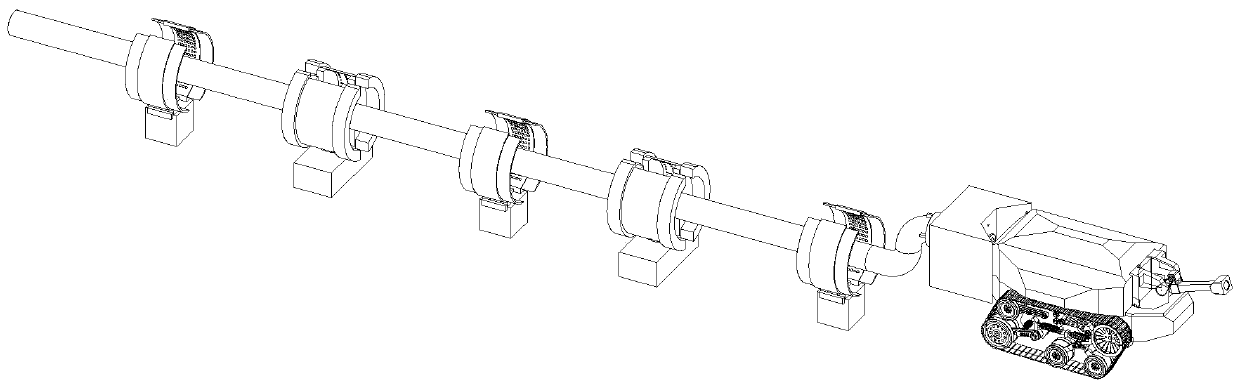

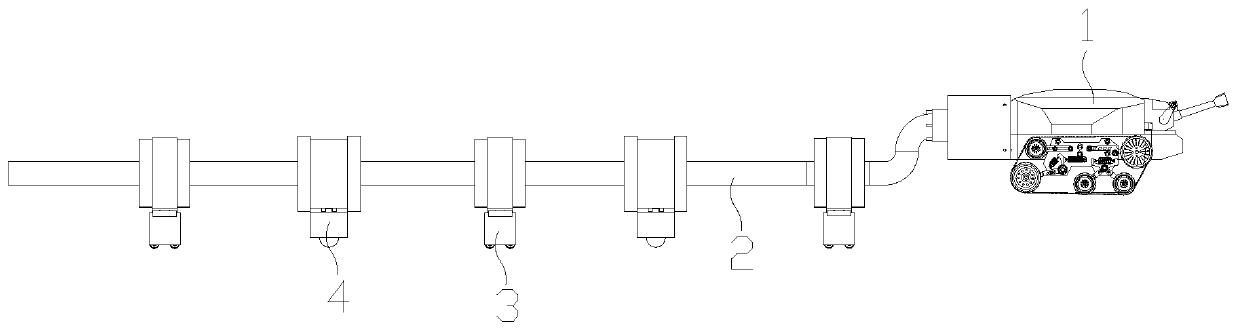

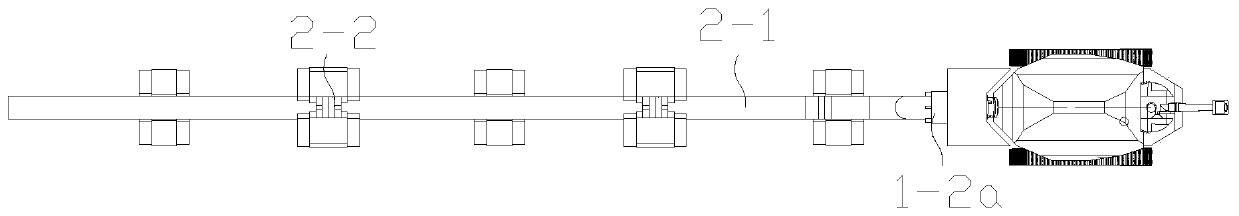

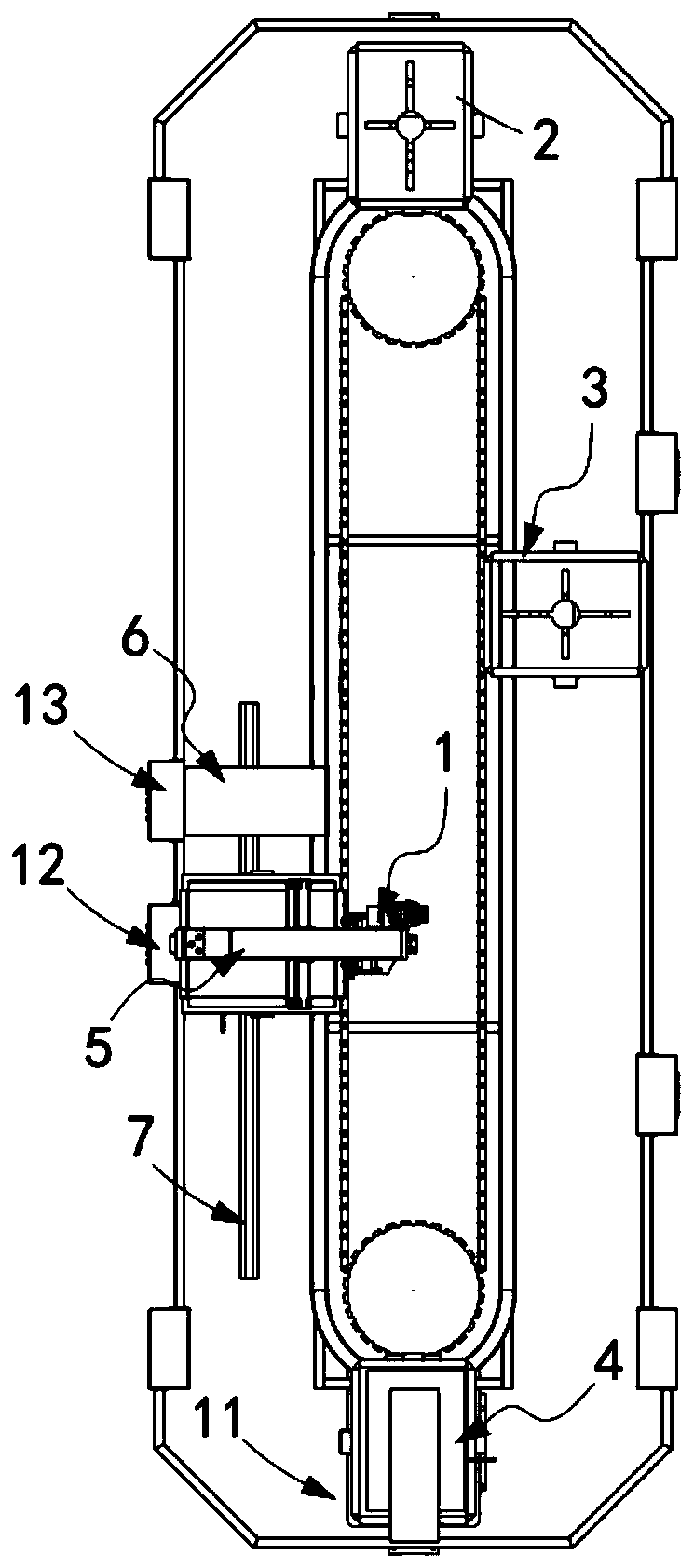

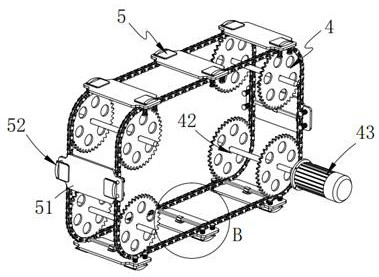

Working method of firefighting robot system with orientation real-time adjusting function

ActiveCN109589524AImprove mobilityHigh degree of work automationFire rescueRobotic systemsFirefighting

The invention relates to a working method of a firefighting robot system with an orientation real-time adjusting function. The working method comprises a step that water hose active displacement mechanisms and water hose passive displacement mechanisms are uniformly dispersed and arranged along a fire hose filled with water, and a step that a firefighting robot controls the water hose active displacement mechanisms and the water hose passive displacement mechanisms to carry out direction conversion on the fire hose filled with water. The working method improves the maneuverability of robot deployment, increases the automation degree of the work of the firefighting robot effectively, reduces the risk of injury caused by manual operation, and meanwhile reduces the operation cost of the firefighting robot.

Owner:SHANDONG GUOXING SMARTECH CO LTD +1

Device for disassembling automobile tires

The invention belongs to the field of tire disassembling devices, and discloses a device for disassembling automobile tires. A motor fixing device and a moving device are arranged at the upper end ofa device body, and a horizontally-arranged rotating motor is fixedly connected to one side, close to the moving device, of the motor fixing device; a first connecting disc is arranged in the middle ofa power output shaft of the rotating motor in a sleeving mode, the tail end of the power output shaft of the rotating motor is connected with a second connecting disc, and the first connecting disc and the second connecting disc are vertically arranged; one end, far away from the rotating motor, of the first connecting disc is connected with telescopic air cylinders, and first rolling wheels arearranged at the tail ends of the telescopic air cylinders; one end face, far away from the rotating motor, of the second connecting disc is provided with screw rods; the upper end of the moving deviceis connected with a connecting rod fixing device in a sliding mode; and one end of a connecting rod is connected with a first fixing rod, the first fixing rod is connected with two second fixing rods, and the second fixing rods are connected with second rolling wheels.

Owner:合肥海川汽车部件系统有限公司

The working method of the fire-fighting robot system with the function of real-time adjustment of orientation

ActiveCN109589524BImprove mobilityHigh degree of work automationFire rescueRobotic systemsControl engineering

The invention relates to a working method of a firefighting robot system with an orientation real-time adjusting function. The working method comprises a step that water hose active displacement mechanisms and water hose passive displacement mechanisms are uniformly dispersed and arranged along a fire hose filled with water, and a step that a firefighting robot controls the water hose active displacement mechanisms and the water hose passive displacement mechanisms to carry out direction conversion on the fire hose filled with water. The working method improves the maneuverability of robot deployment, increases the automation degree of the work of the firefighting robot effectively, reduces the risk of injury caused by manual operation, and meanwhile reduces the operation cost of the firefighting robot.

Owner:SHANDONG GUOXING SMARTECH CO LTD +1

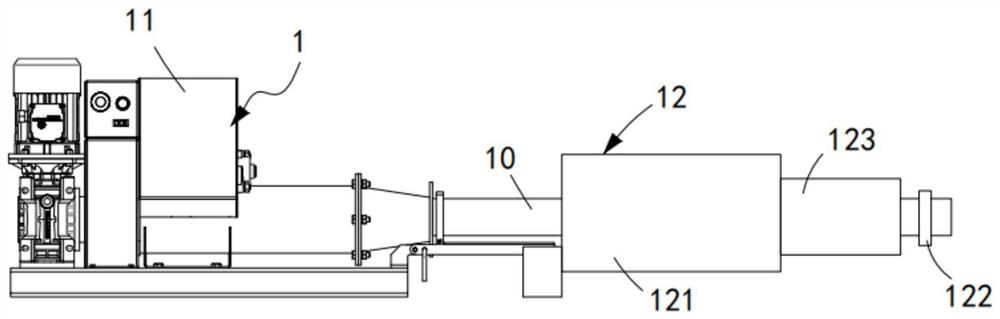

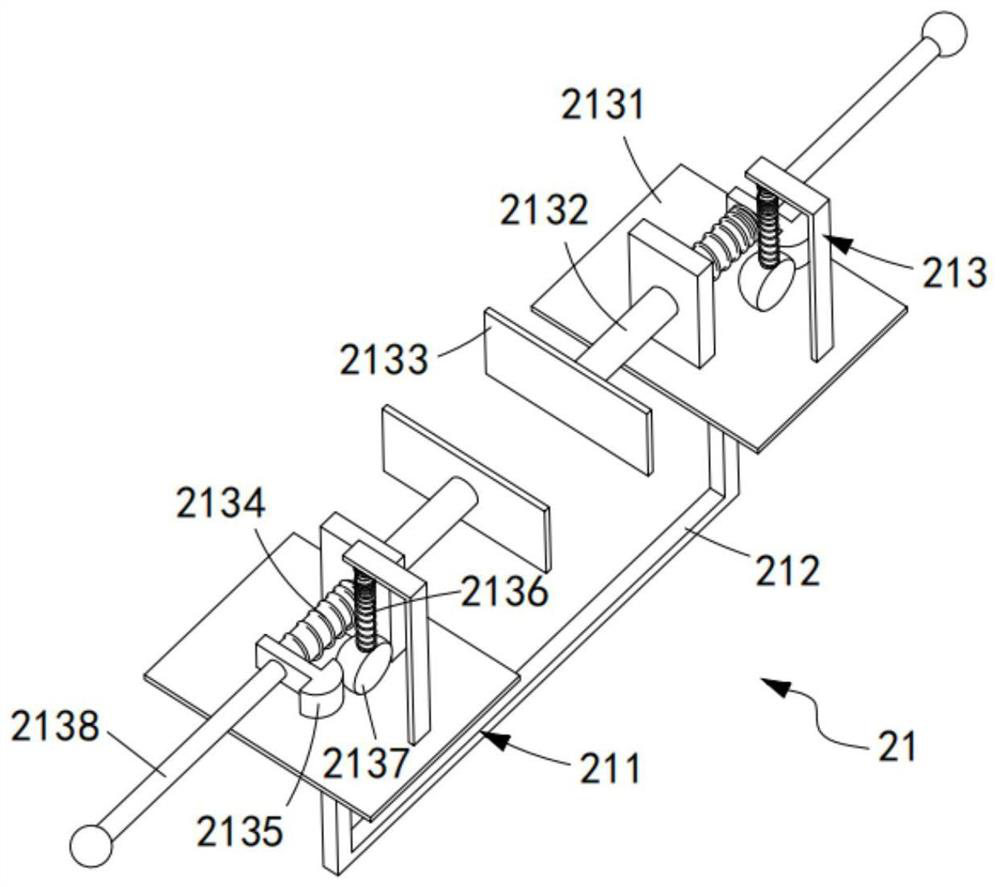

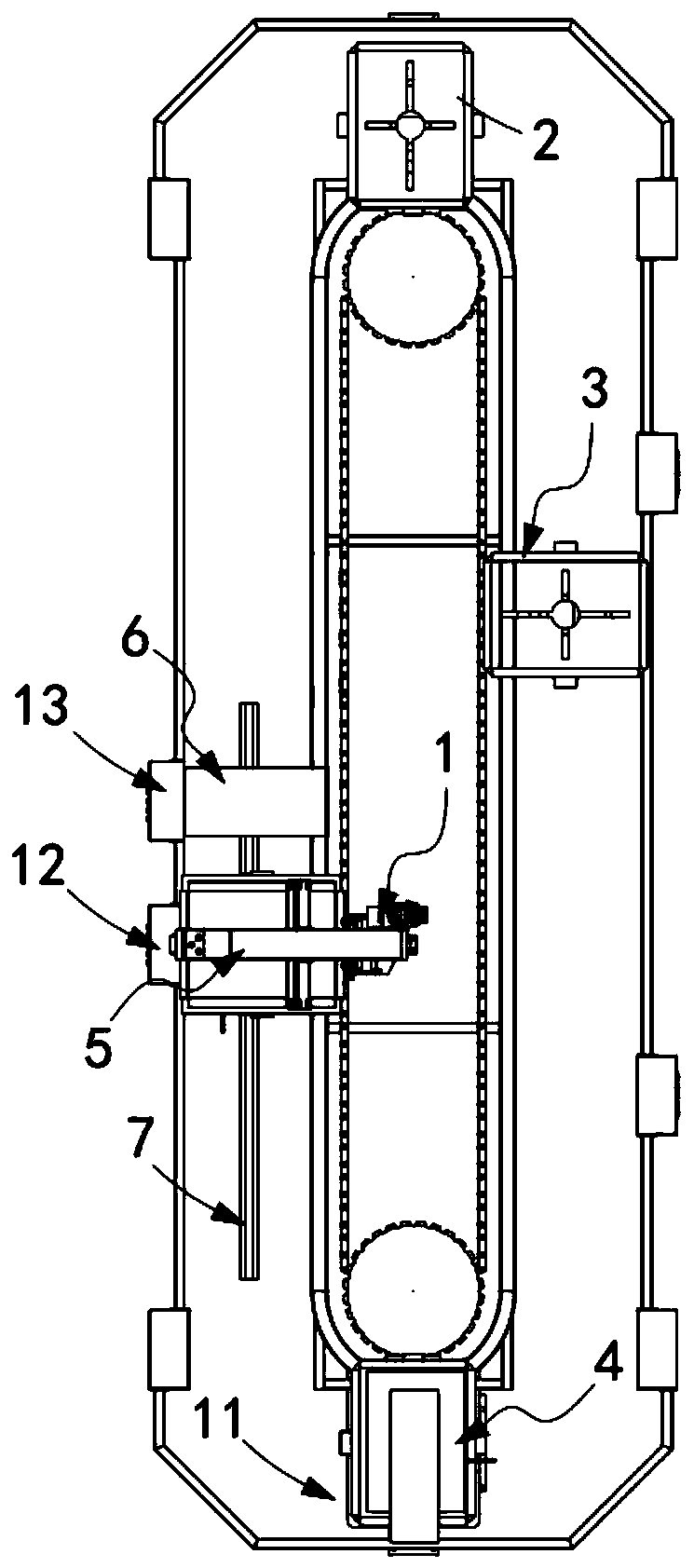

Color printing machine for fabrics

ActiveCN111114105AHigh degree of work automationContinuous workScreen printersPrinting press partsPhysicsColor printing

The invention relates to a color printing machine for fabrics. The color printing machine for the fabrics comprises a printing machine body, multiple fabric receiving plates arranged at equal intervals in the conveying direction of the printing machine body, hasp mechanisms arranged on the fabric receiving plates, a flattening mechanism arranged on an input end of the printing machine body, a printing mechanism arranged behind the flattening mechanism and a drying mechanism arranged behind the printing mechanism. A filling mechanism matched with the fabric receiving plates and a first controlmechanism for driving the filling mechanism to move up and down in the vertical direction are arranged below the printing mechanism. A second control mechanism for driving the hasp mechanisms to moveup and down in the vertical direction is arranged below the drying mechanism. The color printing machine for the fabrics solves the problem that since the fabrics are in a tensioning state for a longtime when the fabrics are conveyed, the elasticity of T-shirts is influenced.

Owner:昆山洁宏无纺布制品有限公司

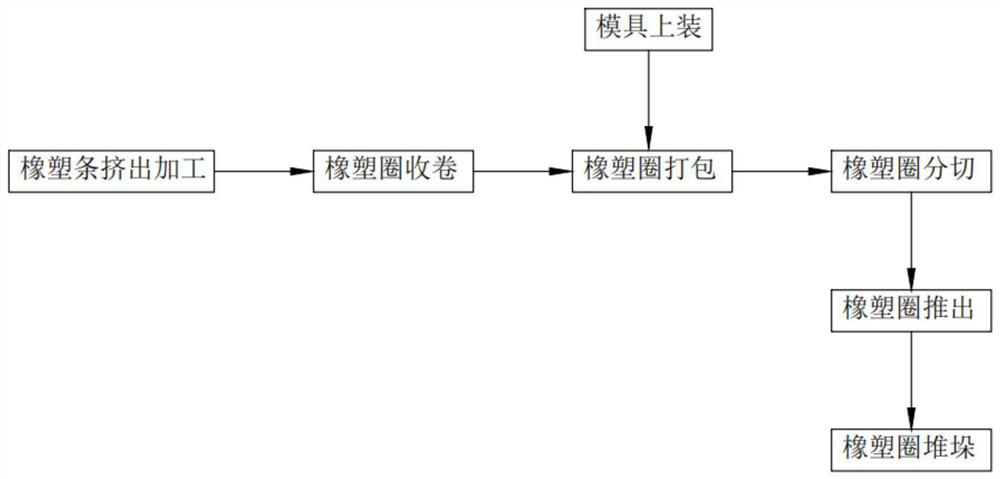

Furniture gap blocking rubber strip winding process

InactiveCN112722933ARealize automatic winding workAvoid towing workStacking articlesDomestic articlesWork timeComposite material

The invention relates to a furniture gap blocking rubber strip winding process. The furniture gap blocking rubber strip winding process comprises the steps of 1, extruding and machining rubber and plastic strips; 2, rolling rubber and plastic rings; 3, mounting a mold; 4, packaging the rubber and plastic rings; 5, slitting the rubber and plastic rings; 6, pushing out the rubber and plastic rings; and 7, stacking the rubber and plastic rings; According to the furniture gap blocking rubber strip winding process, the technical problems that the machine is shut down to cause waste of work time and is prone to damage, the service life is short, and meanwhile, the work efficiency is low because shutdown is needed for cutting and new rollers are arranged for winding after cutting when the rubber and plastic strips are packaged are solved.

Owner:浙江笙龙家具有限公司

A device for dismounting an automobile tire

The invention belongs to the field of tire removal devices and discloses a device for removing automobile tires; the upper end of the device body is provided with a motor fixing device and a moving device, and the side of the motor fixing device close to the moving device is fixedly connected with a horizontally arranged Rotating motor, the middle part of the power output shaft of the rotating motor is covered with a first connection plate, and the end of the power output shaft of the rotating motor is connected with a second connection plate, and the first connection plate and the second connection plate The disk is vertically arranged, and the end of the first connection disk away from the rotating motor is connected with a telescopic cylinder, and the end of the telescopic cylinder is provided with a first scroll wheel; the end of the second connection disk away from the rotating motor is provided with a screw; the upper end of the mobile device is slidably connected with a connecting rod fixing device, one end of the connecting rod is connected with a first fixing rod, and the first fixing rod is connected with two second fixing rods, and the second fixing rod A second scroll wheel is attached.

Owner:合肥海川汽车部件系统有限公司

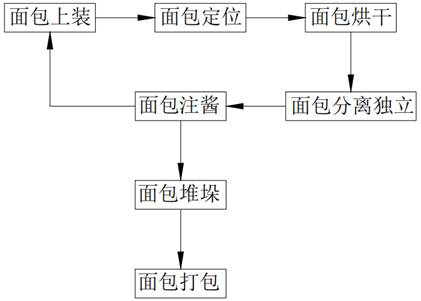

A kind of small bread production process

ActiveCN112640925BHigh degree of automation and continuousIncrease productionBaked article fillingPackagingProcess engineeringFood science

The invention relates to a small bread production process, comprising step 1, topping the bread; step 2, positioning the bread; step 3, drying the bread; step 4, separating and independent the bread; step 5, filling the bread with sauce; step 6, stacking the bread Step 7, bread packing; the present invention solves the technical problem that when old bread is packed, it is necessary to manually stack the bread in the bag, put it in successively and then pack it, and the work efficiency is low and the yield is low.

Owner:阜阳市家居乐食品有限公司

A drying machine for small bread production

ActiveCN112535421BIncrease productionFast formingBaking ovenBakery productsProcess engineeringMechanical engineering

Owner:阜阳市家居乐食品有限公司

Household sofa bed back cushion processing and forming equipment

ActiveCN114031030AQuality improvementHigh degree of work automationUpholstery manufactureButton pressingIndustrial engineering

The invention relates to household sofa bed back cushion processing and forming equipment. The equipment comprises a cotton filling mechanism, a forming mechanism and a collecting box body; and a bolster is clamped by the clamping mechanism installed on the conveying mechanism to sequentially pass through the cotton filling mechanism to complete automatic cotton filling work, then the bolster is transmitted to the forming mechanism to complete silk cotton scattering work after cotton filling, and finally the bolster is transmitted to the collecting box to complete automatic falling work of the formed bolster. The forming mechanism comprises a sewing assembly installed above the conveying mechanism, a flapping assembly in synchronous transmission with the sewing assembly and a button punching assembly for automatically carrying out button pressing on the bolster after sewing work is completed by the sewing assembly. The technical problems that cotton filling and sewing work needs to be completed for throw pillows of any structure, due to the fact that sewing is performed in two procedures after cotton filling, the cotton running phenomenon is prone to occurring in the successive work transfer process, and cotton in the throw pillows is not evenly distributed are solved.

Owner:安徽情暖家具有限公司

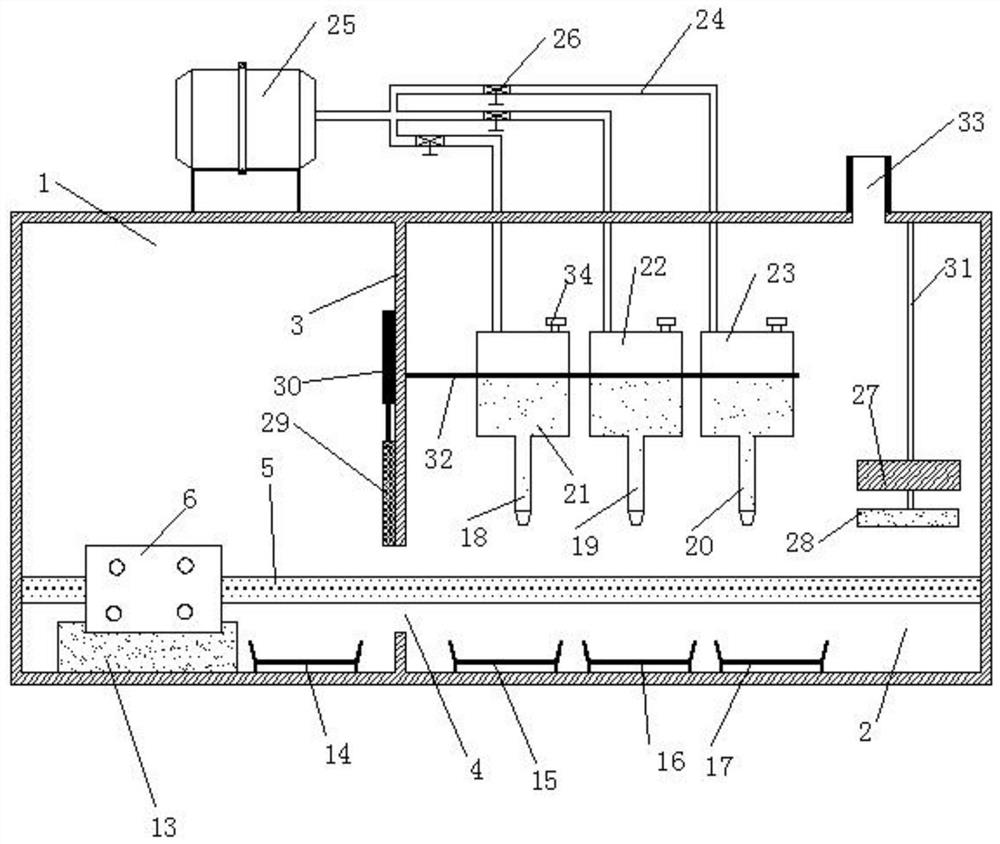

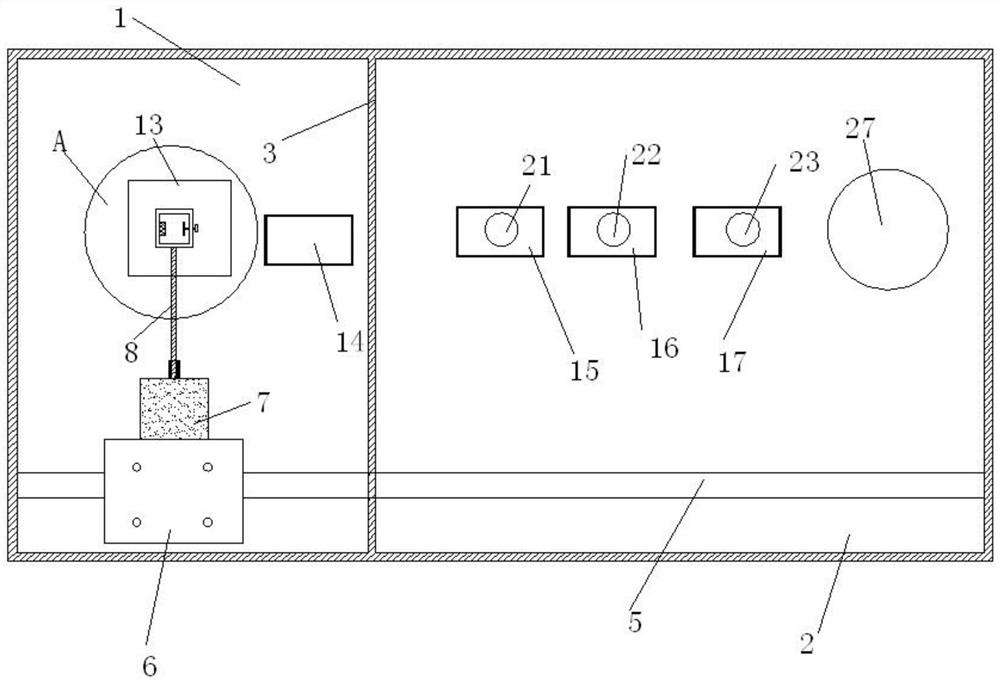

An automatic cleaning system for cuvette in laboratory processing

ActiveCN110918578BHigh degree of work automationSimple structureHollow article cleaningDrying gas arrangementsThermodynamicsElectric machine

The invention belongs to the cuvette cleaning device field and discloses an automatic cuvette cleaning system in laboratory treatment. The system comprises a working chamber and a cleaning chamber, asliding rail is connected between the working chamber and the cleaning chamber in a penetrating mode, a linear motor is arranged on the sliding rail, and a stepping motor is fixedly connected to the linear motor. The stepping motor is connected with a first connecting rod. A hollow box body is arranged at the other end of the first connecting rod. A second waste liquid tank, a third waste liquid tank and a fourth waste liquid tank are arranged in the cleaning chamber. A first liquid discharging pipe which is vertically arranged is arranged above the second waste liquid tank, a second liquid discharging pipe which is vertically arranged is arranged above the third waste liquid tank, and a third liquid discharging pipe which is vertically arranged is arranged above the fourth waste liquid tank. An exhaust fan with a downward air port is arranged on one side, away from the second liquid discharging pipe, of the third liquid discharging pipe, and an electric heating wire is arranged belowthe exhaust fan. The system is high in working automation degree, simple in structure, good in cleaning effect and high in application value.

Owner:合肥合大环境检测股份有限公司

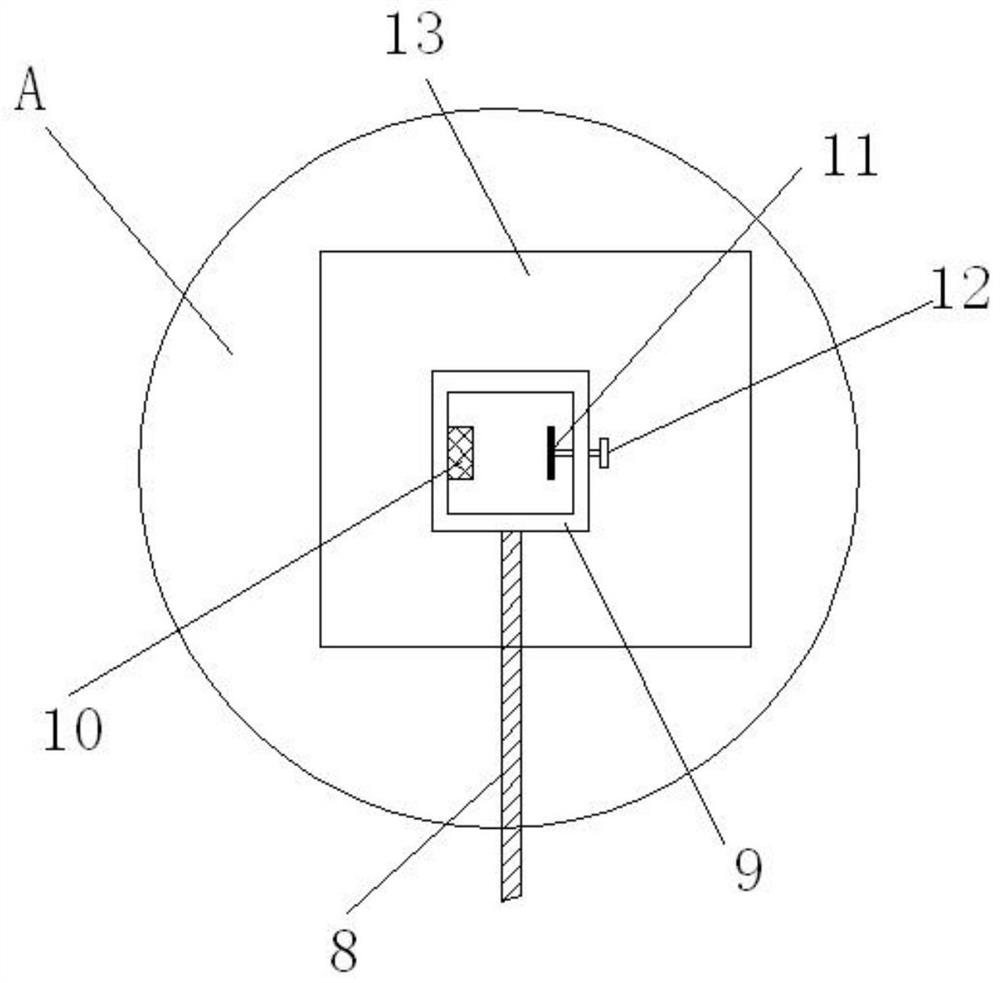

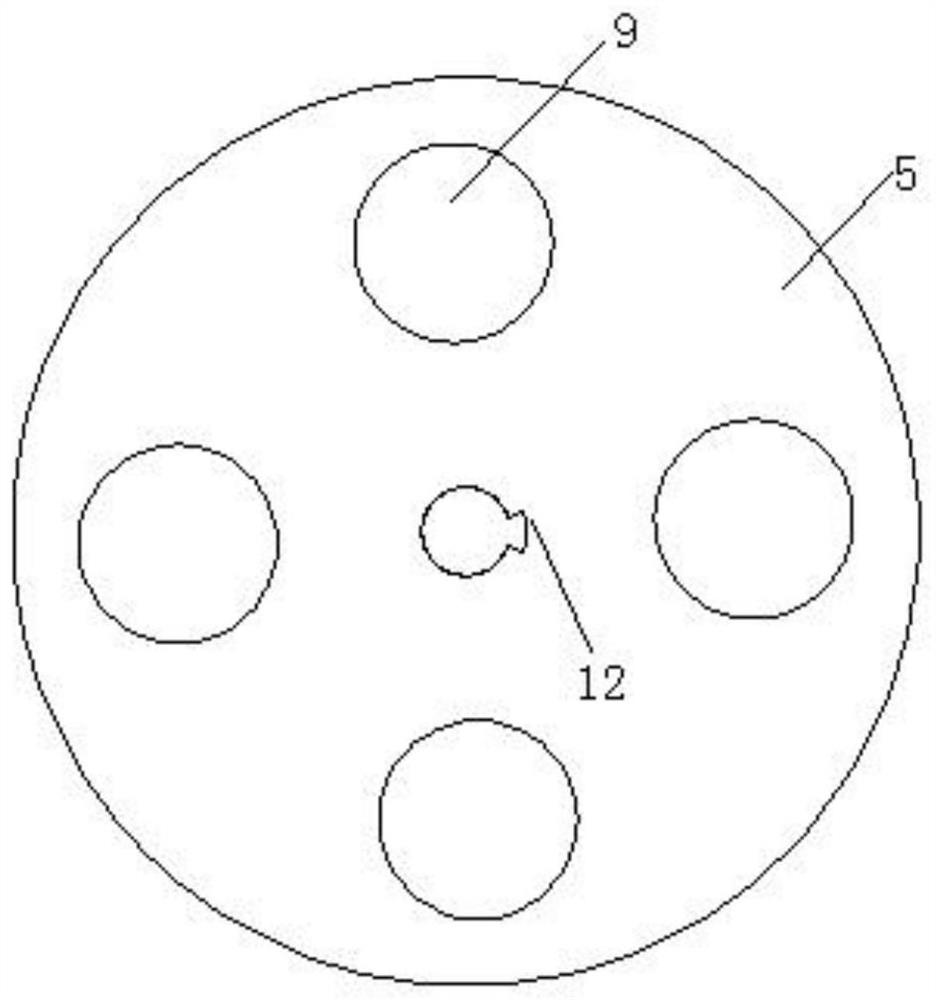

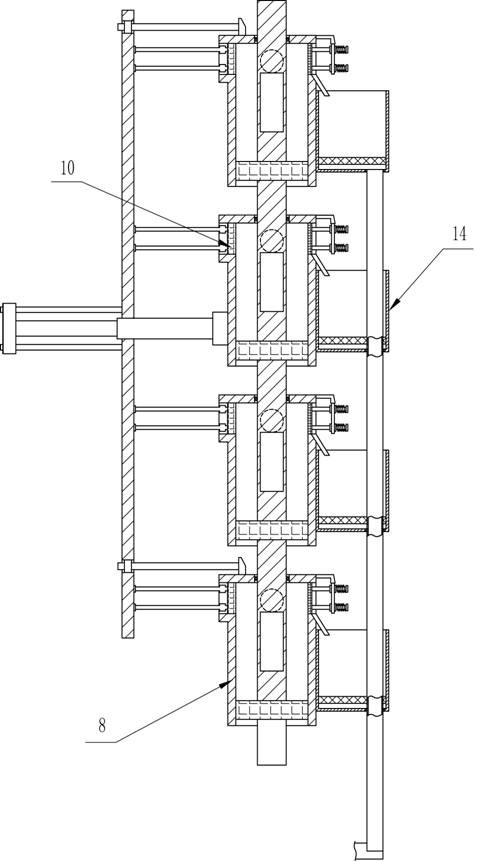

Petroleum perforating bullet four-station forming device

The invention belongs to the field of pressing and forming tools for petroleum perforating bullets and discloses a petroleum perforating bullet four-station forming device which comprises a device base and a stand column. The stand column is provided with a first fixing disc, a second fixing disc, a first forming disc and a second forming disc in a sleeved manner. The lower end of the first fixingdisc is connected with a first hydraulic oil cylinder. The upper end of the second fixing disc is connected with a second hydraulic oil cylinder. Four first forming grooves are uniformly formed in the lower end of the first forming disc. Four second forming grooves are uniformly formed in the upper end of the second forming disc. The cross section of the stand column is in a round structure, anda fool-proofing block is arranged at one end of the stand column. Fool-proofing holes are formed in the portions, sleeving the stand column, of the first fixing disc, the second fixing disc, the firstforming disc and the second forming disc. According to the device, pressure is applied to the two sides of the first forming grooves and the two sides of the second forming grooves at the same time,the density of obtained petroleum perforating bullets is more compact, internal cartridge bags are distributed more uniformly, and the effect of the obtained petroleum perforating bullets is better.

Owner:HEFEI HAIDE HYDRAULIC PRESS

A household sofa bed cushion processing and molding equipment

ActiveCN114031030BQuality improvementHigh degree of work automationUpholstery manufactureHome useMolding machine

The invention relates to a cushion processing and forming equipment for a household sofa bed, which includes a cotton filling mechanism, a forming mechanism and a collection box; the pillow is clamped by a clamping mechanism installed on a transmission mechanism to complete the automatic cotton filling work sequentially through the cotton filling mechanism, It is then transmitted to the forming mechanism to complete the work of breaking up the cotton-filled silk floss, and finally transmitted to the collection box to complete the automatic dropping of the pillow after forming; the forming mechanism includes a sewing assembly installed above the transmission mechanism, and the The beating assembly of the synchronous transmission of the sewing assembly and the snapping assembly that automatically snaps the pillow after the sewing assembly completes the sewing work; The post-sewing is two processes. In the process of successive work transfer, it is easy to have the phenomenon of cotton running and the technical problems of uneven distribution of cotton in the pillow.

Owner:安徽情暖家具有限公司

Continuous storage device for furniture gap blocking rubber strips

InactiveCN112623401AEasy to moveHigh degree of work automationBundling machine detailsAdhesive beltEngineering

The invention relates to a continuous storage device for furniture gap blocking rubber strips. The continuous storage device comprises a conveying mechanism, a traction mechanism, a winding mechanism, an output mechanism and a mold loading mechanism, wherein the conveying mechanism comprises an extruder and a cooling assembly; the traction mechanism comprises a clamping assembly and a supporting assembly; the winding mechanism comprises a hoop assembly arranged on one side of the supporting assembly and a cutting assembly which is in synchronous transmission with the hoop assembly and is used for slitting the rubber strips, and a clamping mold is placed on the hoop assembly; the output mechanism comprises a push-down assembly and a conveying belt; and the mold loading mechanism comprises a mold storage assembly arranged above the hoop assembly and a conveying assembly used for driving the mold storage assembly to automatically enter the hoop assembly. According to the continuous storage device, the technical problems that in the traditional packaging work of extruded and formed rubber and plastic rings, the rubber and plastic rings are packaged by adopting a rope or adhesive tape bonding mode, but due to the fact that the size of the rubber and plastic rings is large, the packaging work is not firm, the rope is prone to breakage in the carrying process, and the packaging effect is poor are solved.

Owner:浙江笙龙家具有限公司

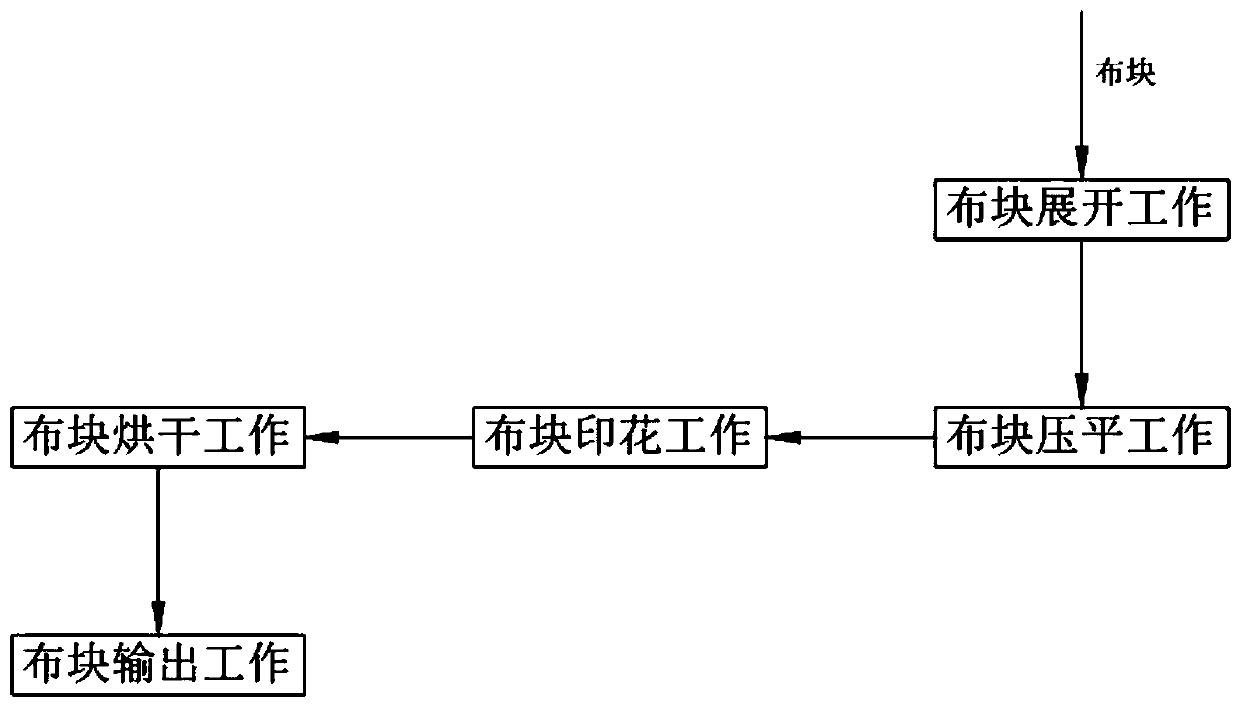

Fabric color printing process

InactiveCN111152552AAvoid creases and bulgesDries fast and wellRotary pressesPrinting press partsTextile printerColor printing

The invention relates to a fabric color printing process. The fabric color printing process comprises the following steps that 1, cloth pieces are unfolded; 2, the cloth pieces are flattened; 3, thecloth pieces are printed; 4, the cloth pieces are dried; and 5, the cloth pieces are output, specifically, after the cloth pieces are dried, the cloth pieces are manually and rapidly taken away, afterthe cloth pieces are manually taken away, a filling plate and a buckle unit are rapidly reset, and when a conveying trolley moves to the end part of an output part, a signal is rapidly sent to the conveying trolley, so that the conveying trolley is rapidly reset, and when cloth pieces on a next cloth receiving plate are flattened, conveying of the next cloth receiving plate is waited. The fabriccolor printing process solves the technical problem that the elasticity of a T-shirt is affected due to the fact that fabric is in a tensioned state for a long time in the conveying process.

Owner:长兴创智科技有限公司

Weft knitting hosiery machine with integrated hosiery sewing head and using method

ActiveCN104611823BHigh degree of work automationMechanical cleaningPressure cleaningEngineeringThrough transmission

The invention discloses a hosiery knitting and end sewing integrated weft knitting hosiery knitter. A control panel is arranged on an electric control box. A working table is installed on a working box and provided with a hosiery knitting machine, a hosiery turning device, a mechanical arm and an end sewing machine. The mechanical arm is located between the hosiery knitting machine and the hosiery turning device. The hosiery turning device and the end sewing machine are located on the same straight line. The hosiery knitting machine is connected with a main motor through a conveying belt. The hosiery turning device is connected with a hosiery turning rod lifting motor and a tongs lifting motor through transmission devices respectively. A pair of mechanical arm tongs is installed on the mechanical arm. The mechanical arm is connected with a rotating motor through a worm and a gear. The end sewing machine is connected with an end sewing motor through a driving belt. The control panel is connected with the main motor, the hosiery turning rod lifting motor, the rotating motor and the end sewing motor through circuits respectively. An air suction pipe is arranged on the hosiery turning device and provided with a hosiery outlet cover. Thus, the hosiery knitting work, the hosiery turning work and the end sewing work can all be completed at a high automation degree.

Owner:诸暨镭尔福机械科技有限公司

Accessory post-processing equipment for alternating-current low-voltage power distribution cabinet

InactiveCN114014101ARealize automatic switchingHigh degree of work automationFilament handlingControl theoryMachining process

The invention relates to accessory post-processing equipment for an alternating-current low-voltage power distribution cabinet. The accessory post-processing equipment comprises a driving mechanism, a first winding mechanism; a first slitting mechanism; a second winding mechanism, wherein a rotating assembly b is sequentially provided with a second output station, a second input station and a second winding station in the circumferential rotating direction of the rotating assembly b; a second slitting mechanism; and a horizontal pushing mechanism which drives a supporting assembly a and a supporting assembly b to horizontally move and alternately transmit. The formed sealing strips are output from the position between the first winding mechanism and the second winding mechanism, winding work switched from the first winding mechanism to the second winding mechanism is completed in the output process, and continuous automatic packaging of the sealing strips is achieved. The technical problems that in the machining process of the sealing strips, shutdown is needed for winding work, the wound sealing rings are automatically collected, and thus the working efficiency is low are solved.

Owner:温州市康达电气成套设备有限公司

Intelligent guiding arranging device for lens placing machine

InactiveCN111807046AHigh degree of automationGuarantee the quality of workConveyorsConveyor partsFixed frameBoth lenses

The invention relates to an intelligent guiding arranging device for a lens placing machine. The device comprises a rack, foot stands, fixing frames and a placing machine feeding device, wherein the foot stands are evenly arranged at the bottom end of the rack, the fixing frames are symmetrically arranged on the top face of the rack, telescopic rods are arranged at the top ends of the fixing frames correspondingly, a vertical plate is arranged between the telescopic rods, a sliding groove is formed in the front end of the vertical plate, the placing machine feeding device is arranged in the sliding groove, a first placing box is arranged at the left end of a table board of the rack, and a second placing box is arranged on the right side of the first placing box. According to the scheme, the two lens placing boxes are arranged at the bottom end of a lens discharging device, the discharging device can continuously and alternately carry out lens placing on the two lens placing boxes, andwhen the discharging device continuously conveys lenses to the positions above the placing boxes, a transmission disc drives the placing boxes to move by a corresponding distance on the rack so as tobe matched with the placing operation of the discharging mechanism, so that the automation degree of lens placing is improved, and the working quality of lens placing is ensured.

Owner:宁波丞达精机股份有限公司

A sewage treatment equipment for environmental protection

ActiveCN112090167BReduce processing costsAvoid cloggingTreatment involving filtrationMultistage water/sewage treatmentSewageWaste water treatment plant

The invention discloses environment-friendly sewage treatment equipment which comprises a pressure pipe and a connecting box, wherein the pressure pipe and the connecting box are provided with a flowdividing device, a starting and stopping device, a removing device, a lifting device, a transmission device and a driving device; a connecting box is fixedly connected to one side of the pressure pipe, a communicating pipe is fixedly connected to the other side of the connecting box, external connecting pipes are connected into the communicating pipe and the other side in the pressure pipe in a sealed mode, a wall hanging frame is fixedly connected to one side of the pressure pipe, and a water pressure gauge is connected to the position, away from one side of the connecting box, of the pressure pipe in a sealed mode. At least one mounting frame is fixedly connected to the side, away from the wall hanging frame, of the pressure pipe. Through cooperation of the flow dividing device, the starting and stopping device, the removing device, the lifting device, the transmission device and the driving device, the efficiency in the sewage treatment process is improved, a pipeline cannot be blocked in the sewage conveying process, the environmental protection property is improved, and the workload of a sewage treatment plant is reduced.

Owner:河南正远化工有限公司

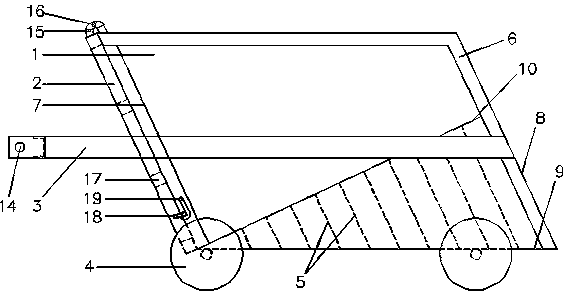

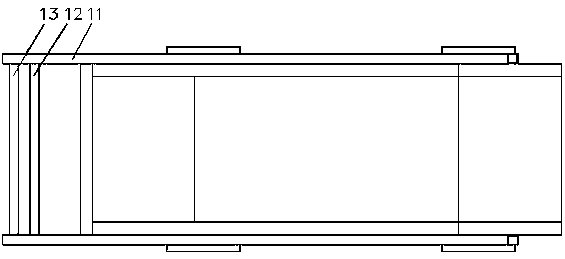

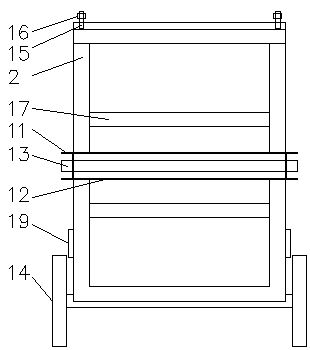

Unpowered slag unloading trolley

ActiveCN106437836BImprove securityImprove stabilityEarth drilling and miningUnderground transportEngineeringTruck

The invention discloses an unpowered slag unloading trolley. The slag unloading trolley comprises a trolley body, a trolley door and wheels, and the trolley door and the wheels are arranged on the trolley body. The trolley body is provided with a trolley upper bottom face and a trolley lower bottom face, and a counterweight layer is arranged between the trolley upper bottom face and the trolley lower bottom face. A trolley front side face and a trolley rear side face are arranged at the two ends of the trolley body in parallel. The included angle between the trolley upper bottom face and the trolley lower bottom face, the included angle between the trolley front side face and the vertical direction and the included angle between the trolley rear side face and the vertical direction are equal to the included angle between an inclined shaft and the horizontal plane. The trolley door is arranged on the trolley front side face and is hinged to and connected with the front side face. When the unpowered slag unloading trolley runs in the inclined shaft, the four side faces are kept in the vertical state, and running safety and stability of the trolley are improved; a slag unloading platform on the opening of the inclined shaft is arranged as a slope, and the angle of the slope is smaller than that of the inclined shaft; during slag loading, after the trolley door is opened, slag can automatically slide out from the trolley; after the slag is unloaded, the trolley can automatically move backward by means of gravity of the trolley and counterweights, and the trolley can conveniently enter the preparation state for next time of work without power.

Owner:中铁十八局集团第二工程有限公司 +1

Clamping groove forming and cutting device for aluminum alloy clamping hoop machining and working method thereof

InactiveCN110303202AStable and reliable deliveryAvoid damageMetal working apparatusEngineeringMechanical engineering

The invention discloses a clamping groove forming and cutting device for aluminum alloy clamping hoop machining. The clamping groove forming and cutting device comprises a mounting base, a conveying and receiving platform, a swing seat, a rotary adjusting disc and grooving frames, the conveying and receiving platform is horizontally arranged on one side above the mounting base, the swing seat is arranged at one end of the conveying and receiving platform, and the round rotary adjusting disc is arranged on one side of the swing seat. The clamping groove forming and cutting device has the beneficial effects that motors VII drive clamping jaws to swing and adjust, so that the distance between the two clamping jaws at the two ends of each movable clamping seat is adjusted, it is ensured that clamping hood with different shapes and widths can be clamped and fixed for cutting work of the clamping grooves by the device, and the adaptive universality is guaranteed; shifting seats are embeddedin rails of hanging rails through motors X to drive rotary cutting pieces to move forwards and backwards to adjust the positions, and the rotary cutting pieces are driven to adjust the positions up and down under the cooperation of hydraulic oil cylinders II to drive the rotary slice to move up and down, therefore, on one hand, it is ensured that the ranges of the positions, where adjustment can be achieved and the clamping groove structures can be formed and cut, of the clamping hoops are wider, and on the other hand, the position precision for forming and cutting the clamping grooves on theclamping hoops through the device is greatly improved.

Owner:东莞市棱锐包装材料有限公司

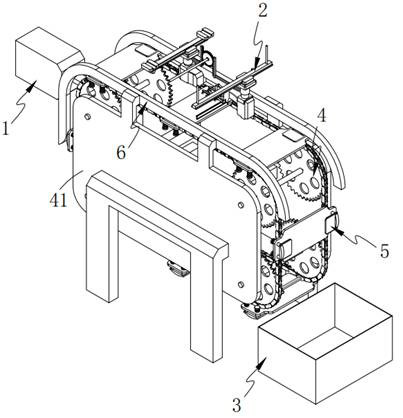

Cake fetching device for algae material processing

ActiveCN102763869BHigh degree of work automationWork reliablyConveyor partsFood scienceEngineeringRelative motion

The invention provides a cake fetching device for algae material processing. The device comprises a first frame assembly, a second frame assembly, a cake fetching member and a rack. By mutual extrusion and extrusion relief motions of the claw-type cake fetching member installed on the first frame and an interacting member installed on the second frame, and with the cooperation of vertical movement and relative movement of the first and second frames, the lower end of the claw-type member spreads or contracts to fetch a material cake in a material tray, and the material cake is sent out of the unit through a discharging assembly. The device provided by the invention is one of the key technological devices for realizing operational automation of algae material processing units, and has technical characteristics of simple structure, reliable operation, stable performance and high degree of automation.

Owner:LIANYUNGANG FUAN LAVER MACHINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com