Hosiery knitting and end sewing integrated weft knitting hosiery knitter and use method

The technology of a hosiery machine and a sewing machine is applied in the field of weft knitting hosiery machine, which can solve the problems of wear, large loss, complicated operation, etc., and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

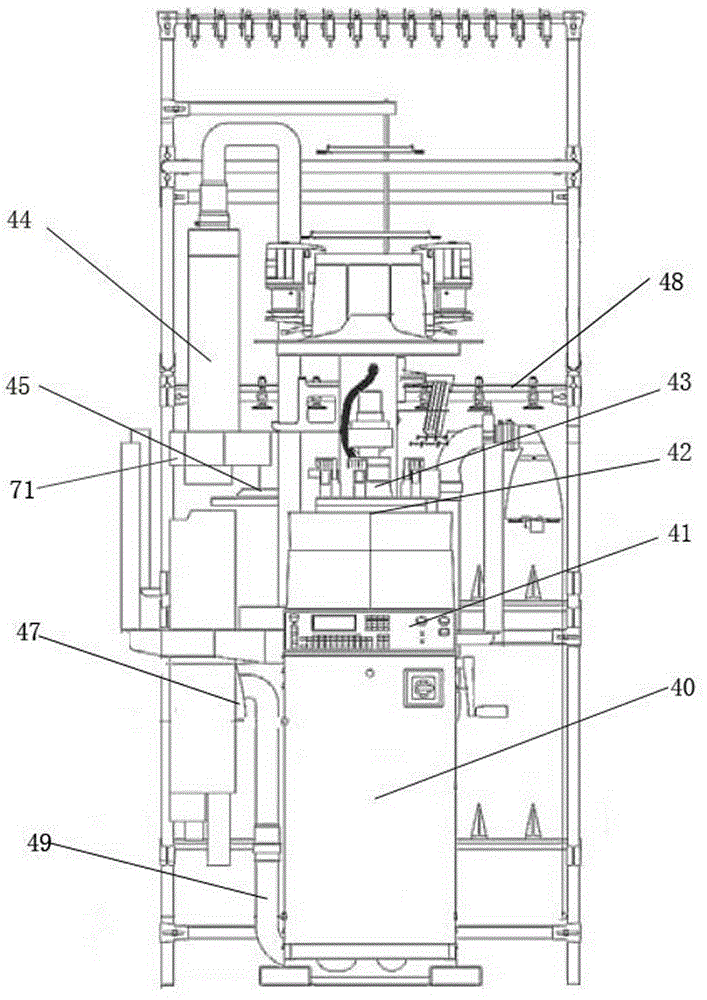

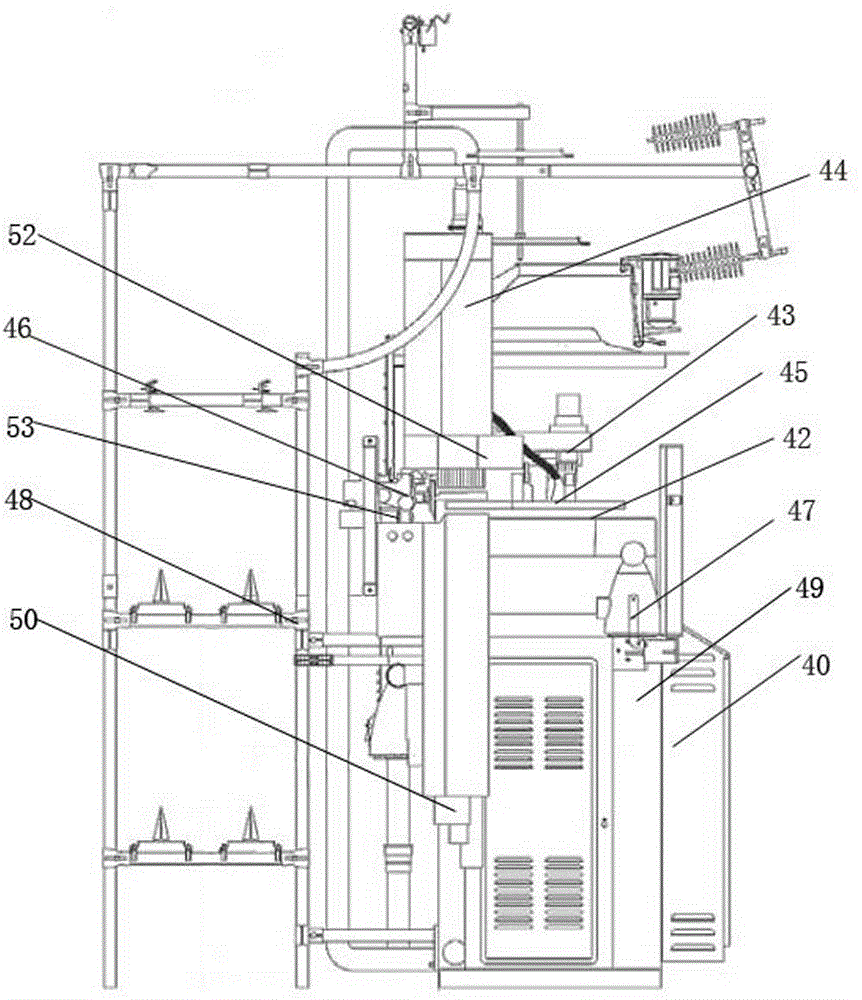

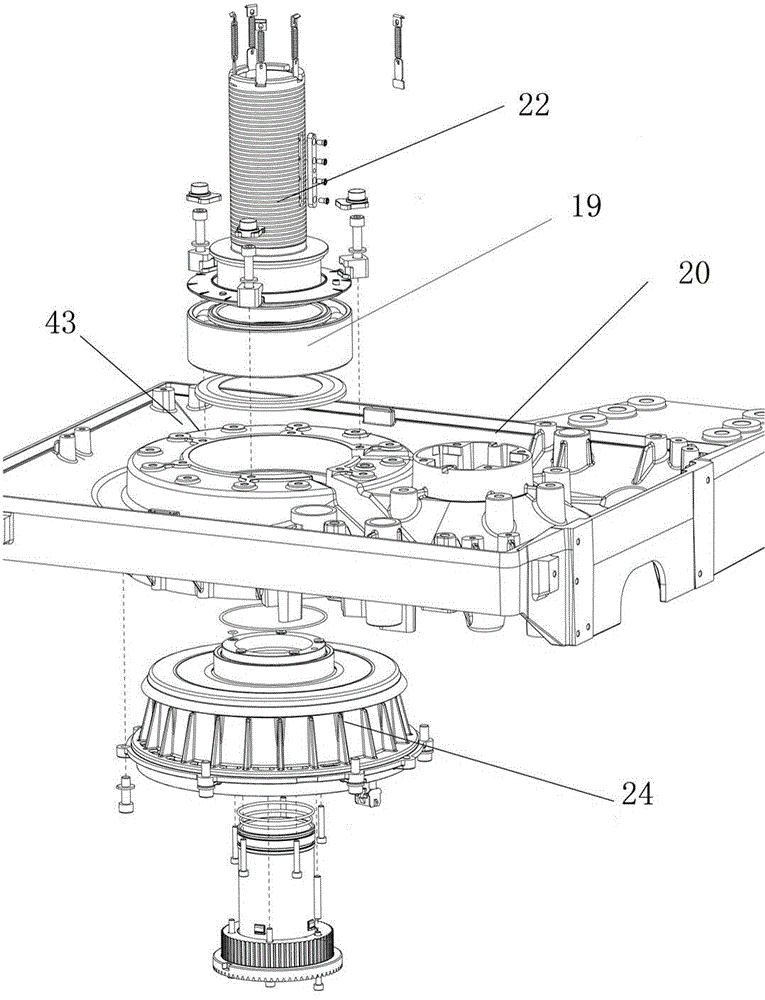

[0032] Such as Figure 1-10 A weft knitting hosiery machine with integrated hosiery sewing head is shown, comprising an electric control box 40, a control panel 41 is installed on the electric control box 40, a workbench 42 is installed on the workbox 40, and the workbench 42 is respectively equipped with sock knitting machine 43, sock turning device 44, mechanical arm 45 and sewing machine 46, and described mechanical arm 45 is positioned between sock knitting machine 43 and sock turning device 44, and described sock turning device 44 is connected with seam The head machine 46 is located on the same straight line, the sock knitting machine 43 is connected with the main motor 24 through a transmission belt, the sock turning device 44 is respectively connected with the sock turning rod lifting motor 50 and the gripper lifting motor 59 through a transmission device, and the mechanical arm A mechanical arm gripper 60 is installed on the top, the mechanical arm 45 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com