Unpowered slag unloading trolley

A trolley and slag unloading technology, which is applied in transportation and packaging, earth drilling, underground transportation, etc., can solve the problems of prolonging the construction period, many auxiliary construction personnel, and short excavation length, and achieve the effect of enhancing safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment, further illustrate the present invention.

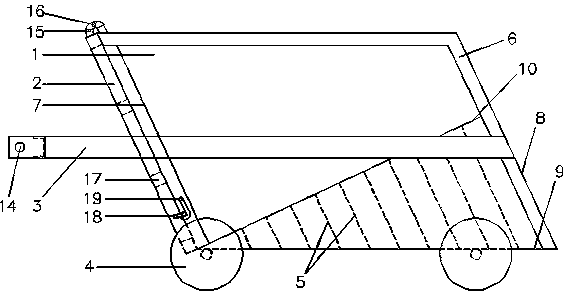

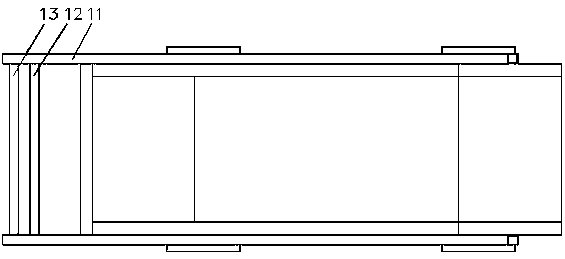

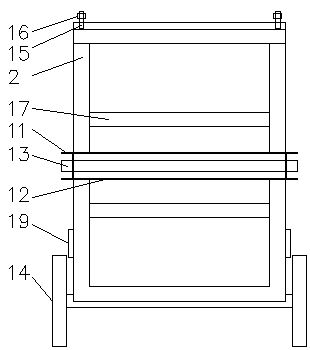

[0022] see figure 1 - image 3 , a non-powered slag unloading trolley, consisting of a car body 1, a car door 2 arranged on the car body 1, and wheels 4. Between the bottom surfaces 9 is a counterweight layer; the front side 7 of the trolley and the rear side 8 of the trolley are arranged at both ends of the car body 1 in parallel; The included angle with the vertical direction is equal to the included angle between the inclined shaft and the horizontal plane, the car door 2 is arranged on the front side 7 of the trolley, and the car door 2 is hingedly connected with the front side.

[0023] The car body 1 is made of steel plates, which are fixed together by welding. The steel plates are welded with double angle steels 6 around them for reinforcement. The upper part of the bottom surface 9 of the trolley is welded with a reinforcement plate 5 every 15 cm. The reinforcement plates 5 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com