Accessory post-processing equipment for alternating-current low-voltage power distribution cabinet

A power distribution cabinet and post-processing technology, which is applied in the field of power distribution cabinet accessories, can solve the problems of needing to stop for winding work and low work efficiency, and achieve the effect of simple structure, high linkage, and linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

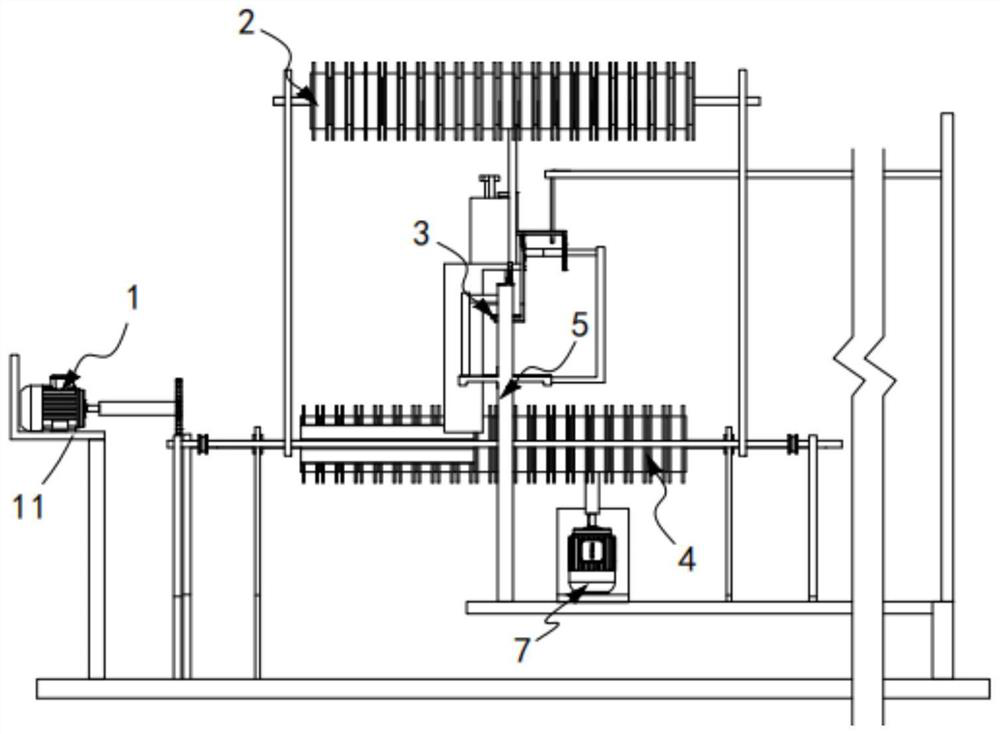

[0065] Such as figure 1 As shown, a post-processing equipment for accessories for AC low-voltage power distribution cabinets, including:

[0066] A drive mechanism 1, the drive mechanism 1 comprising a frame 11, a drive motor 12 mounted on the frame 11 and a drive wheel 13 arranged at the output end of the drive motor 12;

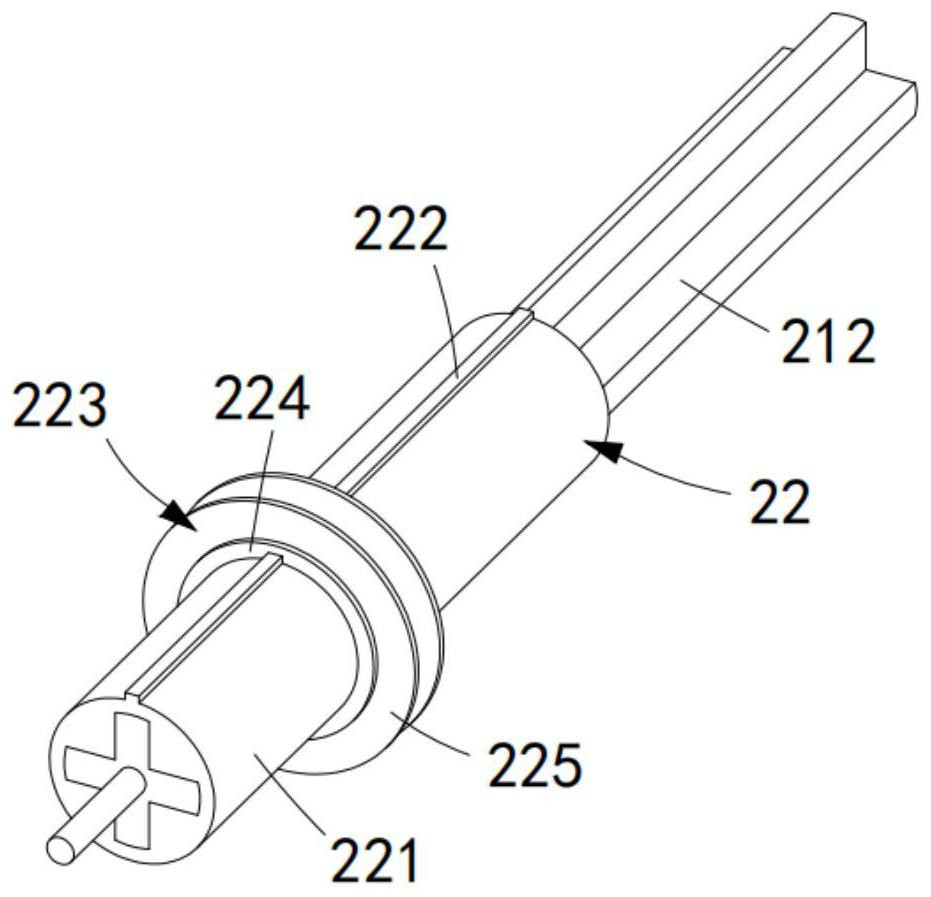

[0067] The first winding mechanism 2, the first winding mechanism 2 includes a rotating assembly a21 that cooperates with the driving mechanism 1 to perform circular rotation, and the rotating assembly a21 is sequentially provided with a first output station 20a along the direction of its circular rotation . The first input station 20b and the first winding station 20c, the rotating assembly a21 is provided with three sets of support assemblies a22 arranged in sequence on the rotating assembly a21 along the horizontal direction;

[0068] The first slitting mechanism 3, the first slitting mechanism 3 includes a first identification component 31 arranged on ...

Embodiment 2

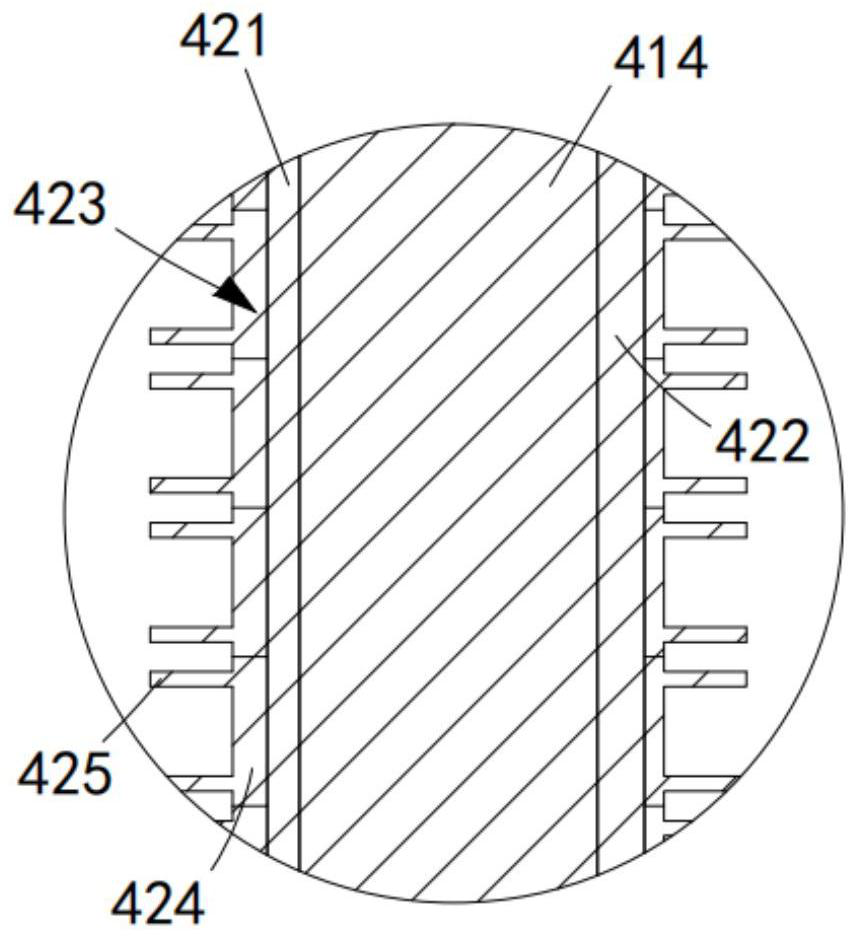

[0119] Such as Figure 10 , Figure 11 to Figure 14 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0120] further, such as Figure 10 As shown, the horizontal pushing mechanism 7 includes a first traction assembly 71 coaxially arranged with the first winding mechanism 2, a second traction assembly 72 coaxially arranged with the second winding mechanism 4, and a driving assembly The first traction assembly 71 and the second traction assembly 72 are synchronously switched rotating members 73;

[0121] The first traction assembly 71 and the second traction assembly 72 are oppositely arranged, and each of them includes a pull rod a711 and a stopper that are arranged in an L-shaped structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com