Mixing stirrer for medium-hardness heat vulcanized heat conduction silicone rubber and preparation process

A heat-conducting silicone rubber and preparation technology, which is applied in the field of silicone rubber mixers, can solve problems such as difficult cleaning of the barrel body, uneven mixing, waste of human resources, etc., achieve simple and easy working principle, simple and reasonable structural design, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

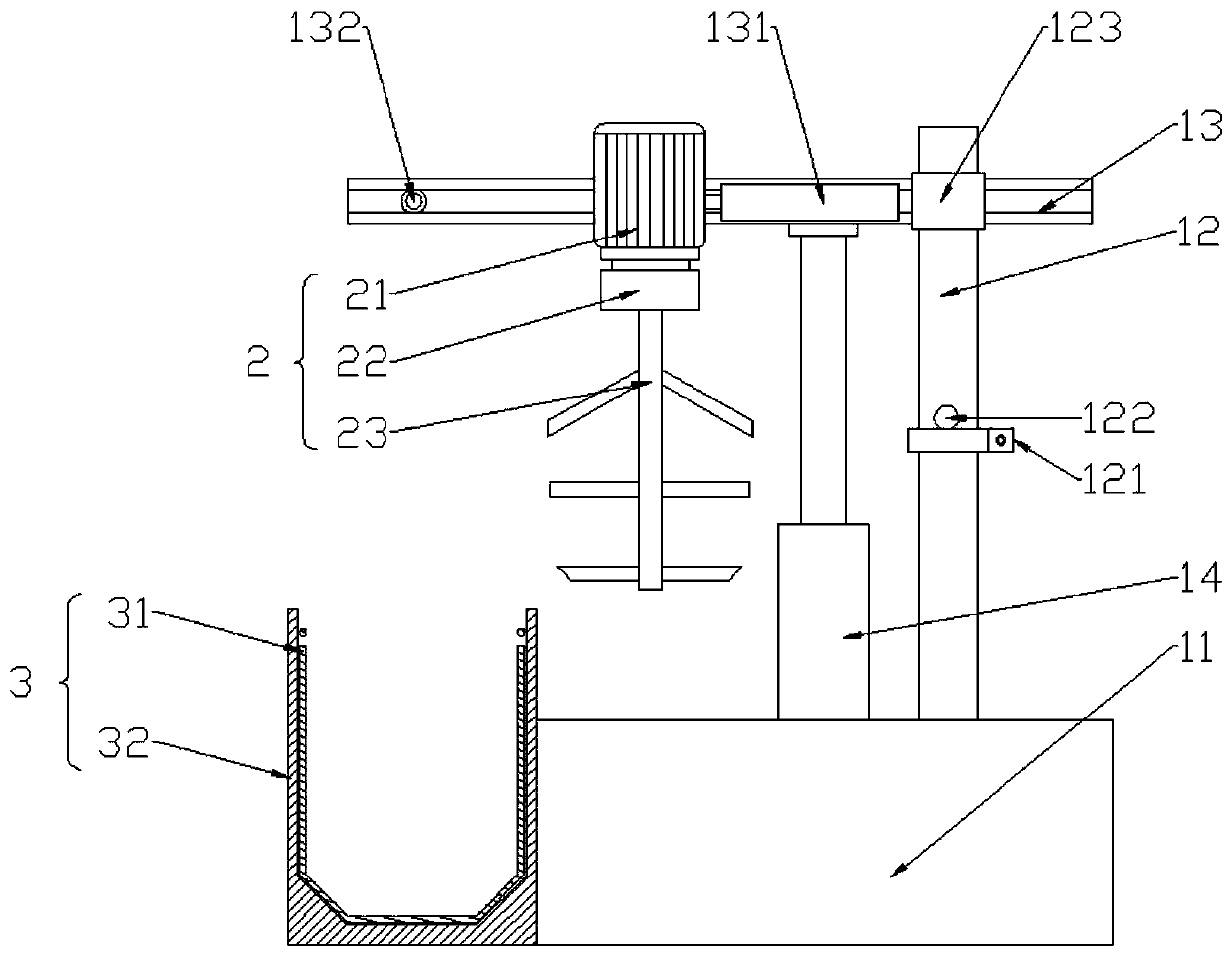

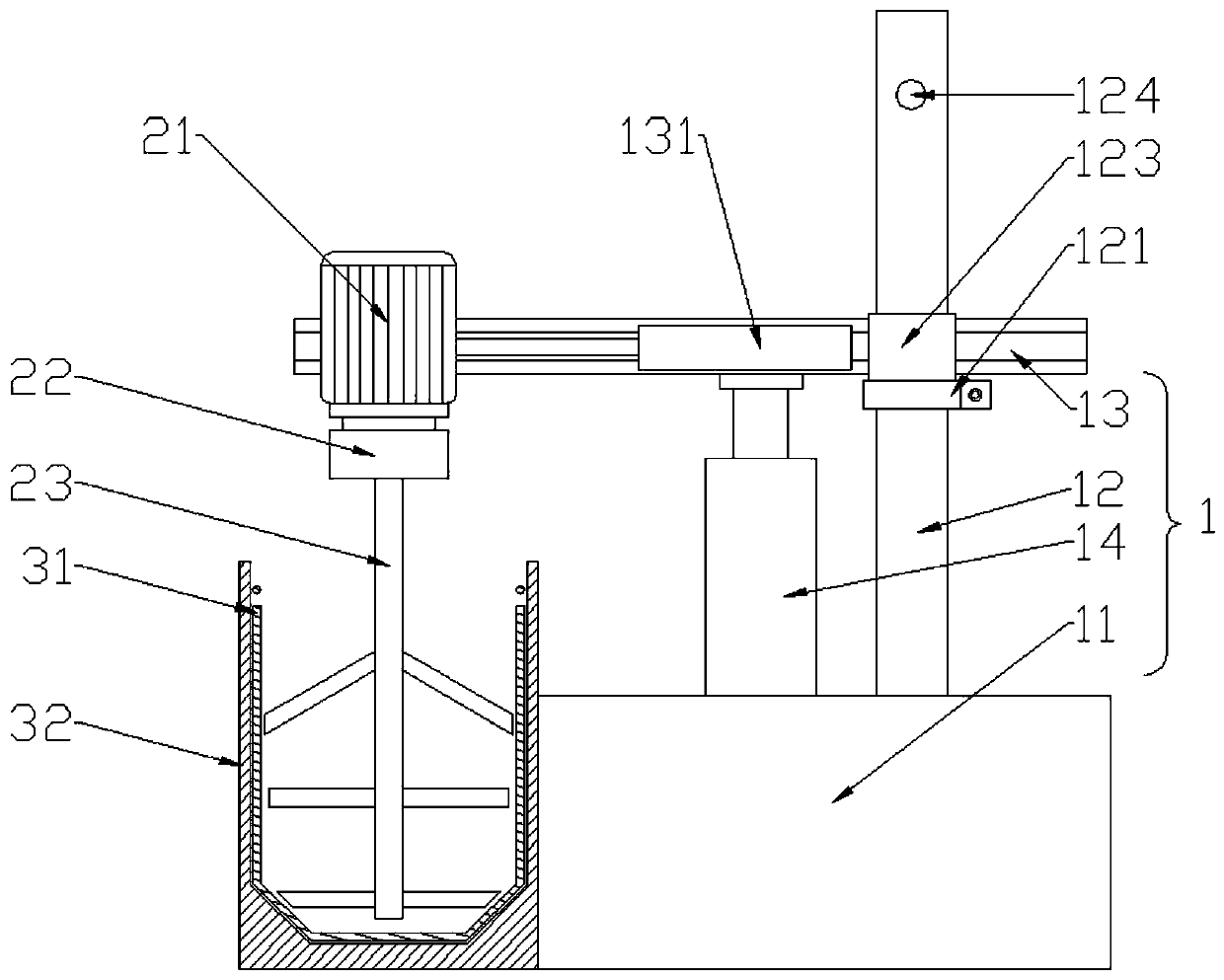

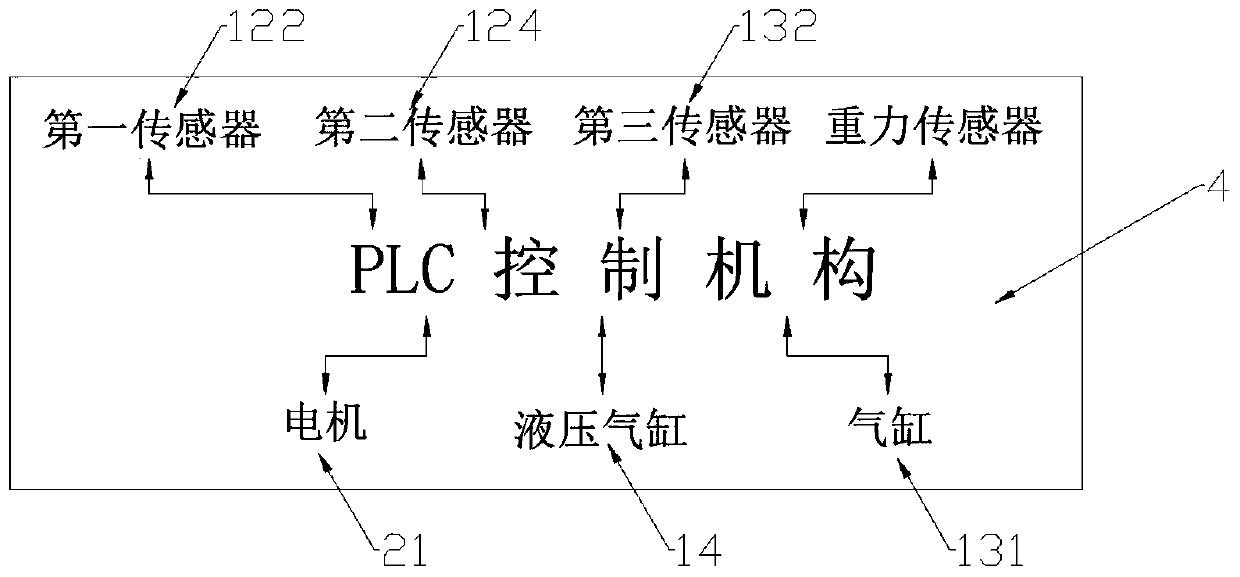

[0031] like Figure 1-2 The mixing mixer and preparation process for medium-hardness heat-vulcanized heat-conducting silicone rubber shown includes: a frame 1, a stirring component 2, and a stirring material container component 3, and the stirring component 2 is arranged on the frame 1, and the stirring material container The component 3 is arranged on the side of the frame 1 close to the stirring component 2 . The frame 1 includes: a base 11, a guide post 12, a moving beam assembly 13, and a hydraulic cylinder 14, the guide post 12 is vertically arranged on the upper end of the base 11; the moving beam assembly 13 is vertically connected to the guide post 12; The hydraulic cylinder 14 is arranged on the top of the base 11, and the upper end of the hydraulic cylinder 14 is connected with the moving beam assembly 13; the stirring assembly 2 includes: a motor 21, a gearbox 22, and a stirring shaft 23, and the motor 21 is directed downwards in the direction of the rotor. It is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com