Continuous storage device for furniture gap blocking rubber strips

A storage device and rubber strip technology, applied in the directions of packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of insecure packaging work, large size of rubber and plastic rings, poor packaging effect, etc., achieving a high degree of automation and saving Production cost and ease of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

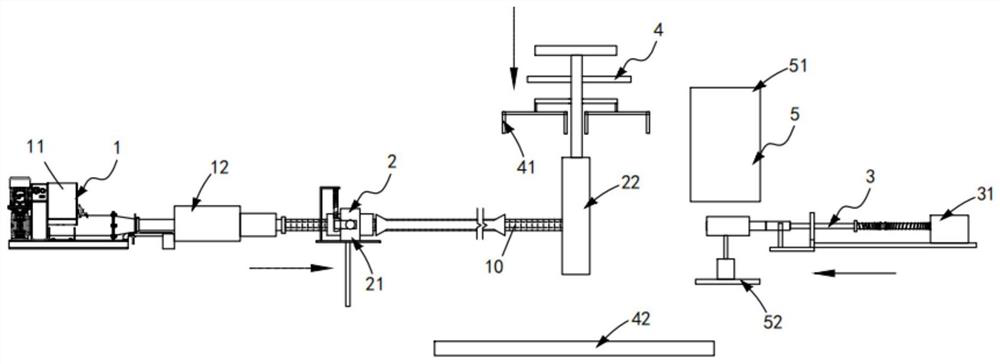

[0068] Such as figure 1 As shown, a furniture gap sealing rubber strip continuous storage device, including:

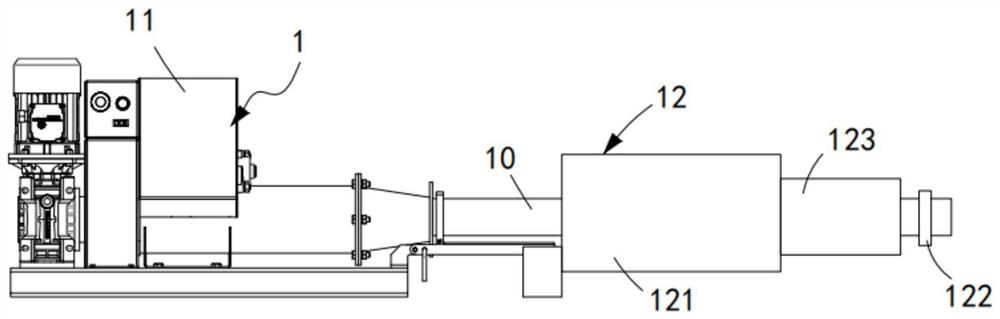

[0069] A transmission mechanism 1, the transmission mechanism 1 comprising an extruder 11 and a cooling assembly 12 arranged at the output end of the extruder 11;

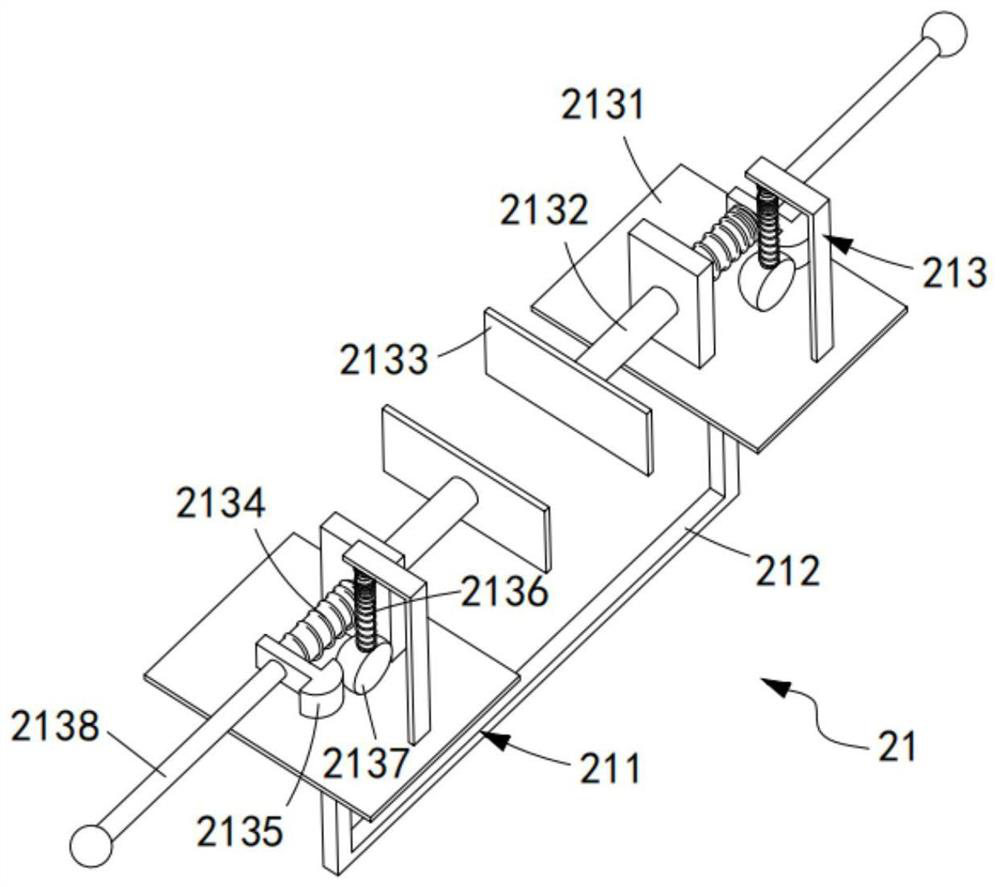

[0070] A traction mechanism 2, the traction mechanism 2 includes a clamping component 21 disposed at the output end of the cooling component 12 and a support component 22 disposed on one side of the clamping component 21 and matched with the clamping component 21;

[0071] The winding mechanism 3, the winding mechanism 3 includes a hoop assembly 31 arranged on one side of the support assembly 22 and a cutting assembly synchronously driven with the hoop assembly 31 and used for cutting the rubber strip 10 32. A clamping mold 33 is placed on the hoop assembly 31;

[0072] The output mechanism 4, the output mechanism 4 includes a push-down assembly 41 arranged directly above the support assembly 22 and a tr...

Embodiment 2

[0112] Such as Figure 13 to Figure 17 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0113] further, such as Figure 13 to Figure 15 As shown, the hoop assembly 31 includes:

[0114] A driving cylinder 311, the driving cylinder 311 is installed on the cylinder frame and its output end slides along the vertical direction and is provided with a telescopic unit c312;

[0115] A connecting frame b313, the connecting frame b313 is fixedly connected to the other end of the telescopic unit c312;

[0116] The connecting plate a314, the connecting plate a314 is slid and arranged on the cylinder frame along the vertical direction through two sets of telescopic units d315;

[0117] Tightening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com