A household sofa bed cushion processing and molding equipment

A processing molding and sofa bed technology, applied in the field of furniture, can solve the problems of running cotton, uneven distribution of cotton in pillows, etc., achieve high degree of automation, simple structure, and improve the effect of molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

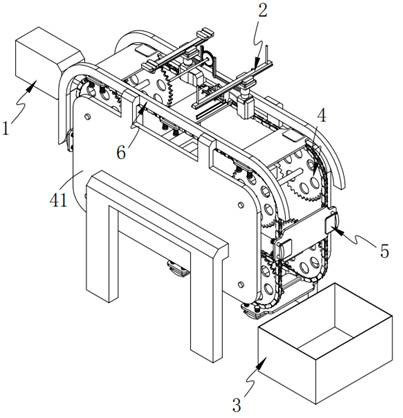

[0043] like figure 1 As shown, a household sofa bed cushion processing and forming equipment includes a cotton filling mechanism 1, a forming mechanism 2 and a collection box 3;

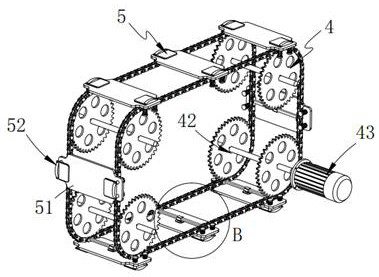

[0044] Clamped by the clamping mechanism 5 installed on the transmission mechanism 4, the pillow 101 passes through the cotton filling mechanism 1 to complete the automatic cotton filling work, and then transfers to the forming mechanism 2 to complete the cotton-filled silk floss breaking work, and finally transmits to the collection box The body 3 completes the automatic drop work of the pillow 101 after forming;

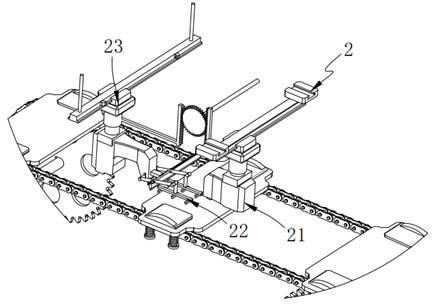

[0045] The forming mechanism 2 includes a sewing assembly 21 installed above the transmission mechanism 4, a beating assembly 22 synchronously driven with the sewing assembly 21, and a button that automatically snaps the pillow 101 after the sewing assembly 21 completes the sewing work. Buckle assembly 23.

[0046] In this embodiment, by setting the clamping mechanism 5 to cooperate wit...

Embodiment 2

[0072] like Figure 9 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0073] further, such as Figure 9 As shown, the buckle assembly 23 includes a second truss 231, a telescopic unit 232 vertically arranged at the lower end of the second truss 231, and a buckle machine 233 arranged below the telescopic unit 232;

[0074] The sewing assembly 21 drives the buckle assembly 23 to start intermittently through the second transmission assembly 24, and the second transmission assembly 24 includes a first transmission rack 241 fixedly connected to the second drive unit 213, and a first transmission rack 241 connected to the first A transmission rack 241 meshes with a first transmission gear 242...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com